You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

49cc's on a Schwinn

- Thread starter FOG

- Start date

As usual I'm goin' off the deep end again by making my own cylinder head. I dunno why. Because I can I guess ...

Compression ratio is obviously a big issue but I have this incredible resource at my fingertips we call the internet. I've always wondered what the correct way to calculate CR on a 2 stroke was, and now I know you have to take into account when the exhaust port gets closed.

And there's a calculator for that ...

http://www.torqsoft.net/compression-ratio.html

Luv the net.

Using that a 3cc chamber yields 9.38 to 1. Now I just gotta figure what dimension it takes to make a 3cc chamber. Back to the net ...

Compression ratio is obviously a big issue but I have this incredible resource at my fingertips we call the internet. I've always wondered what the correct way to calculate CR on a 2 stroke was, and now I know you have to take into account when the exhaust port gets closed.

And there's a calculator for that ...

http://www.torqsoft.net/compression-ratio.html

Luv the net.

Using that a 3cc chamber yields 9.38 to 1. Now I just gotta figure what dimension it takes to make a 3cc chamber. Back to the net ...

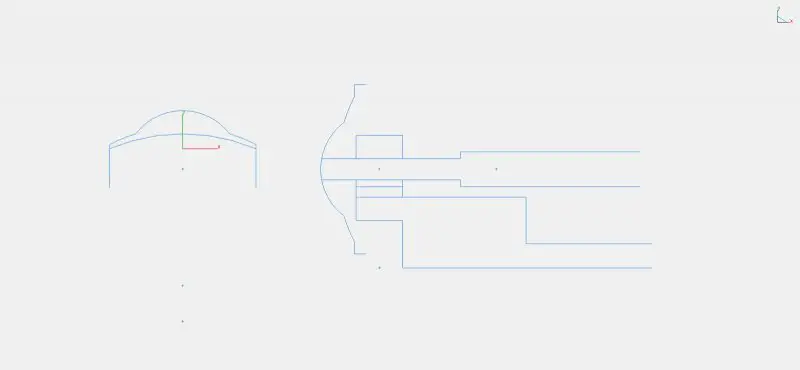

I found an online calculator for the volume of a dome which led to this ...

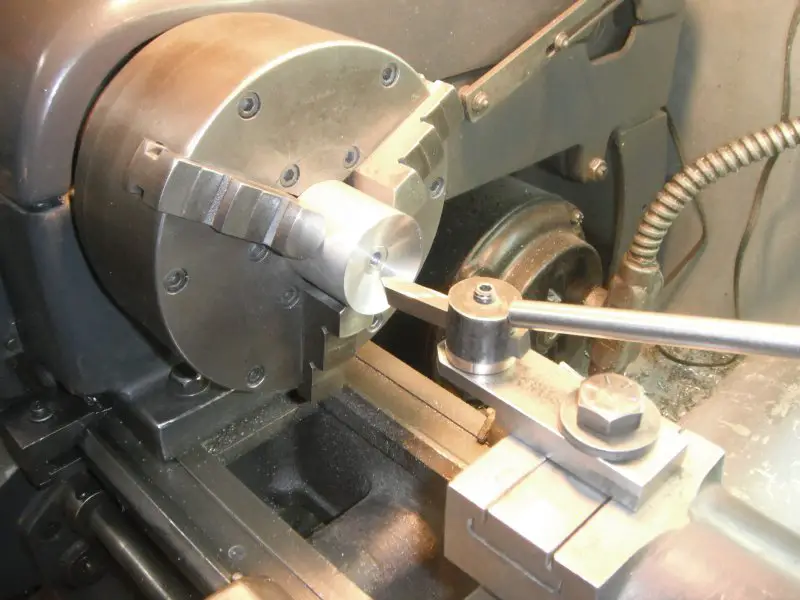

All that stuff on the right side is for the wee little cutter I gotta build next. I just kinda eyeballed the 1st one, no drawing, and it won't cut the combustion pocket without runnin' into the squish cut. It's good down to a radius of an inch or so but I need to reach in there and cut a 5/8" radius for the combustion pocket.

It's good down to a radius of an inch or so but I need to reach in there and cut a 5/8" radius for the combustion pocket.

That cutter ain't cuttin" in that far. Too big.

All that stuff on the right side is for the wee little cutter I gotta build next. I just kinda eyeballed the 1st one, no drawing, and it won't cut the combustion pocket without runnin' into the squish cut.

That cutter ain't cuttin" in that far. Too big.

JerryAssburger

Active Member

NICE BEAUTIFOLD BUILD, FOG! Excellent choice of color, and yours is the first build I've seen using the Pocket-Bike Motors that are all over Ebay for cheap! Smoother/better that a China Girl? Inquiring Minds want to know! Keep up the amazing work!