Thanks for the encouragement matt, I did figure it out. It took some doing, but it was well worth it.

Here's the parts I fabbed up and a T handle I had lying around.

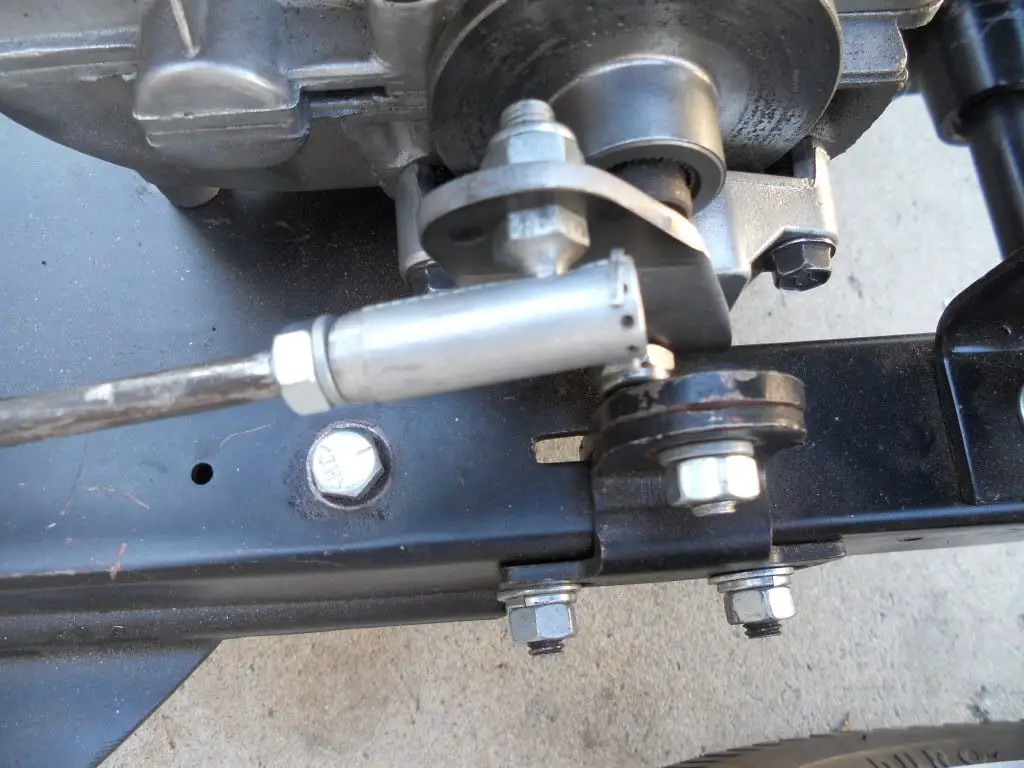

Got them all welded up and installed.

The gear indicator lines up perfect.

Just pull the lever and a pin comes up and lets it go into reverse.

Worked out better than I had hoped. Sometimes you get lucky. Now it's on to the dash and foot controls.

Here's the parts I fabbed up and a T handle I had lying around.

Got them all welded up and installed.

The gear indicator lines up perfect.

Just pull the lever and a pin comes up and lets it go into reverse.

Worked out better than I had hoped. Sometimes you get lucky. Now it's on to the dash and foot controls.