BarelyAWake

New Member

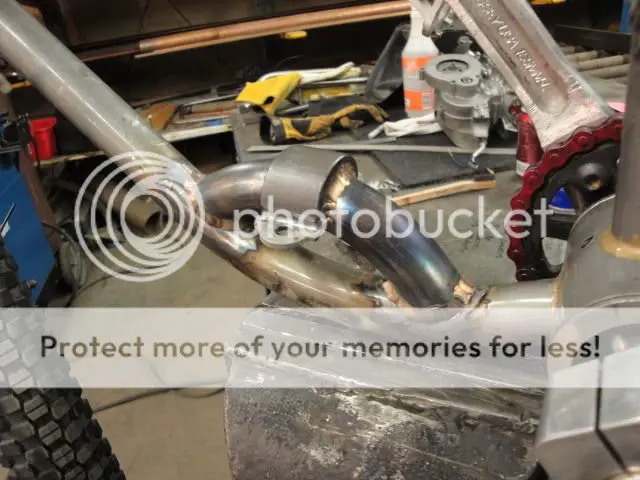

...upon looking at these photos now, i see that i need to slide the rear motor mount up on the seat tube at least an inch...

Lookin' psychoti... erm... really good there foureasy, it's funny how sometimes lookin' at a pic will help spot details when the real bike is sittin' right there - I refer to pics of mine alla time with that same thought, and it really does help to pick out incongruities...

I dunno why, but it works FTW *shrug*