You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi from the UK - INDIAN Board Tracker tribute, my first build

- Thread starter PeteMcP

- Start date

PeteMcP

Well-Known Member

Ralph & Rick,

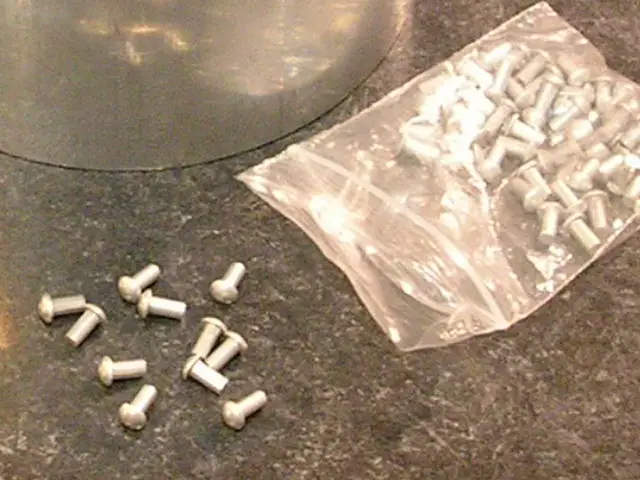

The Ali rivets used on my tank are really just a cosmetic addition. The pre-drilled tubular tank body and pair of domed ends were first 'brazed' together using Alubuild300 rods, after which the aluminium rivets were fixed in place using drops of fuel-proof POR15 - the same stuff I used to seal the inside of the entire tank. Once completed, two applications of POR15 sloshed inside the tank ensured the thing is thoroughly sealed. After the recommended 96 hours curing time, that stuff sets solid. You'd have to destroy the tank to remove the rivets.

Those aluminium rivets were sourced via eBay and are available in various shank diameters/lengths. Mine were 3mm x 6mm. The spun hemispherical ends of the tank were supported over an offcut of the tank's aluminium tube whilst being drilled with a 3mm bit. Then the tank ends were placed over the tank body and used as a locating jig for its holes. Tank bands are from 10mm x 2mm aluminium strip, formed to shape in my rolling bars, drilled, then riveted in place.

FYI, those rivets are not hollow-tailed. I never intended hammering them closed. Price was around 3 quid for a bag of 50.

The Ali rivets used on my tank are really just a cosmetic addition. The pre-drilled tubular tank body and pair of domed ends were first 'brazed' together using Alubuild300 rods, after which the aluminium rivets were fixed in place using drops of fuel-proof POR15 - the same stuff I used to seal the inside of the entire tank. Once completed, two applications of POR15 sloshed inside the tank ensured the thing is thoroughly sealed. After the recommended 96 hours curing time, that stuff sets solid. You'd have to destroy the tank to remove the rivets.

Those aluminium rivets were sourced via eBay and are available in various shank diameters/lengths. Mine were 3mm x 6mm. The spun hemispherical ends of the tank were supported over an offcut of the tank's aluminium tube whilst being drilled with a 3mm bit. Then the tank ends were placed over the tank body and used as a locating jig for its holes. Tank bands are from 10mm x 2mm aluminium strip, formed to shape in my rolling bars, drilled, then riveted in place.

FYI, those rivets are not hollow-tailed. I never intended hammering them closed. Price was around 3 quid for a bag of 50.

PeteMcP

Well-Known Member

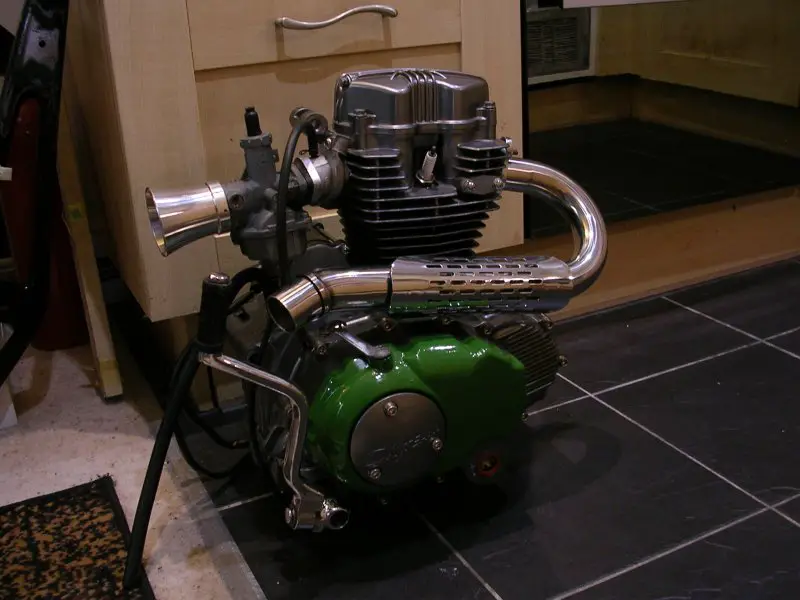

Bought the wheels/tyres for this build long before Christmas - and I've been fretting over whether or not they will look right when installed ever since then. Finally managed to get the tyres on the rims yesterday and now I can see the rear wheel/tyre combo in place in the frame I'm very pleased how things are looking. Will now need to source a rear mudguard.

With those new Honda CG125 18" drum-braked wheels front & rear means this steed will have no problem stopping.

Work now begins on shortening the girder fork legs so the bike sits level.

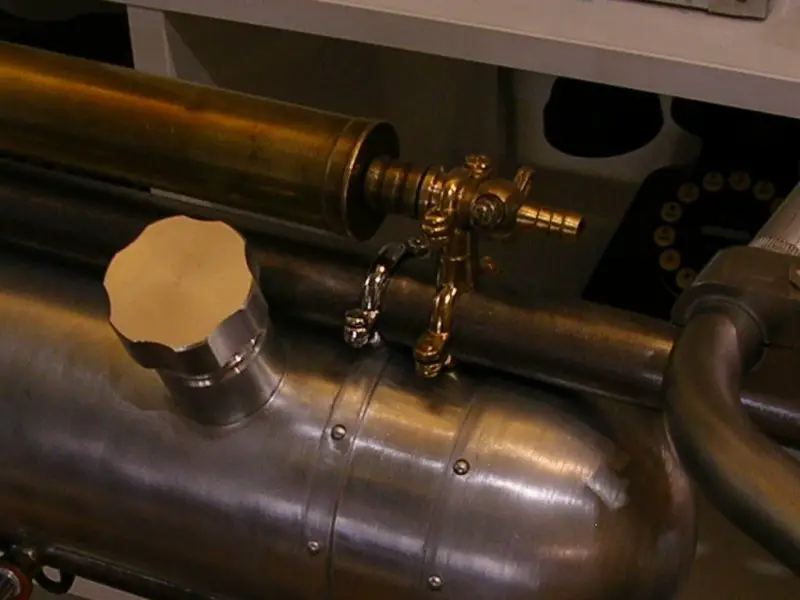

Few more little jobs sorted yesterday also, in between looking after Jen. Motor now sports it's heat shield and kickstart lever. And my penchant for various sized Munsen rings resulted in a neat means of securely mounting the vintage brass pump to the frame's top tube.

With those new Honda CG125 18" drum-braked wheels front & rear means this steed will have no problem stopping.

Work now begins on shortening the girder fork legs so the bike sits level.

Few more little jobs sorted yesterday also, in between looking after Jen. Motor now sports it's heat shield and kickstart lever. And my penchant for various sized Munsen rings resulted in a neat means of securely mounting the vintage brass pump to the frame's top tube.

PeteMcP

Well-Known Member

Thanks Rick,

The overall outside diameter of these tyres is what I was most concerned about looks-wise. Going with an 18x3.25" tyre at the rear gives a total o/d of 25" - just one inch short of a twenty six incher I'd normally run if using bicycle rims. The 18x3" tyre up front is just a half inch dia. less. So no worries there either.

A sorta-boardie vintage tribute build like this just wouldn't look right if under-tyred.

The overall outside diameter of these tyres is what I was most concerned about looks-wise. Going with an 18x3.25" tyre at the rear gives a total o/d of 25" - just one inch short of a twenty six incher I'd normally run if using bicycle rims. The 18x3" tyre up front is just a half inch dia. less. So no worries there either.

A sorta-boardie vintage tribute build like this just wouldn't look right if under-tyred.

PeteMcP

Well-Known Member

Busy mocking-up the front end to calculate how much I need to remove from the lower ends of those girder fork legs before creating the new front axle hole. That's tomorrow's workload scheduled.

Bike presently sits a fraction nose up - about an inch - due to the cast-on front mudguard bracket on the lower fork crossmember resting on top of the front tyre as shown in the last pic below. So that bracket will be the first thing to go.

Could really do with temporarily fitting the motor into the frame to see how much its weight affects compression of the girder fork spring prior to doing any measuring and cutting of the forks.

Man, I really miss having a proper garage space to work in and access to much of my tools and equipment which are currently in storage, but it's surprising what I've managed to achieve on this and two other recent builds in a very restricted 6ft x 6ft domestic kitchenette floor space and with little more than a very few hand tools.

Bike presently sits a fraction nose up - about an inch - due to the cast-on front mudguard bracket on the lower fork crossmember resting on top of the front tyre as shown in the last pic below. So that bracket will be the first thing to go.

Could really do with temporarily fitting the motor into the frame to see how much its weight affects compression of the girder fork spring prior to doing any measuring and cutting of the forks.

Man, I really miss having a proper garage space to work in and access to much of my tools and equipment which are currently in storage, but it's surprising what I've managed to achieve on this and two other recent builds in a very restricted 6ft x 6ft domestic kitchenette floor space and with little more than a very few hand tools.

Tom from Rubicon

Well-Known Member

Lovely place to locate a mudguard bracket! Break out the bloody plasma torch, Might get the neighbors talking.

May I ask Pete, how is Jen getting on?

Doc's here have Mona's cancer stopped for now. We see the Oncologist week after next.

Tom

May I ask Pete, how is Jen getting on?

Doc's here have Mona's cancer stopped for now. We see the Oncologist week after next.

Tom

PeteMcP

Well-Known Member

Plasma torch, Tom? More like a junior hacksaw, file, and plenty elbow grease!

Glad to hear Mona's making progress. My brother-in-Law Keith was discharged from hospital two weeks ago after having an op to remove a third of his liver and three tumors. A scan and tests on Thursday gave him the all clear for now too.

Jen's hit another flat spot, appetite wise, for more than a week now. Proper mealtimes are non-existent, so trying to get her to accept little morsels of whatever, umpteen times a day, is the only way to go. Good days and bad days - with more of the latter. Despite my best efforts, trying to maintain her weight is a constant struggle. I'm also concerned that for the last 10 days she's taken to blankly staring downward all day. Google says this is common amongst dementia sufferers - but it's disconcerting for carers none the less.

.

Glad to hear Mona's making progress. My brother-in-Law Keith was discharged from hospital two weeks ago after having an op to remove a third of his liver and three tumors. A scan and tests on Thursday gave him the all clear for now too.

Jen's hit another flat spot, appetite wise, for more than a week now. Proper mealtimes are non-existent, so trying to get her to accept little morsels of whatever, umpteen times a day, is the only way to go. Good days and bad days - with more of the latter. Despite my best efforts, trying to maintain her weight is a constant struggle. I'm also concerned that for the last 10 days she's taken to blankly staring downward all day. Google says this is common amongst dementia sufferers - but it's disconcerting for carers none the less.

.

Tom from Rubicon

Well-Known Member

Plasma torch, Tom? More like a junior hacksaw, file, and plenty elbow grease!

My tendonitis is flaring up just in the thinking. Best I keep me trap shut. Carry on Sir.

My tendonitis is flaring up just in the thinking. Best I keep me trap shut. Carry on Sir.

PeteMcP

Well-Known Member

Fork shortening should be a straightforward op Rick. Always knew I'd have to go there using these forks on this build. That time has come.

Fist up, I'm sticking with the bike's 1" nose up attitude as it presently sits. With the engine temporarily mounted and me sat aboard earlier today, the girder fork spring compressed about 3/4", so by my reckoning, that gets us near enough sitting level. Take a tank-full of gas into account and I reckon it'll be cock-on.

Forks now dismantled and marked for drilling the new axle hole. Pics show the pair of (thankfully dead straight and unmolested) fork legs securely bolted together ready for drilling. I've arrowed where the new axle holes will be located - a whole 2-3/4" higher up the fork legs. New wheel has a 12mm axle - so I'll be making axle HOLES, not SLOTS. Once cut, the lower fork ends will be shaped as per the originals, not just a straight cut.

The shiny area where I've ground away the black powder coating back to bare metal is where I had to grind off a welded-on domed rivet head which was welded to a tubular steel stub inside the RIGHT fork leg. This stub would have slotted into the drum brake plate on whatever bike these forks were originally paired with. However, the Honda CG 18" drum-braked wheel on this build has the brake plate/lever and, oh yes!, integrated speedo drive located on the opposite side so I'll need to weld a stub to the inside of the LEFT fork leg.

I've already removed the cast-on mudguard bracket from the lower fork crossmember (shown in the last pic of post 727 above) which will leave a comfortable one inch clearance between tyre and crossmember when using the new axle location..

Fist up, I'm sticking with the bike's 1" nose up attitude as it presently sits. With the engine temporarily mounted and me sat aboard earlier today, the girder fork spring compressed about 3/4", so by my reckoning, that gets us near enough sitting level. Take a tank-full of gas into account and I reckon it'll be cock-on.

Forks now dismantled and marked for drilling the new axle hole. Pics show the pair of (thankfully dead straight and unmolested) fork legs securely bolted together ready for drilling. I've arrowed where the new axle holes will be located - a whole 2-3/4" higher up the fork legs. New wheel has a 12mm axle - so I'll be making axle HOLES, not SLOTS. Once cut, the lower fork ends will be shaped as per the originals, not just a straight cut.

The shiny area where I've ground away the black powder coating back to bare metal is where I had to grind off a welded-on domed rivet head which was welded to a tubular steel stub inside the RIGHT fork leg. This stub would have slotted into the drum brake plate on whatever bike these forks were originally paired with. However, the Honda CG 18" drum-braked wheel on this build has the brake plate/lever and, oh yes!, integrated speedo drive located on the opposite side so I'll need to weld a stub to the inside of the LEFT fork leg.

I've already removed the cast-on mudguard bracket from the lower fork crossmember (shown in the last pic of post 727 above) which will leave a comfortable one inch clearance between tyre and crossmember when using the new axle location..

PeteMcP

Well-Known Member

Begun the fork shortening process by first concentrating on the left fork leg. Right fork leg is just a straightforward cut thanks to the plain wheel hub on that side. Left side however required some thought how best to modify the fork leg to clear the Honda brake plate's cast-on speedo housing. Plus, I needed to fasten some kind of stub inside the fork leg which engaged into the cast-on slot in the brake plate. Pics show the left fork leg shortened by 2-3/4", and the half-moon slot (arrowed) filed into the fork leg to clear the speedo housing. New 12mm axle hole was drilled and also a pair of 8mm holes to accept a pair of threaded M8 hex connectors which perfectly engage into the cast-on slot in the brake plate.

Have to mention these new Honda CG125 drum-braked wheels I'm using on this build. First time I've used proper motorcycle wheels on a build and I have to say at £60 for the front wheel, you certainly get a lot for your money. Just have to replace the standard 210mm axle with a shorter 140mm long one on account of using vintage girder forks. Ordered one from eBay earlier today.

Have to mention these new Honda CG125 drum-braked wheels I'm using on this build. First time I've used proper motorcycle wheels on a build and I have to say at £60 for the front wheel, you certainly get a lot for your money. Just have to replace the standard 210mm axle with a shorter 140mm long one on account of using vintage girder forks. Ordered one from eBay earlier today.

Oldbiscuit

Well-Known Member

Pete, that is going to be one sweet bike, actually it already is ! Me personally, I’d leave the forks black with silver accents. I can’t wait to see it once it’s completed.

Tom from Rubicon

Well-Known Member

Following OB's thought and having seen your artistry. Minimalist pin striping silver on black. Honest to God Pete one never suspect you altered the forks. Like the say in California, Primo!

Tom

Tom

I was looking at the forks when you said they needed cutting down and all I could think of is where do you start. Nothing is straight so you can easily establish a center line and unless you can clamp them together and drill a pilot through them both at the same time you have to do it twice.

Tom is right. No one would suspect that you had altered the forks in anyway.

Steve.

Tom is right. No one would suspect that you had altered the forks in anyway.

Steve.

Tom from Rubicon

Well-Known Member

There is your benediction Pete, Steve's benediction of mine stands. What other marvels will you awe us with?

Make it a surprise.

Tom

Make it a surprise.

Tom

PeteMcP

Well-Known Member

Thanks guys.

Fork shortening was actually pretty simple. Made even more so by my purchase of a Powerfile which made the final shaping of the lower fork ends so much quicker. As someone used to laboriously hand-filing metal, I now wonder how/why I didn't buy a Powerfile years ago. Hardest thing about the entire process was wiping down everything in the kitchen to remove the coating of fine iron filings!

Design of these fork legs made establishing a centreline a cinch Steve. Plenty holes in them to use as reference points. Bolting the stamped metal legs together so they could be drilled in one go ensured everything lined up. And the fact there was sufficient solid metal at the lower ends of the fork legs, post shortening, to both accommodate the new axle hole and the brake plate stub means I don't have to worry about having weakened anything.

Fork shortening was actually pretty simple. Made even more so by my purchase of a Powerfile which made the final shaping of the lower fork ends so much quicker. As someone used to laboriously hand-filing metal, I now wonder how/why I didn't buy a Powerfile years ago. Hardest thing about the entire process was wiping down everything in the kitchen to remove the coating of fine iron filings!

Design of these fork legs made establishing a centreline a cinch Steve. Plenty holes in them to use as reference points. Bolting the stamped metal legs together so they could be drilled in one go ensured everything lined up. And the fact there was sufficient solid metal at the lower ends of the fork legs, post shortening, to both accommodate the new axle hole and the brake plate stub means I don't have to worry about having weakened anything.