toojung2die

New Member

The look, style, function and sound of the exhaust pipe on a motorized vehicle is very much a matter of personal preference. The mufflers that come with HT engines work OK but leave much to be desired.

I've seen many bikes where the exhaust pipe is an expression of the builders personal style. What matters to you? Form or function? What have you done to customize your exhaust pipe? Lets see what you've come up with to personalize your motorized bicycle.

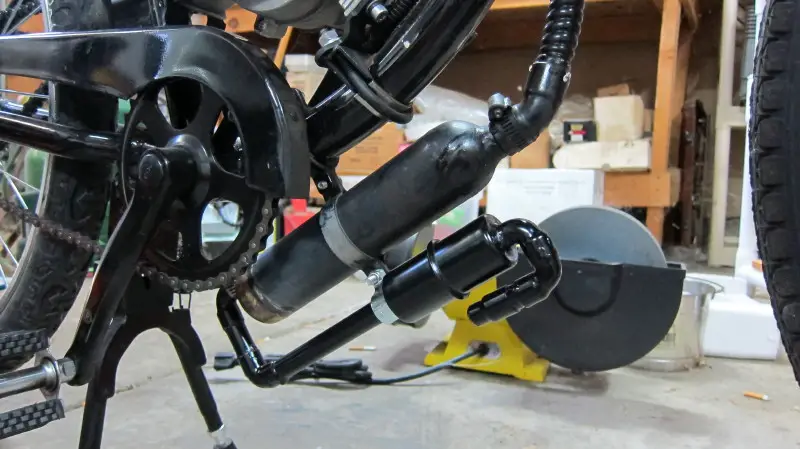

Here is a pipe I made from EMT conduit and an eBay exhaust.

Show us your pipe! How did you do it?

I've seen many bikes where the exhaust pipe is an expression of the builders personal style. What matters to you? Form or function? What have you done to customize your exhaust pipe? Lets see what you've come up with to personalize your motorized bicycle.

Here is a pipe I made from EMT conduit and an eBay exhaust.

Show us your pipe! How did you do it?

Last edited: