A 5/8" ID/1 3/8" sealed bearing should be very easy to find.

If uncomfortable, increase the plate size, say, from 1/8" to 3/16"/1/4".

This might be part of what you're looking for:

and this:

If you can't find the correct size bearing, use this:

or this:

Your motor mount plate should be ok, especially if it's welded to the frame.I thought about that. The bearing pillows I have mount pretty well to the engine mount, but I don't feel too comfortable with messing with that piece.

If uncomfortable, increase the plate size, say, from 1/8" to 3/16"/1/4".

This might be part of what you're looking for:

PRO+ Bottom Bracket Conversion Kit Adaptor 68mm American To Euro Cruiser Silver | eBay

Find many great new & used options and get the best deals for PRO+ Bottom Bracket Conversion Kit Adaptor 68mm American To Euro Cruiser Silver at the best online prices at eBay! Free shipping for many products!

www.ebay.com

and this:

FICTION SAVAGE SEALED MID BOTTOM BRACKET 19MM BMX BIKE BB KIT FIT CULT PRIMO | eBay

New Fiction Savage MID Sealed Bottom Bracket Kit 19MM IN BLACK, SILVER, RED OR BLUE. LISTED PRICE IS FOR ONE BOTTOM BRACKET KIT. To many issues sorry.

www.ebay.com

If you can't find the correct size bearing, use this:

5/8" x 3/4" x 3" Shaft Adapter Pulley Bore Reducer Sleeve Bushing Sheave Key | eBay

Find many great new & used options and get the best deals for 5/8" x 3/4" x 3" Shaft Adapter Pulley Bore Reducer Sleeve Bushing Sheave Key at the best online prices at eBay! Free shipping for many products!

www.ebay.com

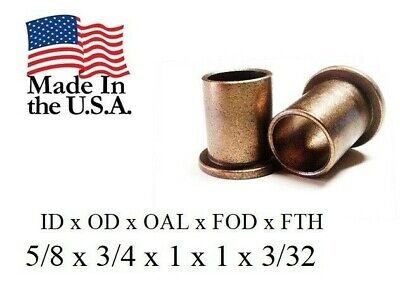

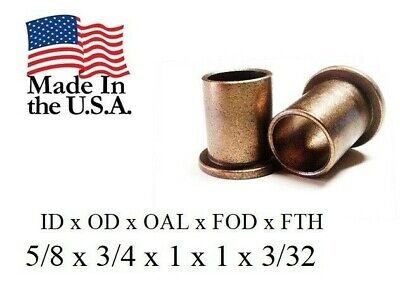

or this:

Qty 2pc, 5/8 x 3/4 x 1 Bronze Flanged Bushing, AMERICAN BRONZE - Made In USA | eBay

Proudly Made in the USA. Our bushings are Ultra lubricated for longer life and smoother operation. Application in Lawn and Garden. Tolerances: OAL, FOD & FTH = +/-.005.

www.ebay.com

Last edited: