You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Old Guys Simplex moto-peddle bike

- Thread starter indian22

- Start date

Tom from Rubicon

Well-Known Member

What Steve said + will be interesting to see the bags mounted.

Non local Hummers are here already. Way ahead of time by my watch.

Tom

Non local Hummers are here already. Way ahead of time by my watch.

Tom

indian22

Well-Known Member

Hi Steve and thanks. They are actually long enough for a 48 v too. Almost deep enough for two 20 amp hour 36v. The saddle on the Schwinn is a really dark chocolate.Rick, those bags are first rate. Great colour and thick leather. Size looks to just right.

Steve.

The tool bag was really wadded up but will pop into shape with a bit of filler and time.

Rick C.

indian22

Well-Known Member

What Steve said + will be interesting to see the bags mounted.

Non local Hummers are here already. Way ahead of time by my watch.

Tom

Tom this Summer has been an odd one so the bird behavior is probably a coping method. I donno?

I build a small steel shelf under the bags and this loops over the rack and bolts onto the rack top. This keeps the bags level and fully supported from below with no strain on the straps or bags. One bag can be empty and the other fully loaded and both appear the same. I also line the bags bottom with a thick piece of bed liner rubber to really insulate the battery pack.

Rick C.

indian22

Well-Known Member

Long day guys but a good one.

I mounted the rear with some shop built brackets. Repositioned the saddle several times with the help of more shop made parts. And fabricated the steel saddlebag support I described in a previous post and then mounted the bags with only one battery used. This went really well because I've done this saddlebag battery support twice before on other bikes. I reinforced and isolated both bags with 3/8" thick bed liner mat. To protect both battery and bags. This is how I spent my day having fun.

Tomorrow it's tackle the chains day as I mount the primary chain for the first time and attempt to get all three working with each other. All line up well but getting the proper tension on all three can be a task. I have master links and halfinks I can use on the 415 chain driving the primary and secondary if required, but haven't found them for the KMC 1/8" pedal chain.

Rick C.

I mounted the rear with some shop built brackets. Repositioned the saddle several times with the help of more shop made parts. And fabricated the steel saddlebag support I described in a previous post and then mounted the bags with only one battery used. This went really well because I've done this saddlebag battery support twice before on other bikes. I reinforced and isolated both bags with 3/8" thick bed liner mat. To protect both battery and bags. This is how I spent my day having fun.

Tomorrow it's tackle the chains day as I mount the primary chain for the first time and attempt to get all three working with each other. All line up well but getting the proper tension on all three can be a task. I have master links and halfinks I can use on the 415 chain driving the primary and secondary if required, but haven't found them for the KMC 1/8" pedal chain.

Rick C.

indian22

Well-Known Member

Pedal chain is too short so I'll concentrate on the two motor drive chains first.

Basic wiring should be simple, final placement of controller close to the motor for short leads. High amps. On/off switch location? No lock. Battery leads will be fine.

I may run a separate instrument battery for lights etc. Small low voltage high capacity lithium pack in the fuel tank with charge port under the gas cap.

Motor needs side plate on the pedal side and cosmetic touches added later. Thumb throttle should arrive today. That will go on the left bar.

Front disc lever mounts on right side of bar. Coaster rear. I came real close last night to swapping in a Sturmey front drum but with the coaster I need some stopping power. The motor brake on these is like jamming a gas bike in low for compression braking. Regen for electrical generation is to me a joke but the actual motor braking generated is impressive on these scooter motors and way offset the limitations of a coaster brake when running mid motor setup not sharing a pedal chain.

Rick C.

Basic wiring should be simple, final placement of controller close to the motor for short leads. High amps. On/off switch location? No lock. Battery leads will be fine.

I may run a separate instrument battery for lights etc. Small low voltage high capacity lithium pack in the fuel tank with charge port under the gas cap.

Motor needs side plate on the pedal side and cosmetic touches added later. Thumb throttle should arrive today. That will go on the left bar.

Front disc lever mounts on right side of bar. Coaster rear. I came real close last night to swapping in a Sturmey front drum but with the coaster I need some stopping power. The motor brake on these is like jamming a gas bike in low for compression braking. Regen for electrical generation is to me a joke but the actual motor braking generated is impressive on these scooter motors and way offset the limitations of a coaster brake when running mid motor setup not sharing a pedal chain.

Rick C.

Tom from Rubicon

Well-Known Member

indian22

Well-Known Member

Well a steady diet of chains and sprockets the last two days had me working on tensioners in my sleep last night and all morning as well. Final solution? Yet to be determined, but it does keep me on shedule, kind of, for a ride this weekend. Rain expected and needed tomorrow all day. Might push the ride a day.

As she sat before lunch.

Rick C.

As she sat before lunch.

Rick C.

indian22

Well-Known Member

Moving the Schwinn back inside for wirimg and first tests using power supply.and kitchen table for a work bench.

Once the Schwinn's rideable. I plan on a controller swap for the Ol' Crow. I just don't have confidence in the controller. I think my shorting it damaged it though it works to a degree I expect it to fail at any time.

Rick C.

Once the Schwinn's rideable. I plan on a controller swap for the Ol' Crow. I just don't have confidence in the controller. I think my shorting it damaged it though it works to a degree I expect it to fail at any time.

Rick C.

Tom from Rubicon

Well-Known Member

That is one sexy drive tensioner Rick! Is it yours or a commercial product?

Tom

Tom

indian22

Well-Known Member

Part mine and part commercial, Tom. I hurried this one so as to get a working drive train going. I will go back and machine the clamp plates with a channel for the frame tube. As is it's just two flats against the round tube. This one needs to be .75" deeper to get the torsion spring to function optimally. I have a small 1/2" pitch roller bearing sprocket that I can use in place of the nylon roller, if I can locate it. Also I plan to bolt through the plates with grade 8 hardware as I pulled thread getting these to hold. So this is in effect a prototype and a non functional concept as shown, but does look good. Another couple of hours on the mill should complete it. I'm running short on half inch 6061 plate so don't want to screw up and have to wait a week for delivery.

Thanks for the compliment brother.

The pedal chain tensioner is a slightly altered kit type that serves a purpose for now but I will fab a billet aluminum replacement which is less vertical to match the other side only smaller. A guy doesn't want a tensioner that can swivel into the spokes.

The reduction drive works fine with 415 chain but rubs when a half link is used. So that's a clearance job for the lathe. Also the chain is really close to rubbing on the drive off stands spring catches. On the Ol' Crow I welded tabs on the pedal side and moved the two springs, but that would be overkill to correct this potential rub.

Part of the problem with showing progress photos is that it infers success, as in completion, and this is so often not the case for my work. I have at least a half dozen corrections to make on my work to this point on the Schwinn. None of which are difficult, but all are important to having a safe and functional build.

Tensioners are dangerous if not designed and installed properly and maintained carefully, but so are so many components used to construct a decent bicycle let alone a motorized one.

Rick C.

Thanks for the compliment brother.

The pedal chain tensioner is a slightly altered kit type that serves a purpose for now but I will fab a billet aluminum replacement which is less vertical to match the other side only smaller. A guy doesn't want a tensioner that can swivel into the spokes.

The reduction drive works fine with 415 chain but rubs when a half link is used. So that's a clearance job for the lathe. Also the chain is really close to rubbing on the drive off stands spring catches. On the Ol' Crow I welded tabs on the pedal side and moved the two springs, but that would be overkill to correct this potential rub.

Part of the problem with showing progress photos is that it infers success, as in completion, and this is so often not the case for my work. I have at least a half dozen corrections to make on my work to this point on the Schwinn. None of which are difficult, but all are important to having a safe and functional build.

Tensioners are dangerous if not designed and installed properly and maintained carefully, but so are so many components used to construct a decent bicycle let alone a motorized one.

Rick C.

MEASURE TWICE

Well-Known Member

I know since LiPo batteries I used a long time ago that there are protective circuits attached to the battery output before the terminals go to the load you attach. Probably all newer lithium type batteries have this as part of the pack. In the past, I was adding one of these protection circuits myself to a LiPo cell that would power a step up inverter voltage circuit. Wanted 9vdc from the 4.2vdc for a camera supply. What I had not figured in was the addition amperage which is needed to do the conversion. Even though I think I did not short the output of the protection circuit, I must have overloaded it. I probably needed one with more amperage specified.Moving the Schwinn back inside for wirimg and first tests using power supply.and kitchen table for a work bench.

Once the Schwinn's rideable. I plan on a controller swap for the Ol' Crow. I just don't have confidence in the controller. I think my shorting it damaged it though it works to a degree I expect it to fail at any time.

Rick C.

Just wondering if there are protection circuits made specific to the output of these motor controllers? I don't know if they exist or come built in on some motor controllers?

As for riding my offroad bike this time of year, no way. The area I go to inland is way too hot now. Insurance for another year paid, but think maybe wait till October an after.

indian22

Well-Known Member

Good question MT.

As both voltages and current are both high in the battery packs used for motorizing all types of transport, circut protection is a fundamental priority with good designers.

Both the battery and controller have built in circut protection. The battery circut is called a BMS (Battery Management System) and has several levels of overcharge, undercharge, overheating etc. functions. The controller depending on the sophistication of the circut firmware and software programmable by the user in some controllers, have overlapping functions plus unique motor control features for safety and higher performance which isn't just a speed and torque thing, but also a range and optimal settings for system life of all components motor, battery and controller.

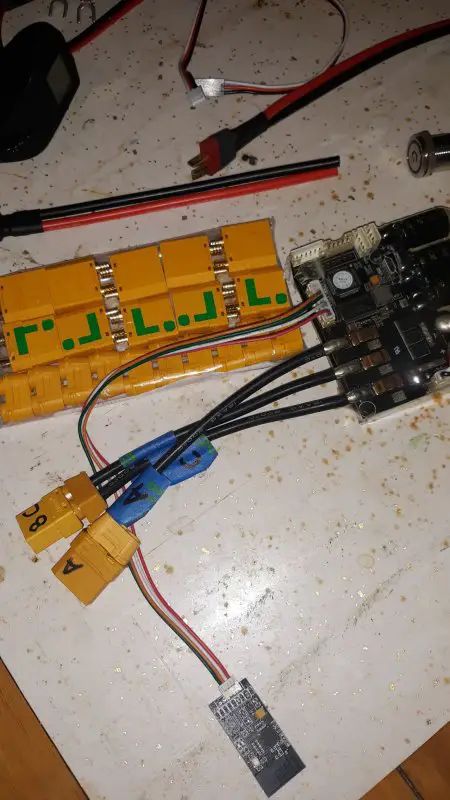

Two things I add are an on off switch and reistor power connectors "Anti spark" connectors at the battery disconnect point. These prevent that very large amperage from melting the plug contacts on reconnection to the system. Photo below of the XT 90 connectors. The package of five with the green L on the side are anti spark other than the L they look the same as the regular XT 90 shown connecting the phase wires to the motor.

The anti spark connentor goes between battery pack piwer out and controller power input leads.

Also a fuse in circut between the battery and other components is prudent as well for those (like me) who on occassion short a system out.

Lithium is a catchall term for some very deverse battery chemistries which while related have very different properties in actual use. Some are designed for really high discharge, some are mid road, others allow for many more cycles of charging and some for greater safety (fire).

All this is pretty confusing and there is a good deal of learning involved, but that's still the case with internal combustion engines. I like both but still feel more confident around gas engines by far.

Hope some of this helps MT.

Rick C.

As both voltages and current are both high in the battery packs used for motorizing all types of transport, circut protection is a fundamental priority with good designers.

Both the battery and controller have built in circut protection. The battery circut is called a BMS (Battery Management System) and has several levels of overcharge, undercharge, overheating etc. functions. The controller depending on the sophistication of the circut firmware and software programmable by the user in some controllers, have overlapping functions plus unique motor control features for safety and higher performance which isn't just a speed and torque thing, but also a range and optimal settings for system life of all components motor, battery and controller.

Two things I add are an on off switch and reistor power connectors "Anti spark" connectors at the battery disconnect point. These prevent that very large amperage from melting the plug contacts on reconnection to the system. Photo below of the XT 90 connectors. The package of five with the green L on the side are anti spark other than the L they look the same as the regular XT 90 shown connecting the phase wires to the motor.

The anti spark connentor goes between battery pack piwer out and controller power input leads.

Also a fuse in circut between the battery and other components is prudent as well for those (like me) who on occassion short a system out.

Lithium is a catchall term for some very deverse battery chemistries which while related have very different properties in actual use. Some are designed for really high discharge, some are mid road, others allow for many more cycles of charging and some for greater safety (fire).

All this is pretty confusing and there is a good deal of learning involved, but that's still the case with internal combustion engines. I like both but still feel more confident around gas engines by far.

Hope some of this helps MT.

Rick C.

indian22

Well-Known Member

Time to run some wiring and solder plugs.

I took the.Excelsior Schwinn for a pedal ride and it seems to function with all three chains in place.

I did modify the spring tensioner and slightly modified it's dimensions and repositioned it on the frame. I channeled the two plates a bit to help prevent the tensioner canting into the spokes. I didn't have the torsion spring I needed to fab a spring loaded arm for the pedal chain, but did find a fixee spring arm I can make work with a little effort. The fixed tensioner can't get into the spokes as it has a frame bracket wedged between the two plates of the tensioner. A 24" pipe wrench couldn't move it! I just like spring tensioners.

Rick C.

This is about as good a drive train as I can build.

Tom I had to redo the plates and used grade 8 thru bolts rather than thread the back plate. The back plate is just a little to thin to take enough thread.

I took the.Excelsior Schwinn for a pedal ride and it seems to function with all three chains in place.

I did modify the spring tensioner and slightly modified it's dimensions and repositioned it on the frame. I channeled the two plates a bit to help prevent the tensioner canting into the spokes. I didn't have the torsion spring I needed to fab a spring loaded arm for the pedal chain, but did find a fixee spring arm I can make work with a little effort. The fixed tensioner can't get into the spokes as it has a frame bracket wedged between the two plates of the tensioner. A 24" pipe wrench couldn't move it! I just like spring tensioners.

Rick C.

This is about as good a drive train as I can build.

Tom I had to redo the plates and used grade 8 thru bolts rather than thread the back plate. The back plate is just a little to thin to take enough thread.

Last edited:

Tom from Rubicon

Well-Known Member

Going forward is easy, backing up and not having the chains walk off is the proof.

Keep having fun.

Tom

Keep having fun.

Tom

indian22

Well-Known Member

Tom I agree completely & spent some time backing round in circles mid day.

The pedal chain is not as tight as I like as it has an inch up or down. I can correct but will live with it till I fab a spring load tensioner mounted off the rear axle plate. I need a pretty strong torsion spring for it to work that far back with 1/8" chain.

I may add a small sprocket to the primary chain as well. More like an idler sprocket than as a tensioner.

Using a cartridge style bottom bracket for the basis of a jack shaft for the reduction sprockets seems a success on this frame.

Rick C

The pedal chain is not as tight as I like as it has an inch up or down. I can correct but will live with it till I fab a spring load tensioner mounted off the rear axle plate. I need a pretty strong torsion spring for it to work that far back with 1/8" chain.

I may add a small sprocket to the primary chain as well. More like an idler sprocket than as a tensioner.

Using a cartridge style bottom bracket for the basis of a jack shaft for the reduction sprockets seems a success on this frame.

Rick C

indian22

Well-Known Member

Next big project is a 36v, 48v and 72 volt all for the Ol' Crow using two 36v and one 48v. All 20 amp hr. batteries. With one controller and running the two 36v. In series for 72v. or run 36v at a time.

48v in the fuel tank and everything else in the saddlebags. Not a heavy battery load either.

I have the multi volt controller and a 72v motor in hand and only need purchase one additional 36v pack.

Each battery would be charged and balanced separately. 60 amp hour total.

Rick C.

48v in the fuel tank and everything else in the saddlebags. Not a heavy battery load either.

I have the multi volt controller and a 72v motor in hand and only need purchase one additional 36v pack.

Each battery would be charged and balanced separately. 60 amp hour total.

Rick C.

sportscarpat

Bonneville Bomber the Salt Flat record breaker

Are you running a half link on either side chains? Maybe you covered that already as I was only looking at the pictures. I like to adjust motor side first, no idler, then use 1/2 links or sprocket size to get the less important pedal side adjusted.

indian22

Well-Known Member

Hi Pat yes I'm running a half link on the motor side but didn't have or couldn't find a pedal side half link so i ordered a few. I want to get in a test ride

today. As basic wiring is complete.

Thanks for the tip on pedal side sprockets and order of chain adjustment.

Hope you guys are doing well.

Rick C.

today. As basic wiring is complete.

Thanks for the tip on pedal side sprockets and order of chain adjustment.

Hope you guys are doing well.

Rick C.