sportscarpat

Bonneville Bomber the Salt Flat record breaker

re: The Basics, Port & Polish and Port Matching

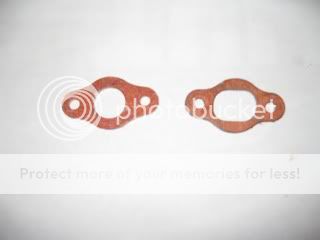

Just a thought from my fabrication perspective, if a somewhat "standard" configuration can be developed for both the intake and exhaust ports on the cylinder I can easily design and laser cut matching flanges to the final port shape. Each port can have it's own shape, that is, and I can cut the two different flanges. We could then use these flanges as templates on the cylinder. Bolt up the bare flange and grind the cylinder until it matches. I could then supply the exhaust flange to weld to the exhaust pipe. I could also take my current intake design and swedge the manifold tube to match the new intake port shape. You would then be ported from the carb, through the cylinder, and right on out the exhaust pipe. Couldn't get any better than that.

Just a thought from my fabrication perspective, if a somewhat "standard" configuration can be developed for both the intake and exhaust ports on the cylinder I can easily design and laser cut matching flanges to the final port shape. Each port can have it's own shape, that is, and I can cut the two different flanges. We could then use these flanges as templates on the cylinder. Bolt up the bare flange and grind the cylinder until it matches. I could then supply the exhaust flange to weld to the exhaust pipe. I could also take my current intake design and swedge the manifold tube to match the new intake port shape. You would then be ported from the carb, through the cylinder, and right on out the exhaust pipe. Couldn't get any better than that.