You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bike builders that have machine tools/shops

- Thread starter Tom from Rubicon

- Start date

Tom from Rubicon

Well-Known Member

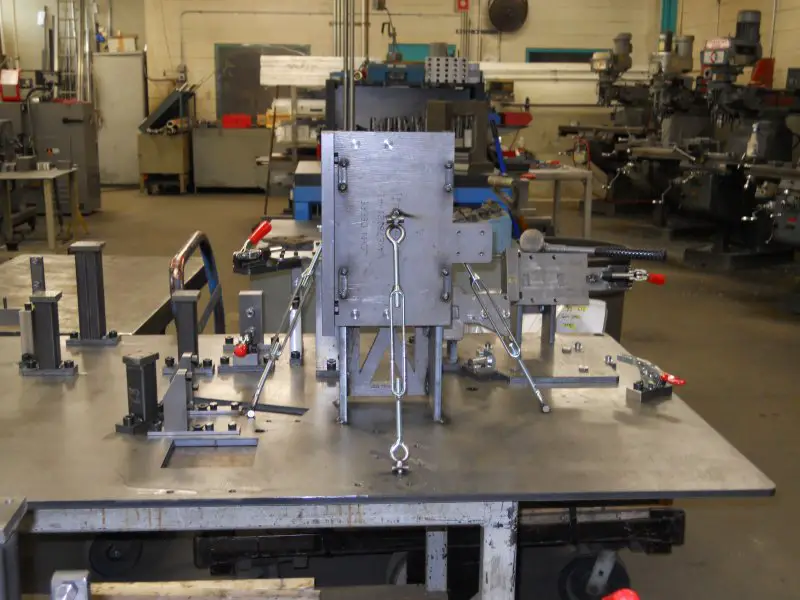

Nice work Curt! Recirculating bearing rail table?

The mount you have for the disc grinder looks patentable.

Lastly, where did you find that style linkage? It is clever beyond words.

Tom

The mount you have for the disc grinder looks patentable.

Lastly, where did you find that style linkage? It is clever beyond words.

Tom

https://www.google.com/search?q=191...0KHdUABxIQ9QEwAHoECAQQBA#imgrc=QoVjOpH2IDmRcM:

Seen the jefferson and just had to try. Lot of time and money into the saw compared to what the $20 saw bracket, LOL. The slides found in junk from paper mill i worked for 35 years. Keep in mind that is just a picture, still need to split springs.........Curt

Seen the jefferson and just had to try. Lot of time and money into the saw compared to what the $20 saw bracket, LOL. The slides found in junk from paper mill i worked for 35 years. Keep in mind that is just a picture, still need to split springs.........Curt

indian22

Well-Known Member

https://www.google.com/search?q=1914+jefferson+motorcycle&tbm=isch&source=iu&ictx=1&fir=QoVjOpH2IDmRcM%3A%2CV9X3JPXLnmbKXM%2C_&vet=1&usg=AI4_-kTWhOHtkUoY5t4-x7KURH4q3le7Ng&sa=X&ved=2ahUKEwiMmo_05_biAhVSRK0KHdUABxIQ9QEwAHoECAQQBA#imgrc=QoVjOpH2IDmRcM:

Seen the jefferson and just had to try. Lot of time and money into the saw compared to what the $20 saw bracket, LOL. The slides found in junk from paper mill i worked for 35 years. Keep in mind that is just a picture, still need to split springs.........Curt

It will Curtis.

allen standley

Well-Known Member

Way Cool Curt!

EZL

Well-Known Member

Nice setup and thanks for the post!Just thought i would show you my cut off saw, mow that it is done.

Table slids on the rods. Going to attempt to split some snow mobile springs to do something like this, for my build i am doing.........Curt

Tom from Rubicon

Well-Known Member

Jefferson, WI is about 45min away from me. And I have looked at those machines many times Curt. Never noticed the trick "To me" sprung axel. I am going to have to make a pilgrimage to Jefferson to get a close look.

Tom

Tom

Tom from Rubicon

Well-Known Member

And now for something completely different.

I had a weldment fixture for John Deere that had a element that had to be vertically square in both axis and I was having a **** of a time. I told the Designer that I didn't foresee a good outcome when I welded it in place. He took me to his tool box, and hands me two turnbuckles.

Says "tack em on to your fixture and dial it in" so I did.

Easy peasy. Worked so good I bought three instead of his two. I will never fight squaring a weldment again.

Thank-you Rorry Rose.

Tom

I had a weldment fixture for John Deere that had a element that had to be vertically square in both axis and I was having a **** of a time. I told the Designer that I didn't foresee a good outcome when I welded it in place. He took me to his tool box, and hands me two turnbuckles.

Says "tack em on to your fixture and dial it in" so I did.

Easy peasy. Worked so good I bought three instead of his two. I will never fight squaring a weldment again.

Thank-you Rorry Rose.

Tom

Think they were made only on deluxe models, some just the front had them, i happen to get some pictures from a show that helped me in the detail..............CurtJefferson, WI is about 45min away from me. And I have looked at those machines many times Curt. Never noticed the trick "To me" sprung axel. I am going to have to make a pilgrimage to Jefferson to get a close look.

Tom

indian22

Well-Known Member

And now for something completely different.

I had a weldment fixture for John Deere that had a element that had to be vertically square in both axis and I was having a **** of a time. I told the Designer that I didn't foresee a good outcome when I welded it in place. He took me to his tool box, and hands me two turnbuckles.

Says "tack em on to your fixture and dial it in" so I did.

Easy peasy. Worked so good I bought three instead of his two. I will never fight squaring a weldment again.

Thank-you Rorry Rose.

Tom

Tom thanks for the share. Old guys and old dogs can learn new tricks...if they pay attention!

Rick C.

MEASURE TWICE

Well-Known Member

Got the Helmet and tried it with my low profile gas mask and also goggles. Bought some new Dewalt Goggles and and protective case which are nicer goggles when ordering the helmet full face and neck shield. Of-course you have to have you head with a slight downward tilt to be safest.

Attachments

indian22

Well-Known Member

Got the Helmet and tried it with my low profile gas mask and also goggles. Bought some new Dewalt Goggles and and protective case which are nicer goggles when ordering the helmet full face and neck shield. Of-course you have to have you head with a slight downward tilt to be safest.

That's something I've got to have MT.

Rick C.

Seen this today, appears to be a tile cutter for the slides, Homemadetools.net is fun to get interesting............Curt

http://www.homemadetools.net/forum/...medium=email&utm_campaign=06-21-19#post136137

http://www.homemadetools.net/forum/...medium=email&utm_campaign=06-21-19#post136137

MEASURE TWICE

Well-Known Member

That's something I've got to have MT.

Rick C.

The Amazon Canada that Fasteddy had shown the link on the last page, I found on the Amazon US page. It was 27.82 USD free shipping, and now has gone up a few dollars.

Other link I had just deleted as price went up while I was writing this, so I will just leave it for you to see whats out there. Note this model I got has the anti-fog screen.

Last edited:

MEASURE TWICE

Well-Known Member

Error Double Post

The Amazon Canada that Fasteddy had shown the link on the last page, I found on the Amazon US page. It was 27.82 USD free shipping, and now has gone up a few dollars.

https://www.amazon.com/Uvex-Bionic-Polycarbonate-Anti-Fog-S8510/dp/B001VY3ACE/ref=sr_1_1_sspa?crid=3JG64JTAV88LI&keywords=uvex+bionic+face+shield&qid=1561164916&s=gateway&sprefix=uvex+bionic+,aps,215&sr=8-1-spons&psc=1

Other link I had just deleted as price went up while I was writing this, so I will just leave it for you to see whats out there. Note this model I got has the anti-fog screen.

Last edited:

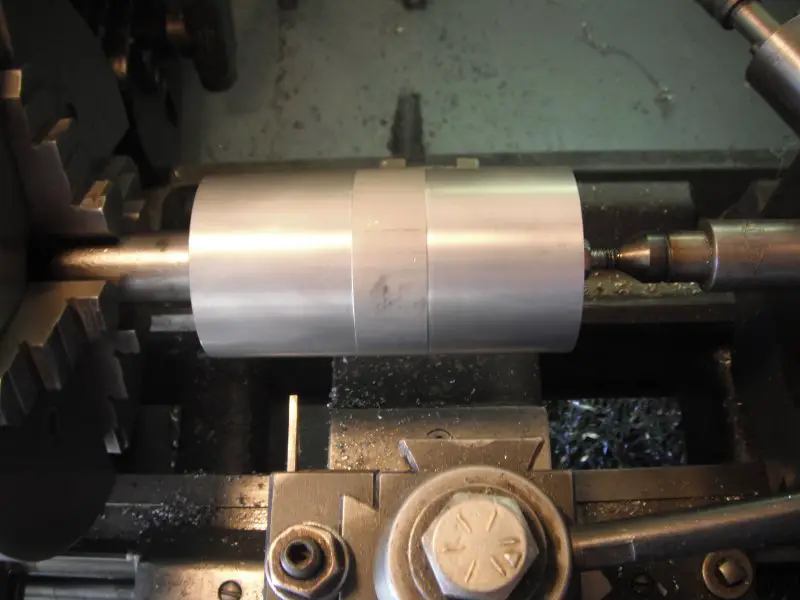

Gonna start chewin' on a chunk of aluminum to make a rear hub.

At 4.81" it's looking a bit wide but the dropouts are 4.96" without spreading. It'll fit. I need all that real estate to get a freewheel, rotor, and a sprocket all on the same axle. Plus whatever I add to one side I have to add to the the other. I thought about bringing the spoke flanges closer together to save some space, but I'm hesitant to fly in the face of 100 years of proven bicycle spoke geometry. Probably not a good idea.

At 550 lbs I have a decently massive benchtop lathe ... but it's still a benchtop lathe! Call it a nibbler. I'm looking at literally hundreds of cuts, which is probably not the most efficient way to build a bicycle, but I got time. Being retired means you never have to be in a hurry.

At 4.81" it's looking a bit wide but the dropouts are 4.96" without spreading. It'll fit. I need all that real estate to get a freewheel, rotor, and a sprocket all on the same axle. Plus whatever I add to one side I have to add to the the other. I thought about bringing the spoke flanges closer together to save some space, but I'm hesitant to fly in the face of 100 years of proven bicycle spoke geometry. Probably not a good idea.

At 550 lbs I have a decently massive benchtop lathe ... but it's still a benchtop lathe! Call it a nibbler. I'm looking at literally hundreds of cuts, which is probably not the most efficient way to build a bicycle, but I got time. Being retired means you never have to be in a hurry.

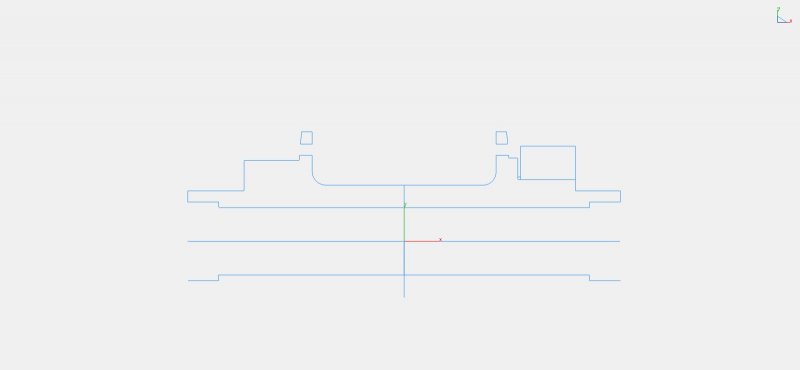

I use a very simple 2D program from ViaCad to keep myself from becoming completely confused. Yeah right! This drawing "should" be all I need to cut this hub out.

The coolest thing about this is you can measure between any 2 points on the drawing. For instance, I'll start with the big cut in the middle but instead of adding up all the dimensions from the edge to get there, I'll just measure it on the computer screen. It'll also print out 1 to 1 templates of whatever you might wanna draw.

Its another one of those I don't know how I ever lived without it tools. $50 well spent.

The coolest thing about this is you can measure between any 2 points on the drawing. For instance, I'll start with the big cut in the middle but instead of adding up all the dimensions from the edge to get there, I'll just measure it on the computer screen. It'll also print out 1 to 1 templates of whatever you might wanna draw.

Its another one of those I don't know how I ever lived without it tools. $50 well spent.

indian22

Well-Known Member

Any body remember mechanical drafting courses in high school? India ink & pen drafting....make a mistake at any point in the process and start over.

How about graph paper? I still use it on simple stuff. Computers have certainly changed and of course massively improved all areas of design and production. Now how about charts, compass, chronograph, astrolabe & sextant navigation: anyone on board or is it to be GPS only?.

Rick C.

How about graph paper? I still use it on simple stuff. Computers have certainly changed and of course massively improved all areas of design and production. Now how about charts, compass, chronograph, astrolabe & sextant navigation: anyone on board or is it to be GPS only?.

Rick C.

![20190619_215103[1].jpg](/data/attachments/90/90838-5155b8a820eb9abd0401d154a5bc8737.jpg?hash=UVW4qCDrmr)