I got that lathe for free but all that means is I started spending from zero. There's a distinct possibility I've spent more on it than it's worth. But I ain't gonna sell it ... so who cares? What I'm really proud of is all my machines have essentially paid for themselves. Before I got sick to death of making them I sold over 400 KTM 50 clutch pullers on E-Bay. Brass piston stops. Early 80's Husqvarna chain guides did well too. In the end tho that turned out be an excellent way to ruin a perfectly good hobby. I want those machines for me!

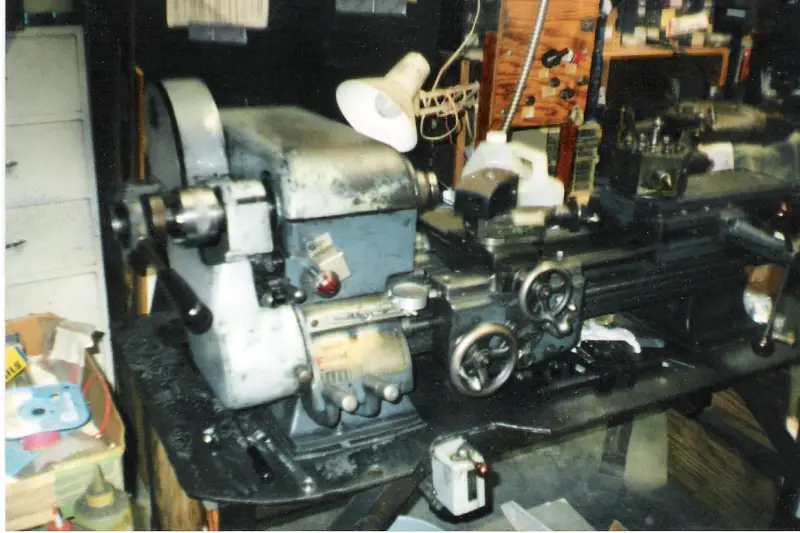

Here's what it looked like when we 1st met:

Now there's a face only a mother could love. And ya know, it takes special nuts like us to see the potential in what most people would regard as a piece of junk. Eventually I got it looking like this:

But it don't look like that now! All that bright metal is stained dark from lubricants and the paint's scratched in the places where a lathe needs to be scratched. All of which is fine with me.

Kind of a cool backstory in that the Grandson of the company founder still supports the lathes as best he can, and that includes the sales records. My lathe, S/N 60214, was 1st sold to Southwest Tool Supply on April 21st, 1952, which was a scant 7 weeks after I was born. I am older than my lathe. But not by much.

And just like my lathe we're both a bit worn out and wobbly! This wasn't no hobby machine. It was a worker bee just like me. Depending on what part of the bed you're on it won't hold a thou for more than 1/2". But it's still incredibly useful. I dunno how I ever lived without it.

Here's what it looked like when we 1st met:

Now there's a face only a mother could love. And ya know, it takes special nuts like us to see the potential in what most people would regard as a piece of junk. Eventually I got it looking like this:

But it don't look like that now! All that bright metal is stained dark from lubricants and the paint's scratched in the places where a lathe needs to be scratched. All of which is fine with me.

Kind of a cool backstory in that the Grandson of the company founder still supports the lathes as best he can, and that includes the sales records. My lathe, S/N 60214, was 1st sold to Southwest Tool Supply on April 21st, 1952, which was a scant 7 weeks after I was born. I am older than my lathe. But not by much.

And just like my lathe we're both a bit worn out and wobbly! This wasn't no hobby machine. It was a worker bee just like me. Depending on what part of the bed you're on it won't hold a thou for more than 1/2". But it's still incredibly useful. I dunno how I ever lived without it.