Whoops..doesn't fit

- Thread starter She

- Start date

any chance you could post a picture,or a link to one?

my photo posting skills suck,so i cant help you in that respect.

type of kit you are installng may help too.

my photo posting skills suck,so i cant help you in that respect.

type of kit you are installng may help too.

Last edited:

If you can fit the engine in the frame, at the right angle. Then yes you can probably do something there. Pictures will help.LOL I thought I measured right ..it doesn't fit in my frame. I can get the engine in but the screws aren't long enough. Its because it is a very tight fit. Anything I can do(besides to get a new bike)? I know they make screw extenders..would that work?

If i am reading this right, you just need longer mounting studs. You can remove the ones on the engine and go to home depot or most auto parts stores or hardware stores and get long enough bolts to replace the all thread studs you have.

If you are set on using the frame you have, you can make the engine fit, and at the same time fit it correctly, which is very important. You have a couple of options available to you.

First do not use stud extenders...you can get Metric 6X1.0 Metric grade 8.8 (USS Grade 5) in any length you need. The OEM studs don't hold up even without extenders. In fact extenders will most likely get in the way of the mounting on the tube, causing you to spread the studs apart to fit, causing stress on the case, and causing more damage.

Second should you need extra clearance in the frame, you can do away with the OEM front, rear or both mounts.

Picture sure would help.

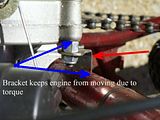

These photos depict correct engine mounting...

Engine without the rear OEM mount. Increases clearance about a extra 1/2" to 1", Enables the engine to sit lower in a frame.

Correct mount fitting

incorrect fitting

or

or

First do not use stud extenders...you can get Metric 6X1.0 Metric grade 8.8 (USS Grade 5) in any length you need. The OEM studs don't hold up even without extenders. In fact extenders will most likely get in the way of the mounting on the tube, causing you to spread the studs apart to fit, causing stress on the case, and causing more damage.

Second should you need extra clearance in the frame, you can do away with the OEM front, rear or both mounts.

Picture sure would help.

These photos depict correct engine mounting...

Engine without the rear OEM mount. Increases clearance about a extra 1/2" to 1", Enables the engine to sit lower in a frame.

Correct mount fitting

incorrect fitting

or

or

Last edited:

Yes that has been done pretty easily. Just a little fabrication skills, some tools and imagination are needed to do it.Another question can I put an engine that suppose to go on the fork in the back?

I would start be mounting a front fork to the rear axle, tilted back a little, and using a strut attached to the top of it and the seat stays. Then mount the engine on the forks.

Someone in the DIY i think, recently did a rear mount Solex clone like this but he used strap steel instead of forks.

Last edited:

I used a round file to make adjustment to my motor mounts.

They were somewhat like shown in Alf's tutorial as 'incorrect'.

Because I fitted the mounts well to the tube, I have had zero problems with the crummy china mm studs, though I should replace them with better quality anyway.

Good luck

rc

They were somewhat like shown in Alf's tutorial as 'incorrect'.

Because I fitted the mounts well to the tube, I have had zero problems with the crummy china mm studs, though I should replace them with better quality anyway.

Good luck

rc

I cheated there on several of my builds by cutting several strips of lead flashing sheet, of varying width to stick in there to shim out the space.I used a round file to make adjustment to my motor mounts.

They were somewhat like shown in Alf's tutorial as 'incorrect'.

Because I fitted the mounts well to the tube, I have had zero problems with the crummy china mm studs, though I should replace them with better quality anyway.

Good luck

rc

When I clamped it down hard,(stock studs) the lead mashed and conformed to the space. After tightening a couple more times after some use, this has worked well. One bike has almost 2000 miles now with no engine mount problems.

I have built 7 chinagirls. I never any trouble with the stock studs at all. Just made sure they were seated well just before assembeling.

wayne z

That's the key, making sure that the mounts are mounted squarely on the tubes, unfortunately most bikes don't have a frame (V of 75 deg or even close) that will allow it. I use 3/4" copper couplings but lead sounds like a good idea. Copper is accessible in just about any hardware store, and although not as easy to work with as lead is workable.

That's the key, making sure that the mounts are mounted squarely on the tubes, unfortunately most bikes don't have a frame (V of 75 deg or even close) that will allow it. I use 3/4" copper couplings but lead sounds like a good idea. Copper is accessible in just about any hardware store, and although not as easy to work with as lead is workable.

Last edited:

I agree with Alf.

Copper is superior to using Pb.

The lead will just get hammered out by the vibration.

Even Al beverage cans cut for shim stock get hammered and become worthless in many applicatons.

Best

rc

Copper is superior to using Pb.

The lead will just get hammered out by the vibration.

Even Al beverage cans cut for shim stock get hammered and become worthless in many applicatons.

Best

rc

I like that idea. Tomorrow to the hardware store.......I cheated there on several of my builds by cutting several strips of lead flashing sheet, of varying width to stick in there to shim out the space.

When I clamped it down hard,(stock studs) the lead mashed and conformed to the space. After tightening a couple more times after some use, this has worked well. One bike has almost 2000 miles now with no engine mount problems.

I have built 7 chinagirls. I never any trouble with the stock studs at all. Just made sure they were seated well just before assembeling.

Yes, Lead is easily worked and easy to get.

I bought a lead sheet vent stack at the local hdw store years ago. A lot of the flat part is missing now. I use it in my bench vise and lathe chucks to prevent damage to my work from clamping pressure.

I bought a lead sheet vent stack at the local hdw store years ago. A lot of the flat part is missing now. I use it in my bench vise and lathe chucks to prevent damage to my work from clamping pressure.

Hmm, for something to get hammered, there has to be movement. If there's movement then somethings loose or not fitting good.I agree with Alf.

Copper is superior to using Pb.

The lead will just get hammered out by the vibration.

Even Al beverage cans cut for shim stock get hammered and become worthless in many applicatons.

Best

rc

My lead hasn't hammered out I guess because I was dillegent about checking and keeping both engine joints tight.

Also because it conforms so well, there's good surface contact and conformity to spread out the load, and lead, like all metals, work hardens some.

Copper is superior, but lead is easy LOL

I'll just add that I have used lead sheet for years with great success. I started using it as a vibration absorber, and it seems to work o.k. for that as well.

Actually, your miles prove the value of the test, Wayne.

I'd sooner file the mount, though.

And, grabbing a short three/quarter nipple and cutting it with the snips would be easier for me, too.

...hmmm... I guess they DO use babbitt bearings, don't they!

.

I'd sooner file the mount, though.

And, grabbing a short three/quarter nipple and cutting it with the snips would be easier for me, too.

...hmmm... I guess they DO use babbitt bearings, don't they!

.