You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bike builders that have machine tools/shops

- Thread starter Tom from Rubicon

- Start date

MEASURE TWICE

Well-Known Member

A few youtube videos explained it to me. One thing maybe said I wondered about. There was a drill press using the reversible tap device attached to tap hole drilled completely through in metal plate both aluminum and steel. It was said that a machine or gun tap was used with the Procunier tapping Head. Those taps are not for using manually.

listen at the 1 minute mark about shavings go out the opposite (bottom) side

This second video on a mod for a tap handle with spring loaded tap follower where a bearing was made to fit I think on the side of the tap follower that went into the tail stock that was free to move axially. What was said that it allowed for an inch or so of spring travel or a little more and that is when I saw the tail stock holding the spring loaded tap handle needing to be re-positioned more in the direction of the lathe head which was locked stationary with the work with the non-through hole being manually tapped.

This second video on a mod for a tap handle with spring loaded tap follower where a bearing was made to fit I think on the side of the tap follower that went into the tail stock that was free to move axially. What was said that it allowed for an inch or so of spring travel or a little more and that is when I saw the tail stock holding the spring loaded tap handle needing to be re-positioned more in the direction of the lathe head which was locked stationary with the work with the non-through hole being manually tapped.

Tom from Rubicon

Well-Known Member

I have the very same Procunier tapping head with a full compliment of tap collets and a slightly newer Walker Turner drill press.

I shoulda made a movie.

When Auto Meter Co. Sycamore, Illinois original owner sold out. New owners were all about profit and chose to out source all in house manufacturing. Made in America, is assembled in America, Fabricated in.......

I was hired as a temp. Tool Maker as tool room staff baled out like rats on a sinking ship. It was.

The Tool Room equipment assets to be liquidated. New owners in a act of feigned magnanimity offered to auction by sealed bid all Tool Room machines except the punch presses. So I bid $50 for the Walker Turner drill press, $875.01 for the 14" Logan Lathe, and $1,100.01 for a Bridgeport that needed some love.

In a second bid a 3phase 5hp air compressor was had for $25.00.

The auction was a joke. Hardly anyone at Auto Meter was compensated well. Lucky for me. Nothing but cherry picking.

This is the place.

Autometer – Best Gauges & Car Equipment

Tom

I shoulda made a movie.

When Auto Meter Co. Sycamore, Illinois original owner sold out. New owners were all about profit and chose to out source all in house manufacturing. Made in America, is assembled in America, Fabricated in.......

I was hired as a temp. Tool Maker as tool room staff baled out like rats on a sinking ship. It was.

The Tool Room equipment assets to be liquidated. New owners in a act of feigned magnanimity offered to auction by sealed bid all Tool Room machines except the punch presses. So I bid $50 for the Walker Turner drill press, $875.01 for the 14" Logan Lathe, and $1,100.01 for a Bridgeport that needed some love.

In a second bid a 3phase 5hp air compressor was had for $25.00.

The auction was a joke. Hardly anyone at Auto Meter was compensated well. Lucky for me. Nothing but cherry picking.

This is the place.

Autometer – Best Gauges & Car Equipment

Tom

Tom from Rubicon

Well-Known Member

Tom from Rubicon

Well-Known Member

Back gear chicken, must be a recipe some wheres.

Reading about Pre Columbian Amazon agriculture in 1491: New Revelations of the Americas Before Columbus - Wikipedia

Terra Preta. Terra preta - Wikipedia

Seems my wood stove is good for other things.

Tom

Reading about Pre Columbian Amazon agriculture in 1491: New Revelations of the Americas Before Columbus - Wikipedia

Terra Preta. Terra preta - Wikipedia

Seems my wood stove is good for other things.

Tom

Tom from Rubicon

Well-Known Member

Ordered this create the highest surface finish i polishing engine ports.

Gave cylinder hones some thought and they produce a nice cross hatch finish. But a Flex-Hone can round corners.

Very important when improving flow characteristics.

Flex-Hone BC 3/4" Honing Tool: Amazon.com: Industrial & Scientific

Tom

Gave cylinder hones some thought and they produce a nice cross hatch finish. But a Flex-Hone can round corners.

Very important when improving flow characteristics.

Flex-Hone BC 3/4" Honing Tool: Amazon.com: Industrial & Scientific

Tom

indian22

Well-Known Member

I haven't tried but I like the idea of a flex tool for port work & 3/4" is a nice size to work with to finish port surfaces.

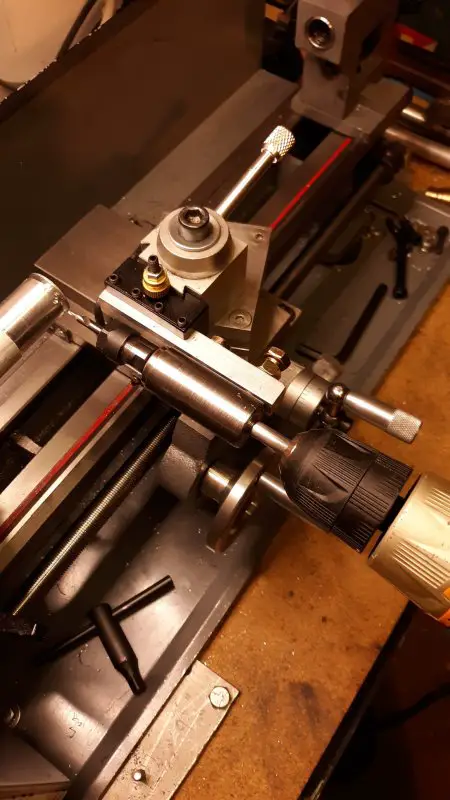

Today I fab the parts to mount a radius turning tool to my lathe. It should be an easy addition and one that I've immediate use for on my miniature engine case work. I think fabbing a divider head for the lathe is next, but I need the cross drill tool completed before I start the dividing head. At some point I'll create a small milling attchment to mount on the lathe too. The compound slide has to be removed to use the radius tool, but for regidity it should come off for the other two tools as well in most cases of use. It's a pretty quick operation to remove the top side so no problems if work is planned out.

I also ordered the wrong face plate so I'll need to make alterations for use on my spindle. I also need to fab a draw bar. Needful things these lathes.

Rick C.

Today I fab the parts to mount a radius turning tool to my lathe. It should be an easy addition and one that I've immediate use for on my miniature engine case work. I think fabbing a divider head for the lathe is next, but I need the cross drill tool completed before I start the dividing head. At some point I'll create a small milling attchment to mount on the lathe too. The compound slide has to be removed to use the radius tool, but for regidity it should come off for the other two tools as well in most cases of use. It's a pretty quick operation to remove the top side so no problems if work is planned out.

I also ordered the wrong face plate so I'll need to make alterations for use on my spindle. I also need to fab a draw bar. Needful things these lathes.

Rick C.

indian22

Well-Known Member

Boy howdy yesterday certainly didn't go as planned, so today is catch up without the chips (fries). I spent most of the day calculating order quantities and dickering over price, shipping and delivery schedules for that which is needed. During all this bother I had a moment of clarity about some lathe modifications which will save me some time making tools or duplicating some of my work.

One of the mini-lathes shortcomings is the steady rests 1.5" diameter work holing limitations. I have an idea for a roller bearing support that is capable of supporting large diameters at any point along the length of the bed and fully adjustable for height. This is a big deal for me at this time so along with the radius turning attachment, it's a priority. Spend some time now that will save time later & in exponential increments.

I've been switching back and forth the three and four jaw chucks & it's become a quick change which allows me to maximize my work holding abilities in chucks. I plan on getting a lot of use from both these chucks.

Rick C.

One of the mini-lathes shortcomings is the steady rests 1.5" diameter work holing limitations. I have an idea for a roller bearing support that is capable of supporting large diameters at any point along the length of the bed and fully adjustable for height. This is a big deal for me at this time so along with the radius turning attachment, it's a priority. Spend some time now that will save time later & in exponential increments.

I've been switching back and forth the three and four jaw chucks & it's become a quick change which allows me to maximize my work holding abilities in chucks. I plan on getting a lot of use from both these chucks.

Rick C.

indian22

Well-Known Member

Radius attachment installed & thought I might share why I like this type tool. I feature that most think that turning balls is all these can be used for so I 'll pass this along and show my proof in photos. I turned a test coupon from one inch aluminum 6061 to demonstrate the utility of the radius turner and here's a list of the operations that were performed on this rod. I first faced the rod stock & remember I used nothing except the carbide cutter installed in the tool for any of these operations except for drilling. Next I turned the rod, then I drilled it on center, I used the radius function to turn a hemisphere followed by turning down several differing rod diameters. I chamfered edges in three different widths and cut two decorative rings in one of these. I also included one decorative slot, then I used the cutter to free hand a 1 3/4" long taper; again this is just a decorative taper. I also used the cutter as a left and right hand tool to face square shoulders into one of the wide slots and later changed one of these square shoulders into a big chamfer. The worked portion of the rod is 8" in length. The total length of the rod was 12" and supported only by the jaws of the three jaw chuck that's turning along way from the ideal of 3 to 1 ratio of material diameter to work stick out without support.

These are roughing cuts which the carbide does well but HSS ground with more of a round nose would finish out well. I didn't bother since this was just a dry run trial for the radius turner. I'll also get round to machining the radius cutter base and mounts to machine tool standards now that I know the concept and design works on the small lathe and has great utility.

The small piece I turned is a part for a miniature carb.

Rick C.

These are roughing cuts which the carbide does well but HSS ground with more of a round nose would finish out well. I didn't bother since this was just a dry run trial for the radius turner. I'll also get round to machining the radius cutter base and mounts to machine tool standards now that I know the concept and design works on the small lathe and has great utility.

The small piece I turned is a part for a miniature carb.

Rick C.

Tom from Rubicon

Well-Known Member

Aren't you getting artsi fartsi

Dumb question. Why you got that hanging out so far? In a three jaw chuck with a one inch grip maybe.

You got more balls than I brains. I see now your want of a steady rest. No offence, but my first thoughts of a steady rest on that little pissant lathe. Carry on Sir.

My two cents, roller bearing contacts. Never liked plain contact fingers using white lead lube. Though it was done.

If I can be of help just holler.

Tom

Dumb question. Why you got that hanging out so far? In a three jaw chuck with a one inch grip maybe.

You got more balls than I brains. I see now your want of a steady rest. No offence, but my first thoughts of a steady rest on that little pissant lathe. Carry on Sir.

My two cents, roller bearing contacts. Never liked plain contact fingers using white lead lube. Though it was done.

If I can be of help just holler.

Tom

indian22

Well-Known Member

LOL, thanks Tom! Addressing your question. I did just 'cause I can & to show how little pressure I was putting on the work piece with this tool & without kicking the work out of three jaw concentricity. The design of the radius tool always will mean exaggerated work stick out , but on work smaller than 1.5" diameter my rest would fine though I opted out of using it for this test, which was an extreme setup on purpose. Once the radius work was completed the tail stock could have been employed, I had already faced and then center drilled prior to cutting the radius, and would always be used on a real fab project. I turned most of the time at about 550 rpm & with carbide on aluminum I was surprised at how well it worked. I had no chatter so I know i was dialed in on speed and feed for this material. HSS would have been a much better tool choice with a nice sharp tool grind. again a hard test for the setup.

This was a difficult test of the tool & machine and was indeed just an artsy show of the capabilities of both for small projects. Once I get round to building a roller bearing center rest for large and long stock, relative to the small dimensions of the lathe, I'll be able to use both a rest and the tail stock support. My Spindle has a max capacity of 7/8" so the 1" material had only jaw length only for support.

All considered I think this tool quite effective on brass and aluminum which are my materials of choice for decorative work.

Rick C.

This was a difficult test of the tool & machine and was indeed just an artsy show of the capabilities of both for small projects. Once I get round to building a roller bearing center rest for large and long stock, relative to the small dimensions of the lathe, I'll be able to use both a rest and the tail stock support. My Spindle has a max capacity of 7/8" so the 1" material had only jaw length only for support.

All considered I think this tool quite effective on brass and aluminum which are my materials of choice for decorative work.

Rick C.

Tom from Rubicon

Well-Known Member

You got a link to that radius cutting tool Rick? Only ones I know of do internal and external radius'.

Holdridge, Model 4-D (Deluxe) Radii Cutter Set | eBay

Tom

Holdridge, Model 4-D (Deluxe) Radii Cutter Set | eBay

Tom

indian22

Well-Known Member

Tom look up in search engine "Pro tool ball turning tool" & that will yield a bunch of ordering variations and some product info as well. Fifty dollars includes shipping. Look for stateside distributors to avoid a wait from India. I noticed a couple after ordering direct and price was almost the same.

The maximum diameter of rod that can be used is 2" but the finished ball will be about 1 7/8" diameter. Likewise a 360 degree ball can't be turned in one operation, almost but you have the rod to part and this leave a flat on the ball. Not a problem if you plan for drilling and tapping & use the ball as a knob, but a real ball has to be turned onto the spot with the flat.

The Holdrige and others like Clausing and Logan etc. have larger versions for turning really large radius. Also note that concave turning is possible bot it requires a drilled or bored center hole of sufficient size to allow room for the cutter to begin it's work. A 90 degree motion on a hemisphere is maximum, but the starts are just a few degrees & the carriage is advanced as the radius is increased with each cut.

Also the compound has to be removed and a sturdy base plate fabricated to secure the cross slide and to elevate the cutting tool height.

Rick C.

The maximum diameter of rod that can be used is 2" but the finished ball will be about 1 7/8" diameter. Likewise a 360 degree ball can't be turned in one operation, almost but you have the rod to part and this leave a flat on the ball. Not a problem if you plan for drilling and tapping & use the ball as a knob, but a real ball has to be turned onto the spot with the flat.

The Holdrige and others like Clausing and Logan etc. have larger versions for turning really large radius. Also note that concave turning is possible bot it requires a drilled or bored center hole of sufficient size to allow room for the cutter to begin it's work. A 90 degree motion on a hemisphere is maximum, but the starts are just a few degrees & the carriage is advanced as the radius is increased with each cut.

Also the compound has to be removed and a sturdy base plate fabricated to secure the cross slide and to elevate the cutting tool height.

Rick C.

Tom from Rubicon

Well-Known Member

You make good points Rick. You can't blame a fellow for coveting a Holdrige, I hope.

May never get there.

No brag, just fact. I can skin a cat better than the local trappers. The reason for doing so is beyond me, when there is no reason to do so, a preponderance of Coons on the other hand.

I never mess with my garbage disposal unit, I like opossums.

Tom

May never get there.

No brag, just fact. I can skin a cat better than the local trappers. The reason for doing so is beyond me, when there is no reason to do so, a preponderance of Coons on the other hand.

I never mess with my garbage disposal unit, I like opossums.

Tom

Last edited:

indian22

Well-Known Member

Old guys estate sales at times yield a sought after accessory or instruments of the trade. Most don't know enough to recognize the tools of the craft or the quality of the marque though and at times a great purchase results.

At my age I'm not looking to buy the best of anything unless it's priced right because the next estate may be mine! Lifetime guarantees don't mean squat to me as my lifetime of use for any item is really quite brief.

Rick C.

At my age I'm not looking to buy the best of anything unless it's priced right because the next estate may be mine! Lifetime guarantees don't mean squat to me as my lifetime of use for any item is really quite brief.

Rick C.

indian22

Well-Known Member

Short double post to two threads with apologies to those who follow both. The lathe chuck divider is complete & works well. 36 position captures a lot of common patterns used in machine work. 5 is a number I use frequently and I will set this up with a 40 tooth sprocket & a slight offset to my 36 hole pattern and may add a couple of others too. but not another 40 holes for sure, too much redundancy and not enough need at this time.

I use a threaded bolt to lock the chuck for each position. This is actually quick enough & absolutely locks with no wiggle as I have a point grind on the set screw and the taper really locks up. If I run into work that requires a lot of divider work I will add a spring loaded lock to replace the set screw, but don't feel it's a thing at this time.

The lock fixture rides on a converted steel & bed way lock & is rock solid & absolutely won't damage the bed way or allow the lock assembly to wander into the running chuck. The back plate I drilled is common to both the 3 jaw and the 4 jaw chucks I use.

All in all I'll rack this up as a success & move on to the tool post motor cross drill and tool grinder attachment, followed by the miniature lathe mill attachment. I've found several options for Z axis slides & small work vises. I'll likely build a plate as well. Vertical travel on the Z is very short 2" to 4" at most so when I say tiny....

Rick C.

I use a threaded bolt to lock the chuck for each position. This is actually quick enough & absolutely locks with no wiggle as I have a point grind on the set screw and the taper really locks up. If I run into work that requires a lot of divider work I will add a spring loaded lock to replace the set screw, but don't feel it's a thing at this time.

The lock fixture rides on a converted steel & bed way lock & is rock solid & absolutely won't damage the bed way or allow the lock assembly to wander into the running chuck. The back plate I drilled is common to both the 3 jaw and the 4 jaw chucks I use.

All in all I'll rack this up as a success & move on to the tool post motor cross drill and tool grinder attachment, followed by the miniature lathe mill attachment. I've found several options for Z axis slides & small work vises. I'll likely build a plate as well. Vertical travel on the Z is very short 2" to 4" at most so when I say tiny....

Rick C.

Attachments

indian22

Well-Known Member

I received bearings pack yesterday and started the cross drill attachment for the lathe last evening. Hope to have it working today as I have immediate need for it. I have the ER collet set and chuck on hand so I can also use the drill attachment for small mills.

Finishing this tool also makes the lathe/mill attachment even more attractive. As some of my slide work was completed earlier the Z side is pretty much a bolt on item now as it can share common points of attachment with other tools.

Rick C.

Finishing this tool also makes the lathe/mill attachment even more attractive. As some of my slide work was completed earlier the Z side is pretty much a bolt on item now as it can share common points of attachment with other tools.

Rick C.

indian22

Well-Known Member

Cross drill attachment fabricated and mounted. First test was to combine the divider head function with the cross drill to drill a 3 hole pattern around a one inch scrap of aluminum rod stock, using a #2 center drill I selected this because it has a ridiculously long point that is really hard not to break off in the work. I hate these things, not center drills, just this type. I was able to drill this without snapping off the tip. I'll check the runout but it seems very good.

I'll use the divider stop to positively lock & keep the chuck located for any single spot setups as well. The cross drill can be quickly swapped on the post for offset end drilling of single or multiple hole locations.

The ER32 collets can hold tools up to 3/4" and down to 1/16" in my set. I need a full set of screw length drills however as space is limited on the y axis.

Small Z table slide next for mill work.

I'll call this a win.

Rick C.

I'll use the divider stop to positively lock & keep the chuck located for any single spot setups as well. The cross drill can be quickly swapped on the post for offset end drilling of single or multiple hole locations.

The ER32 collets can hold tools up to 3/4" and down to 1/16" in my set. I need a full set of screw length drills however as space is limited on the y axis.

Small Z table slide next for mill work.

I'll call this a win.

Rick C.

Tom from Rubicon

Well-Known Member

Ain't you the clever one Rick.  The madness of your method is exposed to all. I like it.

The madness of your method is exposed to all. I like it.

Curt would say Cool Beans.

Your infinitely variable divider, by sprocket change. You hung around machinists better able to think outside the box.

I will make do with a Ebay buy of years ago.. A1 5C Collet Indexing Fixture (kalamazooind.com)

Tom

The madness of your method is exposed to all. I like it.

The madness of your method is exposed to all. I like it.Curt would say Cool Beans.

Your infinitely variable divider, by sprocket change. You hung around machinists better able to think outside the box.

I will make do with a Ebay buy of years ago.. A1 5C Collet Indexing Fixture (kalamazooind.com)

Tom