Tom I've really enjoyed your tool shop thread and plan on supporting it and those regulars which do the same. That said I'd also like to encourage others to join in, regardless of what they have in the way of tools or what they may lack...including experience.

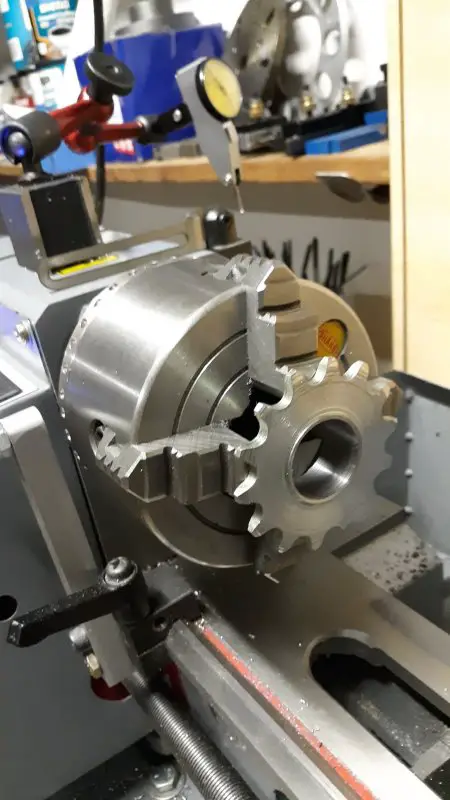

It took me a few hours to clean and reorganize my small shop after a week of using ginders, belt sander, band saw, drill press, mill and especially my mini lathe a 7" x 14" 3/4 hp using mainly the 4", independent, 4 jaw chuck. Daily cleanup was practiced but still needed more at the end.

I've mentioned some projects planned, but noticed some things during the last week, especially effecting the use of my lathe. Yesterday I made sure the face plate matched the lathe's mount perfectly, this had not been done and I finally got round to it.

Next job was to make a mount for a long travel indicator to use primarily behind the carriage to indicate absolute zero and .0015 depth accuracy for boring holes and general lathe drilling and of course for turning. This clamps to the operator side of the way and can be quickly to the chuck side if needed or removed completely for use of the tail stock. Poor boy DRO.

Next is turn and bore a highly accurate bushing for the quick tool change post at the moment this is the least rigid element in my lathe setup. Though I can really tighten the entire post it can and did slip several thou a few times during boring operations last week. I saved the part, but it could have been catastrophic and before I go any further I have to fix it. Super sloppy factory work and zero quality control fitting this bushing/tool post combination on an otherwise good quick change.

To this point I'm really pleased with the new mill. Though in appearance it is the same mill as my last one, it's not. It's noticeably more powerful 3/4 hp rather than 1/2 hp also fit and finish much improved on this Wen labeled mill. Seig is the actual manufacturer but they private label for many distributors Wen being just one. Big, knowlegeable distributors order machines spec'd out as to features and some, like Wen, Grizzley & Little Machine Shop make sure their machines are detailed properly prior to shipping to customers. My mill was actually ready to run after some easy cleanup, oiling and mounting on a solid cabinet.

The mill has to be bolted securely. It's not a table top affair like a drill press, which can be moved about on a work bench. Very top heavy.

Hopefully I'll sort the lathe out this afternoon and get started on electric motor arbor extensions and shaft adaptors tomorrow.

Rick C.