You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

what did you do to your motorized bicycle today?

- Thread starter Skarrd

- Start date

dodge dude94

New Member

Re: what did you do to your motor bike today?

Oh, God. Great, you just gave me something else to worry about.

I'm NOT pulling my engine and studs just to measure for a nut. lmao

Oh, God. Great, you just gave me something else to worry about.

I'm NOT pulling my engine and studs just to measure for a nut. lmao

dodge dude94

New Member

Re: what did you do to your motor bike today?

This is true.

I do have 3 nuts in my tool box that might fit...imma have to see what size they are and just buy some more of those.

Just buy an assorted group of nuts.....surely one will fit!! Certainly be cheaper than multiple trips to the nut store...........

This is true.

I do have 3 nuts in my tool box that might fit...imma have to see what size they are and just buy some more of those.

mapbike

Well-Known Member

Re: what did you do to your motor bike today?

There are only two thread types for the 8mm size nuts, 8 x 1.00 or 8 x 1.25

Most common size is the 8 x 1.25, I get mine from here, many types and grades but they are a bulk by, so this may not be the best choice for you.

http://www.mcmaster.com/#nuts/=o3fpgu

This is true.

I do have 3 nuts in my tool box that might fit...imma have to see what size they are and just buy some more of those.

There are only two thread types for the 8mm size nuts, 8 x 1.00 or 8 x 1.25

Most common size is the 8 x 1.25, I get mine from here, many types and grades but they are a bulk by, so this may not be the best choice for you.

http://www.mcmaster.com/#nuts/=o3fpgu

xseler

Well-Known Member

Re: what did you do to your motor bike today?

Stuffed some coarse steel wool up the arse-end of my new exhaust setup this evening. Quietened it down to an acceptable level without affecting the performance increase! I did have to drill a couple holes through the muffler outlet so I could install a keeper wire. The wool wouldn't stay in without it. Guess that means the engine is breathing healthily.

Stuffed some coarse steel wool up the arse-end of my new exhaust setup this evening. Quietened it down to an acceptable level without affecting the performance increase! I did have to drill a couple holes through the muffler outlet so I could install a keeper wire. The wool wouldn't stay in without it. Guess that means the engine is breathing healthily.

Attachments

Huffydavidson

STREETRACER/MANUFACTURER

Re: what did you do to your motor bike today?

Took my fuel line system apart and cleaned it and reinstalled it . Per:mo nthly service .

nthly service .

Took my fuel line system apart and cleaned it and reinstalled it . Per:mo

nthly service .

nthly service .mapbike

Well-Known Member

Re: what did you do to your motor bike today?

Pulled the NT carb off my latest Dax engine, the main jet had been soldered and redrilled with a #73 wire gauge bit which works excellent on all my other engines, but this engine breathes so much better from all the port work and open exhaust that it was running way lean as you will see in the pix I included of the spark plug, I re-drilled the main jet with #71 bit and now its running rich, acting extremely rich actually and had to screw the idle screw a long ways in just to get it to idle and it's still trying to load up so before I make the jet smaller I will look into making sure the float isn't heavy from a hole or just adjusted to high, I just grabbed an extra NT carb out of a box of extra carbs & parts, it looked clean and all seemed good so I put the re-drilled jet in it and stuck in on the engine but, it may have float or needle/seat issues, been so long since I chunked it in that box I don't remember why I quit running it...LOL!

I thought that I had blown the head gasket because of the lean condition overheating but after closer inspection, what had happend is that the head nuts had loosened and that's what caused the squealing noise, the head gasket was leaking but still in good shape, this was the first time I had ever had a head gasket leaking issue and the first time I had actually used my in/lbs torque wrench on one of these little engines, being a grease monkey and small engine tinkerer all my life I just used the criss cross tightening technique on all my engines in the past with flawless results, this time I torqued the nuts down to 120in/lbs used loctite and actually double nutted them with solid stainless steel acorn nuts over the other torqued nuts and still they backed off, 120in/lbs just isn't tight enough in my opinion for the 8mm studs, so as I've always done I just left the torque wrench in its case and tightened the nuts down the way I always have before and again double nutted them, pretty sure that is gonna be problem solved now.

I went to local hardware store and bought 3ft of 3/4 soft copper tubing and a handful of fittings, 90's 45's and collars, maybe next week or later on this weekend I'll have time to work on the exhaust, really no need to try to get a fine tune on the carb until I get the exhaust built and get the Puch head drilled and installed, but I dont plan to run the NT carb long anyway so I just wanted to get it running fairly good so I could put a few break in miles on the engine. got a few goodies in the mail that I had ordered, and finally convinced an Ebay vendor to send me a new wrist pin in place of the defective one I got with the piston set I had ordered from them a week or so ago.

The spark plug in these pix is brand new and has about 25 miles on it, the engine got so dang hot that it caused the whitish blue chalky discoloring, the plug was nice and shiny when I left home on the bike, a testament again to how well the Opti2 protected my engine even though it was running way lean form bad carb tune and leaking head gasket, not sure this engine would have survived this on a conventional 2 smoker oil....

Peace Map

Pulled the NT carb off my latest Dax engine, the main jet had been soldered and redrilled with a #73 wire gauge bit which works excellent on all my other engines, but this engine breathes so much better from all the port work and open exhaust that it was running way lean as you will see in the pix I included of the spark plug, I re-drilled the main jet with #71 bit and now its running rich, acting extremely rich actually and had to screw the idle screw a long ways in just to get it to idle and it's still trying to load up so before I make the jet smaller I will look into making sure the float isn't heavy from a hole or just adjusted to high, I just grabbed an extra NT carb out of a box of extra carbs & parts, it looked clean and all seemed good so I put the re-drilled jet in it and stuck in on the engine but, it may have float or needle/seat issues, been so long since I chunked it in that box I don't remember why I quit running it...LOL!

I thought that I had blown the head gasket because of the lean condition overheating but after closer inspection, what had happend is that the head nuts had loosened and that's what caused the squealing noise, the head gasket was leaking but still in good shape, this was the first time I had ever had a head gasket leaking issue and the first time I had actually used my in/lbs torque wrench on one of these little engines, being a grease monkey and small engine tinkerer all my life I just used the criss cross tightening technique on all my engines in the past with flawless results, this time I torqued the nuts down to 120in/lbs used loctite and actually double nutted them with solid stainless steel acorn nuts over the other torqued nuts and still they backed off, 120in/lbs just isn't tight enough in my opinion for the 8mm studs, so as I've always done I just left the torque wrench in its case and tightened the nuts down the way I always have before and again double nutted them, pretty sure that is gonna be problem solved now.

I went to local hardware store and bought 3ft of 3/4 soft copper tubing and a handful of fittings, 90's 45's and collars, maybe next week or later on this weekend I'll have time to work on the exhaust, really no need to try to get a fine tune on the carb until I get the exhaust built and get the Puch head drilled and installed, but I dont plan to run the NT carb long anyway so I just wanted to get it running fairly good so I could put a few break in miles on the engine. got a few goodies in the mail that I had ordered, and finally convinced an Ebay vendor to send me a new wrist pin in place of the defective one I got with the piston set I had ordered from them a week or so ago.

The spark plug in these pix is brand new and has about 25 miles on it, the engine got so dang hot that it caused the whitish blue chalky discoloring, the plug was nice and shiny when I left home on the bike, a testament again to how well the Opti2 protected my engine even though it was running way lean form bad carb tune and leaking head gasket, not sure this engine would have survived this on a conventional 2 smoker oil....

Peace Map

Attachments

bigbutterbean

Active Member

Re: what did you do to your motor bike today?

Yesterday I fixed my generator mounts. The generator kept getting pushed away from the tire, and so it wasn't charging my battery. My voltage on my battery dropped to 10v. Not good. It took me all evening, but I finally got it mounted where it cant push away from the tire. And if I ever need to loosen it to do anything with the wheel, its entirely moveable. Tomorrow the bike is getting a bit of an overhaul. I'll be installing a manic adapter and 44t sprocket onto a wheel with a shimano cb110 hub and swapping out the old wheel with the Huffy hub and Howard adapter. I'll also be swapping out a 44t chainring for a 36t, and modifying my brake lever to fit a larger toggle switch to control my headlight. My old toggle switch was not working properly, so I went with a heavier duty one, which is currently hose-clamped to my handlebars until I can get it properly mounted. Thats going to take a little dremel work. I also need to make sure both tires have the right amount of air, and after that I think I'll be good to go.

Yesterday I fixed my generator mounts. The generator kept getting pushed away from the tire, and so it wasn't charging my battery. My voltage on my battery dropped to 10v. Not good. It took me all evening, but I finally got it mounted where it cant push away from the tire. And if I ever need to loosen it to do anything with the wheel, its entirely moveable. Tomorrow the bike is getting a bit of an overhaul. I'll be installing a manic adapter and 44t sprocket onto a wheel with a shimano cb110 hub and swapping out the old wheel with the Huffy hub and Howard adapter. I'll also be swapping out a 44t chainring for a 36t, and modifying my brake lever to fit a larger toggle switch to control my headlight. My old toggle switch was not working properly, so I went with a heavier duty one, which is currently hose-clamped to my handlebars until I can get it properly mounted. Thats going to take a little dremel work. I also need to make sure both tires have the right amount of air, and after that I think I'll be good to go.

dracothered

New Member

Re: what did you do to your motor bike today?

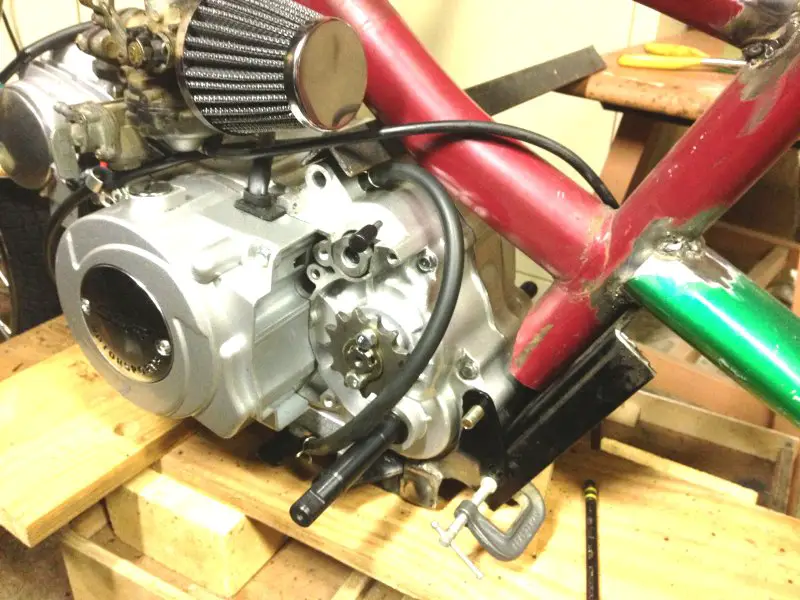

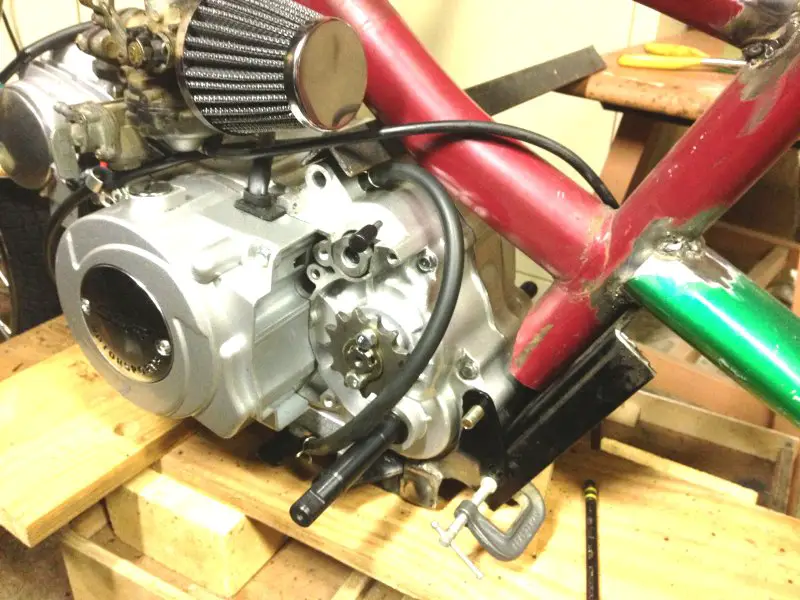

Fabricated this up...

Fabricated this up...

Krealitygroup

New Member

Re: what did you do to your motor bike today?

Fixed Clutch. Epoxied Engine to frame. Ran my first 10mi straight run with hills and light offroad. Repurposed and packed duffel bag for my 3 day trip.If i didn't remember to say this last week. Replaced tires Armadillos with Sharder thron resist tubes

Fixed Clutch. Epoxied Engine to frame. Ran my first 10mi straight run with hills and light offroad. Repurposed and packed duffel bag for my 3 day trip.If i didn't remember to say this last week. Replaced tires Armadillos with Sharder thron resist tubes

Huffydavidson

STREETRACER/MANUFACTURER

Re: what did you do to your motor bike today?

Seriously you're glued your motor to the frame for real. WOW LMAO , Well don't forget the tie wire, duck tape, and bubble gun, I gota felling your gona need it

, Well don't forget the tie wire, duck tape, and bubble gun, I gota felling your gona need it

Seriously you're glued your motor to the frame for real. WOW LMAO

, Well don't forget the tie wire, duck tape, and bubble gun, I gota felling your gona need it

, Well don't forget the tie wire, duck tape, and bubble gun, I gota felling your gona need it

Krealitygroup

New Member

Re: what did you do to your motor bike today?

HAHAHA! Yup. Thats in addition to the standard mount. The expoxy is just overkill.. ALTHOUGH, I keep tons of Duct Tape laying around.. You never know what I might have to hobble together

Seriously you're glued your motor to the frame for real. WOW LMAO, Well don't forget the tie wire, duck tape, and bubble gun, I gota felling your gona need it

HAHAHA! Yup. Thats in addition to the standard mount. The expoxy is just overkill.. ALTHOUGH, I keep tons of Duct Tape laying around.. You never know what I might have to hobble together

bigbutterbean

Active Member

Re: what did you do to your motor bike today?

Today I swapped out my 44t chainring for a 36t and installed my new manic adapter and sprocket on a 26" Wheelmaster wheel with a genuine shimano cb110 coaster brake hub. Its so nice to finally have a reliable wheel again. It rolls so smooth and no more wiggle like I had with the other wheel. I had to re-torque the adapter after my test ride though, because it slipped into my spokes. I had used blue threadlocker, but just didnt torque it down right I guess. So I retorqued and double checked both mounting bolts. This all took me about 6 hours, so I didnt get quite everything done that I wanted. Tomorrow its modifying my brake lever to fit in a larger toggle switch. The old one wasnt reliable. Also adjust front brake and put some air in the front tire. Hopefully will not take me as long as it did today. But I'm just so glad to have a reliable wheel after dealing with that piece of junk Huffy wheel for so long.

Today I swapped out my 44t chainring for a 36t and installed my new manic adapter and sprocket on a 26" Wheelmaster wheel with a genuine shimano cb110 coaster brake hub. Its so nice to finally have a reliable wheel again. It rolls so smooth and no more wiggle like I had with the other wheel. I had to re-torque the adapter after my test ride though, because it slipped into my spokes. I had used blue threadlocker, but just didnt torque it down right I guess. So I retorqued and double checked both mounting bolts. This all took me about 6 hours, so I didnt get quite everything done that I wanted. Tomorrow its modifying my brake lever to fit in a larger toggle switch. The old one wasnt reliable. Also adjust front brake and put some air in the front tire. Hopefully will not take me as long as it did today. But I'm just so glad to have a reliable wheel after dealing with that piece of junk Huffy wheel for so long.

Huffydavidson

STREETRACER/MANUFACTURER

Re: what did you do to your motor bike today?

Rode over to the auto parts store and picked up the new NGK RACING PLUG I order Friday.

Rode over to the auto parts store and picked up the new NGK RACING PLUG I order Friday.

Dan

Staff

Re: what did you do to your motor bike today?

LOL K, ayup!

I used to sail with a guy, a professional marine engineer. He had a special tool box that contained nothing but Duct Tape, bailing wire and weird bits-n-pieces.

No mains, generators or any thing ever failed for long when he was on board. He was an amazing and gifted "Wrench"

Not sure I have ever seen him epoxy parts together though. LOL

I was thinking it is gonna come back to haunt ya but would be funny if it had some sort of positive effect with vibes or some thing.

HAHAHA! Yup. Thats in addition to the standard mount. The expoxy is just overkill.. ALTHOUGH, I keep tons of Duct Tape laying around.. You never know what I might have to hobble together

LOL K, ayup!

I used to sail with a guy, a professional marine engineer. He had a special tool box that contained nothing but Duct Tape, bailing wire and weird bits-n-pieces.

No mains, generators or any thing ever failed for long when he was on board. He was an amazing and gifted "Wrench"

Not sure I have ever seen him epoxy parts together though. LOL

I was thinking it is gonna come back to haunt ya but would be funny if it had some sort of positive effect with vibes or some thing.

CTripps

Active Member

Re: what did you do to your motor bike today?

Top speed is unknown for now.. it cruises at around 40 km/h with less than 1/4 throttle, and feels like it wants to pull out from under me when I open it up from there. On the motor, I cleaned up the intake and exhaust ports; the piston skirt has been cut (on the intake side) to allow maximum intake, it has a 'speed' carb and expansion chamber. Stock 44T sprocket, so it'll hill climb a bit better than my beast's 36T. I'm hoping that when I can afford it I'll be able to put a reed valve on it, that'll give me a major performance change I think. The head and jug have been lapped, as well.

As for the mix, this one's still at around 24:1, due to step up to 40:1 soon. (I use synthetic 2-stroke oil, HP Interceptor I think it's called).

Brilliant idea I'm keeping this one in mind I have a very similar light "the newer bullet style that is and its doing the same thing you described. I can imagine how much brighter it is with all that extra reflective surface surrounding it !! In the bullet light it had what ...zero reflective surrounding area?

Whats top speed on this beast? Also whats your sp[ecial premix? That motor looks clean clean clean !!

Top speed is unknown for now.. it cruises at around 40 km/h with less than 1/4 throttle, and feels like it wants to pull out from under me when I open it up from there. On the motor, I cleaned up the intake and exhaust ports; the piston skirt has been cut (on the intake side) to allow maximum intake, it has a 'speed' carb and expansion chamber. Stock 44T sprocket, so it'll hill climb a bit better than my beast's 36T. I'm hoping that when I can afford it I'll be able to put a reed valve on it, that'll give me a major performance change I think. The head and jug have been lapped, as well.

As for the mix, this one's still at around 24:1, due to step up to 40:1 soon. (I use synthetic 2-stroke oil, HP Interceptor I think it's called).

dracothered

New Member

Re: what did you do to your motor bike today?

Figured out some of my motor mount needs...

Here you can see the direction I am thinking.

Figured out some of my motor mount needs...

Here you can see the direction I am thinking.

Last edited:

dracothered

New Member

Re: what did you do to your motor bike today?

Received my cardboard filled rubber doughnut on the porch today.

Just a little bit skinnier but it should work out great.

Received my cardboard filled rubber doughnut on the porch today.

Just a little bit skinnier but it should work out great.