You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi from the UK - INDIAN Board Tracker tribute, my first build

- Thread starter PeteMcP

- Start date

Oldbiscuit

Well-Known Member

Same to you Pete !HAPPY NEW YEAR folks!

Here's wishing everyone all the best for 2021.

indian22

Well-Known Member

Pete best to you as well and to all our amigos participating on the forum. I want you all to know that the forum conversations have been a bright spot in a year which has been very difficult for many, yet I've experienced wonderful positives during 2020 as well

I'm looking forward to being a better man in 21and beyond.

Rick C.

I'm looking forward to being a better man in 21and beyond.

Rick C.

Tom from Rubicon

Well-Known Member

Best to you Pete, in 2021.

Tom

Tom

PeteMcP

Well-Known Member

Making slow progress on the forks for the latest build.

After purchasing a cool set of vintage girder forks for the latest build, I've since incurred the extra expense of buying 4 x links and 4 x spindles needed to complete them.

Steerer tube needed threading further AND fork legs need shortning, so REALLY beginning to think I should have just gone and purchased a set of Ruff Regulator sprung girder forks which would have saved me a lot of time and, yes, money, instead of adapting the unidentified vintage motor(auto)cycle girder forks I'm using.

Finally mated the fork's steer tube to the frame's (adapted) headtube after a spell of time/money wasting. Problem was, only the top 3/4" of the steer tube was threaded, and I needed to purchase an appropriate die to extend the threads 1" further down the tube. Most of my tools are still in storage - including my thread gauge - so I resorted to counting the threads per inch on the fork steer tube (difficult when only 3/4" of the steerer was threaded) then searched eBay for the die I thought I needed. (None of my local bike shops could offer a steerer tube threading service these days).

I should point out I did some on-line searches to help determine which thread size I might be after - and that there were 3 x sizes of 1" dia. steer tube threads to choose from - 24tpi, 25.4tpi and 26tpi. I reckoned 24tpi was what I needed, so I ordered the appropriate die from a China seller, the only place on eBay listing these at an affordable price (for a tool I'll probably only ever use ONCE).

Couple of weeks later, the die arrived - along with a suitable 55mm dia. die holder from a UK eBay seller - and lo and behold its threads didn't match those on the fork steer tube. Looked like I needed a 1" diameter 26tpi die instead. As luck would have it, I found a UK seller on eBay who was offering these for a 'Best Offer' price, so I scored one for under 20 quid - way less than the 50-80 quid some sellers were asking. Die showed up a few days later and it was the correct thread size - but the die was slightly too large a diameter to fit the die holder I just bought!

I jerry-rigged a solution by gripping the die in a machine vice and by slowly hand turning and backing-off the well-lubed steer tube I was able to extend the threaded portion 1" further down the tube. Sorted.

Now I can begin to calculate how much material I need to cut from the lower fork leg girders prior to relocating the axle holes for the front wheel...

After purchasing a cool set of vintage girder forks for the latest build, I've since incurred the extra expense of buying 4 x links and 4 x spindles needed to complete them.

Steerer tube needed threading further AND fork legs need shortning, so REALLY beginning to think I should have just gone and purchased a set of Ruff Regulator sprung girder forks which would have saved me a lot of time and, yes, money, instead of adapting the unidentified vintage motor(auto)cycle girder forks I'm using.

Finally mated the fork's steer tube to the frame's (adapted) headtube after a spell of time/money wasting. Problem was, only the top 3/4" of the steer tube was threaded, and I needed to purchase an appropriate die to extend the threads 1" further down the tube. Most of my tools are still in storage - including my thread gauge - so I resorted to counting the threads per inch on the fork steer tube (difficult when only 3/4" of the steerer was threaded) then searched eBay for the die I thought I needed. (None of my local bike shops could offer a steerer tube threading service these days).

I should point out I did some on-line searches to help determine which thread size I might be after - and that there were 3 x sizes of 1" dia. steer tube threads to choose from - 24tpi, 25.4tpi and 26tpi. I reckoned 24tpi was what I needed, so I ordered the appropriate die from a China seller, the only place on eBay listing these at an affordable price (for a tool I'll probably only ever use ONCE).

Couple of weeks later, the die arrived - along with a suitable 55mm dia. die holder from a UK eBay seller - and lo and behold its threads didn't match those on the fork steer tube. Looked like I needed a 1" diameter 26tpi die instead. As luck would have it, I found a UK seller on eBay who was offering these for a 'Best Offer' price, so I scored one for under 20 quid - way less than the 50-80 quid some sellers were asking. Die showed up a few days later and it was the correct thread size - but the die was slightly too large a diameter to fit the die holder I just bought!

I jerry-rigged a solution by gripping the die in a machine vice and by slowly hand turning and backing-off the well-lubed steer tube I was able to extend the threaded portion 1" further down the tube. Sorted.

Now I can begin to calculate how much material I need to cut from the lower fork leg girders prior to relocating the axle holes for the front wheel...

Tom from Rubicon

Well-Known Member

Well Pete, I hope you can resell the dies and die stock and recover some of these expenses.

Tom

Tom

indian22

Well-Known Member

Lol is way overused but I'll risk it as I couldn't help myself from laughing as I read just how forked you were on the current build. The last fork I made was the leaf spring for my Simplex I did so only after searching far and wide for a complete leaf fork & the ones available would have needed major changes to actually work. Then there was cost a thousand U.S. was bargain basement and looked horrible and the ones costing thousands would also require major alterations. All built for large motorcycles, mostly Harley. So I built my own and I'd do it again, and there is a high probability of that occurring. It wasn't exactly an inexpensive solution either.

I know your having fun with it and solving problems helps us feel a bit useful!

Rick C.

I know your having fun with it and solving problems helps us feel a bit useful!

Rick C.

Pete,

I have the same thing going on. I'm making up a parts list and I need to thread a steering tube for the electric tri car. It's a long one and needs to be threaded on each end. The die and holder are about $125 Canadian from China. Use it once and it goes up on the shelf most likely never to be used again.

I have a fairly substantial collection of tools and parts like that.

Steve.

I have the same thing going on. I'm making up a parts list and I need to thread a steering tube for the electric tri car. It's a long one and needs to be threaded on each end. The die and holder are about $125 Canadian from China. Use it once and it goes up on the shelf most likely never to be used again.

I have a fairly substantial collection of tools and parts like that.

Steve.

PeteMcP

Well-Known Member

Same here, Steve.

I might have just the die you're looking for. I have 1" dia, cycle steer tube dies with 24 and 26 tpi. Let's get some kind of small tool collective going. I'm happy to 'pass it on' when it comes to infrequently used - often single use - tools.

Air mailing either of these dies to Canada no probs.

I might have just the die you're looking for. I have 1" dia, cycle steer tube dies with 24 and 26 tpi. Let's get some kind of small tool collective going. I'm happy to 'pass it on' when it comes to infrequently used - often single use - tools.

Air mailing either of these dies to Canada no probs.

Hi Pete,

Thank you. I'll send you a message when the time comes but it will be a while. It's 32F at the moment and sunny but we're in for a couple of weeks of cold weather and snow they say so the old boy will be hibernating until it's over. We have another 5 weeks of winter before it starts to warm up.

Meanwhile, back to my parts list. Good time to get everything delivered while I wait the weather out.

Steve.

Thank you. I'll send you a message when the time comes but it will be a while. It's 32F at the moment and sunny but we're in for a couple of weeks of cold weather and snow they say so the old boy will be hibernating until it's over. We have another 5 weeks of winter before it starts to warm up.

Meanwhile, back to my parts list. Good time to get everything delivered while I wait the weather out.

Steve.

PeteMcP

Well-Known Member

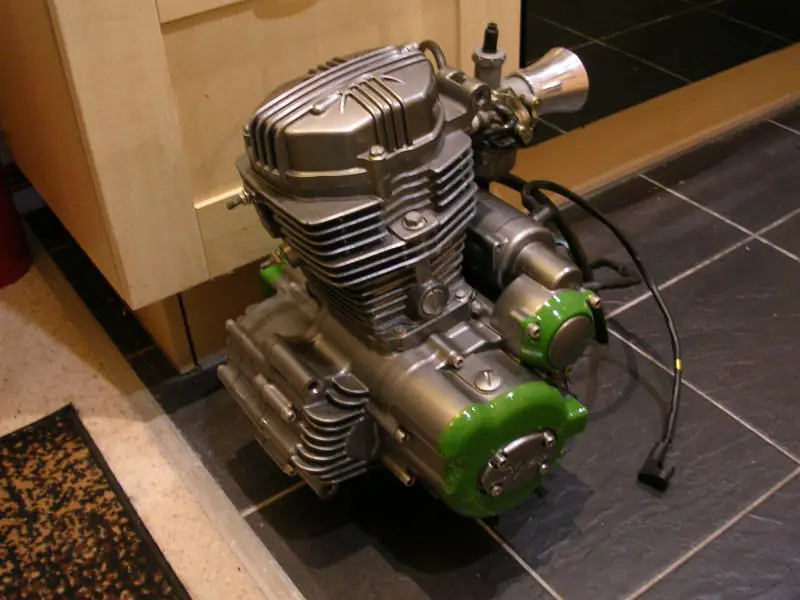

Been doing a little tarting-up of the motor for my latest build. Replaced many of the zinc plated bolts with stainless allen cap heads. Hoping that painting some areas of the motor casings will help back-date the look of the somewhat modern-looking Skyteam 125.

No going back now - that RAL Brilliant Green I went with on the motor has decided the bike's colour!

Next job on the motor is to paint the lower half of the cylinder barrel VHT satin black.

No going back now - that RAL Brilliant Green I went with on the motor has decided the bike's colour!

Next job on the motor is to paint the lower half of the cylinder barrel VHT satin black.

PeteMcP

Well-Known Member

Thanks.

That stainless tank on my first build, the Indian BTR tribute, is a commercially available item. I purchased the tank, frame and springer forks from cnolmotorsport in China via eBay. Other sellers in the US occasionally retail the tank/frame.

Can confirm I just recently noticed the tank for sale on AliExpress.

That stainless tank on my first build, the Indian BTR tribute, is a commercially available item. I purchased the tank, frame and springer forks from cnolmotorsport in China via eBay. Other sellers in the US occasionally retail the tank/frame.

Can confirm I just recently noticed the tank for sale on AliExpress.

PeteMcP

Well-Known Member

HAPPY EASTER FOLKS!

After many months of waiting patiently, the pair of spun aluminium hemispheres I ordered from a local metal spinning company showed up midweek. To be fair, I told them I was in no hurry. Just pleased to find a company prepared to go to the trouble of spinning only TWO bespoke items to my specs. A job like that was never going to be near the top of their workload schedule.

The domed ends were spun over a custom-fabbed steel former - which naturally added greatly to the cost. But that's something I was prepared for to get what I wanted. They quoted me pricing for 20 x sets which would have dramatically reduced the cost - but what would I do with 19 spare sets of tank ends?

Anyhow, I'm extremely happy how these spun aluminium parts turned out. I've attached some pics here showing may latest build's tank under construction and hopefully folks agree the tank is shaping up nicely. Has more than a bit of a Steampunk look about it - especially with the brass oil pump and aluminium rivets.

Also fabbed parts for the bike's rear drum brake torque arm using high tensile threaded rod clad in stainless tube and topped off with rod end bearings. The stainless steel mount for the torque arm can now be silver soldered to the lower frame stay.

Bought a vintage set of steel handlebar mounts for the girder forks I'm going with on this build - but as usual, the holes in these fitted neither the 7/8" bars or the 3/4" fork crossmember. Made a set of 7/8" to 1" shims for the bars and turned down the ends of the fork crossmember so everything fits as shown in the pics. Those bars are the originals from my Honda Solo; inverted on this current build, they look the part but I can't see myself being comfy with them. May yet go with a set of vintage pull back bars to give a more upright ride in conjuction with the vintage Dutch Lepper Primus saddle I'm using. Bought new, but gently distressed the leather to suit the vibe of this build.

After many months of waiting patiently, the pair of spun aluminium hemispheres I ordered from a local metal spinning company showed up midweek. To be fair, I told them I was in no hurry. Just pleased to find a company prepared to go to the trouble of spinning only TWO bespoke items to my specs. A job like that was never going to be near the top of their workload schedule.

The domed ends were spun over a custom-fabbed steel former - which naturally added greatly to the cost. But that's something I was prepared for to get what I wanted. They quoted me pricing for 20 x sets which would have dramatically reduced the cost - but what would I do with 19 spare sets of tank ends?

Anyhow, I'm extremely happy how these spun aluminium parts turned out. I've attached some pics here showing may latest build's tank under construction and hopefully folks agree the tank is shaping up nicely. Has more than a bit of a Steampunk look about it - especially with the brass oil pump and aluminium rivets.

Also fabbed parts for the bike's rear drum brake torque arm using high tensile threaded rod clad in stainless tube and topped off with rod end bearings. The stainless steel mount for the torque arm can now be silver soldered to the lower frame stay.

Bought a vintage set of steel handlebar mounts for the girder forks I'm going with on this build - but as usual, the holes in these fitted neither the 7/8" bars or the 3/4" fork crossmember. Made a set of 7/8" to 1" shims for the bars and turned down the ends of the fork crossmember so everything fits as shown in the pics. Those bars are the originals from my Honda Solo; inverted on this current build, they look the part but I can't see myself being comfy with them. May yet go with a set of vintage pull back bars to give a more upright ride in conjuction with the vintage Dutch Lepper Primus saddle I'm using. Bought new, but gently distressed the leather to suit the vibe of this build.

Tom from Rubicon

Well-Known Member

Well ya done it Pete, I'm gobsmacked again.

Tom

Tom