400 posts already?

Wow - time flies lol *shrug* I've had the usual delays and setbacks that are part n'parcel with these things... but fortunately nothing that had anythin' to do with the project save not bein' able to work on it as much as I'd like. (ona side note - doggies rule trufax!).

Well... I guess I had a setback heh - I've decided that while I

could persevere and get my fenders to some semblance of rounded, I just haven't the fortitude that silverbear has and I've decided to replace them, using the originals only for hand painting the detailing practice (which I need desperately - it's been a looooong time lol). I did give it a shot... actually quite a number of attempts, but I came to the realization that not only is there

nothing "special" or different about them in any way - I kinda really want the

Duck Tail Fenders style for this, to help "age" the build.

Here's

some of the tappin' and filling attempt (click to view);

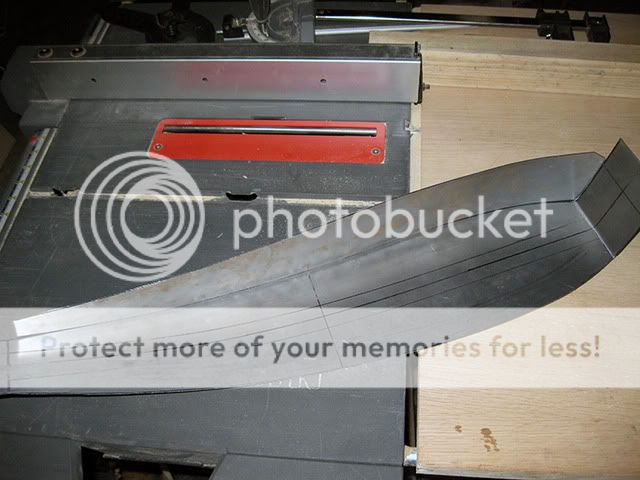

Onto the joys of tank building - while you can easily bend 20ga mild steel with your bare hands, there's no way to control the amount, location, or uniformity that way. To make matters more interesting should you overbend or do it wrong - the metal has a "memory" of sorts and it's dang hard to get it back to

perfectly flat. While it's ofc fine to do long, gradual curves by hand, for sharp, uniform bends with a predictable shape it's best to make yerself a DIY sheet metal brake (or buy a lil one, they're cheap... but I'm even cheaper lol:

sheet metal brake - Google Product Search).

As this is just a lil project and somewhat narrow bends, just two chunks of angle steel works great. I've welded flatstock to these with C-clamp heads for heaver gauge bends - for something like this tank it's not really needful tho. For sharp bends I use the other piece of angle steel (the sharp bend coulda been "sharper" in the pic but was just an example), for rounded bends I find some pipe or something of the correct diameter to use instead (in this case a plunger handle) The square block is jus' to prop it up for the pics - you'll need room for the metal to bend up to a 90 degree angle, depending on what you're doing;

A warning however - while the sharp bends with the two chunks of angle steel will always be right on the line, with one angle and a round it seems to always place the bend on the tailing end. In any case the bend itself takes up room so you should

always make lines and do a few trial bends on a scrap chunk to see where/how much you need to offset your marks.

Under bending is fine as you can just do it more (spacing out the next bend can also give you a larger radius than you have pipe for... but that's tricky), but over bending can spell doom. Do NOT just try to free-hand it back, the metal will develop a waver right next to the bend your trying to flatten - it's best to clamp it in two pieces of flat stock (at least twice as thick as what you're working) and squish it flat with a clamp or two. If it's close - put those

next to the bend (on the side you don't wanna mess up, or both) then give it a couple, gentle presses to "urge" it back.

More pics and progress to come