You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bike builders that have machine tools/shops

- Thread starter Tom from Rubicon

- Start date

Rick, seeing your work did have some influence in my decision.I was hoping & it looks super!

Rick C.

Tom from Rubicon

Well-Known Member

If you ever need to produce another uniform finish and blend tool marks, try a wire wheel.

It produces a uniform burnished finish. Then wash with soap and water.

It produces a uniform burnished finish. Then wash with soap and water.

BoardtrackTank

Active Member

The lathe is the only machine that can reproduce itself, I think that's awesomeCurrently machining a new 14 tooth #35 sprocket for my Sportsman Flyer. With my Logan lathe just because I can.

Fog,

When I restored antique furniture I got into polishing metal. Usually brass beds that were popular. A good friend of mine was an engine builder who happened on an old wrecking yard with 5, 392 Hemi's. He started building them and decided they needed to be fitted out with show polished aluminum parts. Some of it was available but not everything and some of the available parts weren't good enough.

It seems he knew just the fella to help him achieve this. The smartest thing you could have done is soda blast the head. Long before you were finished the lure of polished aluminum would have long disappeared.

Steve.

When I restored antique furniture I got into polishing metal. Usually brass beds that were popular. A good friend of mine was an engine builder who happened on an old wrecking yard with 5, 392 Hemi's. He started building them and decided they needed to be fitted out with show polished aluminum parts. Some of it was available but not everything and some of the available parts weren't good enough.

It seems he knew just the fella to help him achieve this. The smartest thing you could have done is soda blast the head. Long before you were finished the lure of polished aluminum would have long disappeared.

Steve.

PeteMcP

Well-Known Member

I'm with Steve. I too speak from experience when it comes to polished aluminium. It's a super cool look - but sure is high maintenance. Buffing-up my Aero Cycle Car's aluminium body panels was a real chore I wished, at times, I'd never got myself into. By the time I got to polishing the car's tail end, the panels up front were already beginning to oxidize. This kit was enormous fun to build, but in the end I ended up spending more time polishing than driving it.

New project. Not being at all impressed with Chinese carburation I put a 14mm Mikuni on one of these motors during my Granson's mini quad days. That was fine on the quad but there's not enough room on my Schwinn to be able to R and R an air cleaner because of the seat post. Here's a pic.

The stock carb was a flange mount so I had to make that bit of dirty aluminum you see in the pic to spigot mount the Mikuni. I think I can save just enough space to get an air leaner off and on by incorporating the spigot right into the reed valve cover. The flange section will go away.

But I've got to add a little bit of length back because I need an insulator. I've never seen a carb with a metal to metal connection that close to a hot motor. Gotta be a reason for that! So the 1st step will be to modify the stock plastic reed cover into an insulator.

The stock carb was a flange mount so I had to make that bit of dirty aluminum you see in the pic to spigot mount the Mikuni. I think I can save just enough space to get an air leaner off and on by incorporating the spigot right into the reed valve cover. The flange section will go away.

But I've got to add a little bit of length back because I need an insulator. I've never seen a carb with a metal to metal connection that close to a hot motor. Gotta be a reason for that! So the 1st step will be to modify the stock plastic reed cover into an insulator.

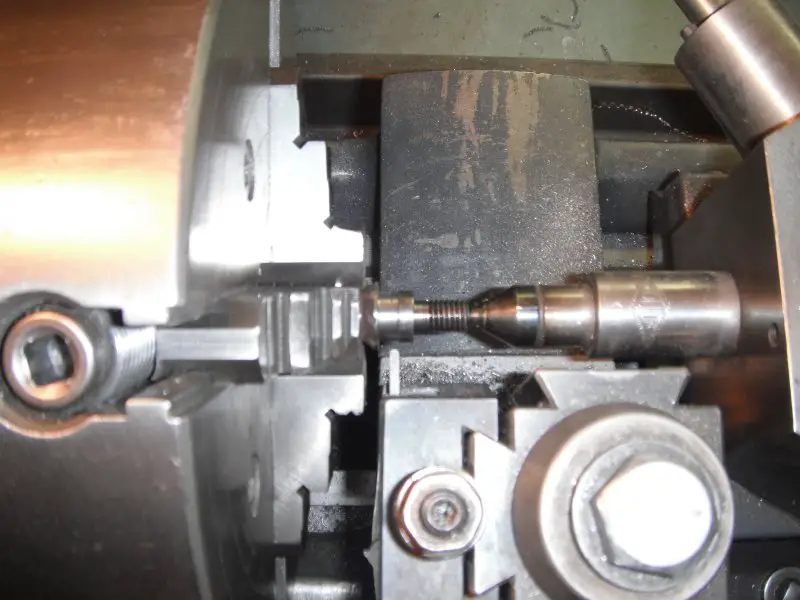

Got sidetracked for a bit over a new pinion gear. I had a 6T that looked more like what a cowboy would stab a horse with than something you'd wanna put a chain on. The acute angle the chain had to achieve on it's way around it was causing an incredible amount of drag too. No good.

So I found what I thought was an 8T replacement ... but no! It threw my chain alignment off by over an 1/8". But thank goodness I own a lathe

Had to grab the teeth in a 4 jaw chuck but that wasn't a good way to keep it straight, so I brought a center into the other end for support. This makes for some tight and tricky work but I was able to cut it to fit and get my alignment back. Noticeable decrease in drag too so it was worthwhile.

Here's what did the job.

So I found what I thought was an 8T replacement ... but no! It threw my chain alignment off by over an 1/8". But thank goodness I own a lathe

Had to grab the teeth in a 4 jaw chuck but that wasn't a good way to keep it straight, so I brought a center into the other end for support. This makes for some tight and tricky work but I was able to cut it to fit and get my alignment back. Noticeable decrease in drag too so it was worthwhile.

Here's what did the job.

Tom from Rubicon

Well-Known Member

More pitchers please.

Tom from Rubicon

Well-Known Member

Just trying to be funny Rick.Sounds like me ordering pizza and beer for the guys!

Rick C

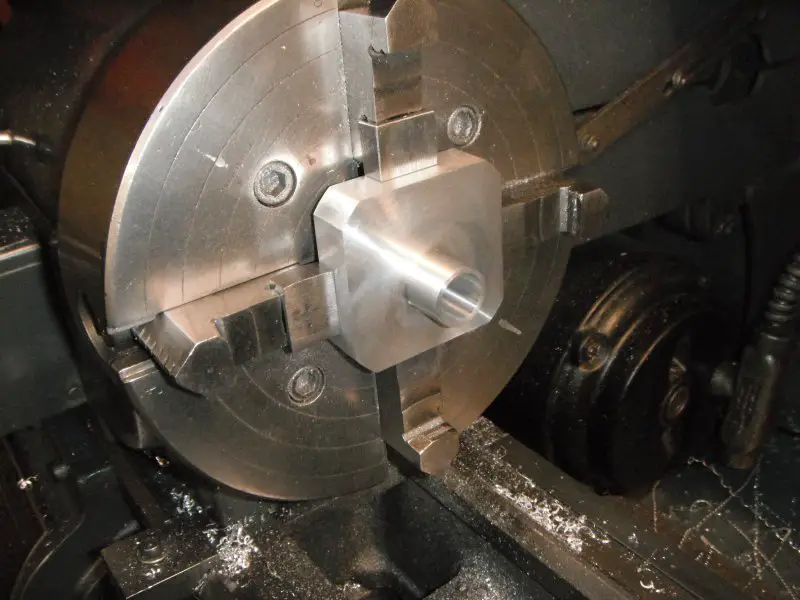

We have a spigot.

It's a start ...

What's got my brain fizzin' is how to do the 4 angled mounting holes. I'll be taking a 20 degree slice offa the back to keep the carb level. BUT the screws have to be pepindicular to the cases while traveling thru the 20. Can't see it in my brain yet. It's still a fizz.

It's a start ...

What's got my brain fizzin' is how to do the 4 angled mounting holes. I'll be taking a 20 degree slice offa the back to keep the carb level. BUT the screws have to be pepindicular to the cases while traveling thru the 20. Can't see it in my brain yet. It's still a fizz.

Tom from Rubicon

Well-Known Member

Spigot fer? Fer mounting holes perp to block I got one of these.

https://www.kalamazooind.com/products/5c-collet-fixtures/a1-5c-collet-indexing-fixture/

Tom

https://www.kalamazooind.com/products/5c-collet-fixtures/a1-5c-collet-indexing-fixture/

Tom

indian22

Well-Known Member

That's a nice quality tool Tom.Spigot fer? Fer mounting holes perp to block I got one of these.

https://www.kalamazooind.com/products/5c-collet-fixtures/a1-5c-collet-indexing-fixture/

Tom

Rick C.

Tom from Rubicon

Well-Known Member

Pretty handy too Rick, I took it to work for a while to simplify set-ups and keep from having to lift the rotary table.

Got with the opposing center for long work too.

Tom

Got with the opposing center for long work too.

Tom

Last edited: