I got an idea from watching multi-speed RC cars shifting at certain RPMs into a higher gear. At a race last year I mentioned to Briggsbiker, Anthony, that it would be cool to build one for my race bike. He said he had one on an old Rupp mini-bike and that it worked okay. I researched it online and discovered Maxtorque was producing the proper components and they were being offer by someone for restorations. Anyway, I set out to duplicate their system. I started by buying the only part that was different than any other minibike, the double sprocket clutch sold by BMI. Somewhere along the way I chose to enclose it all into a removable case as it was way too bulky to have the clutch on the motor and the jackshaft on the frame. Also I wanted to include a pedal start mechanism integrated into the same case.

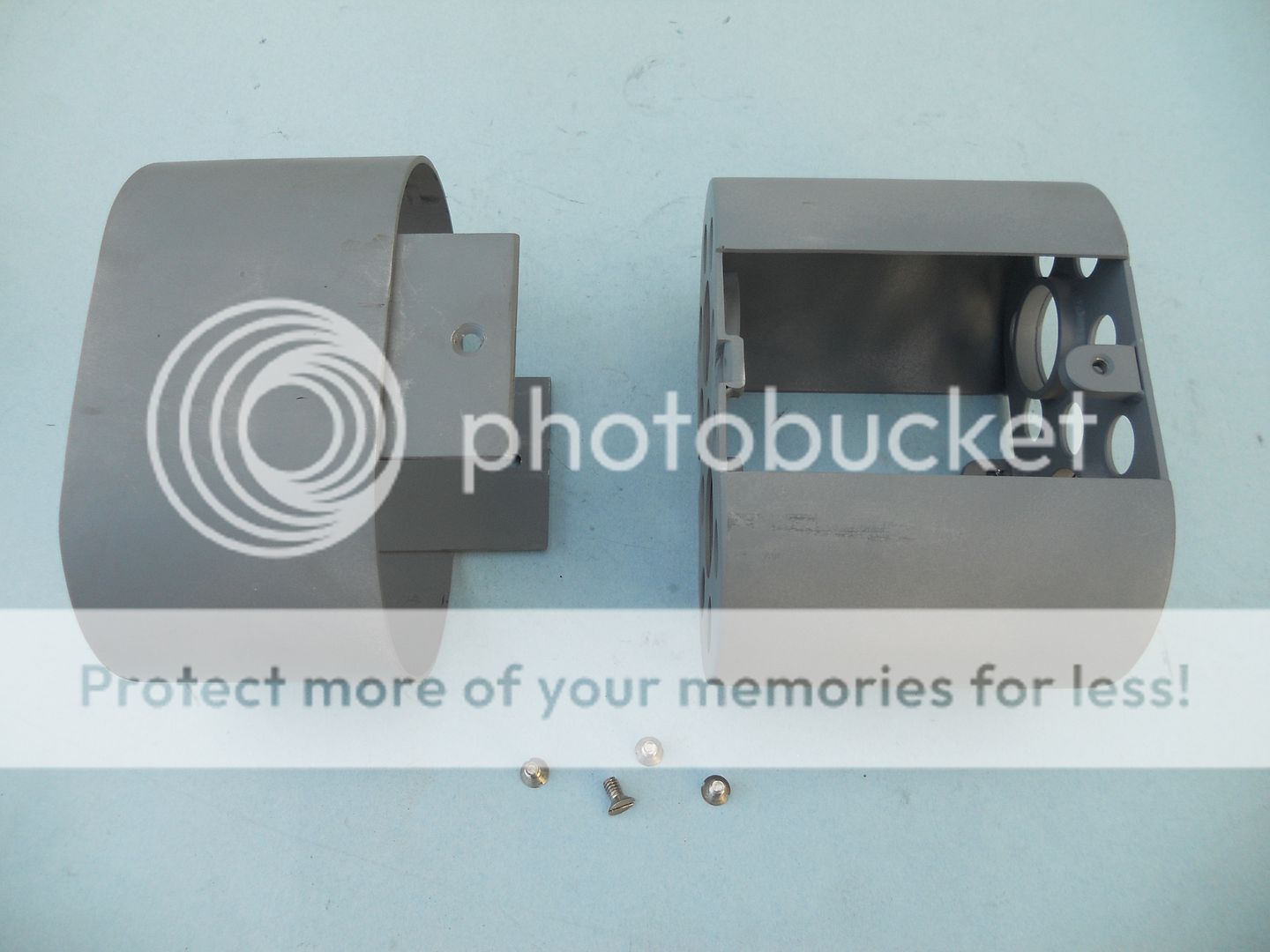

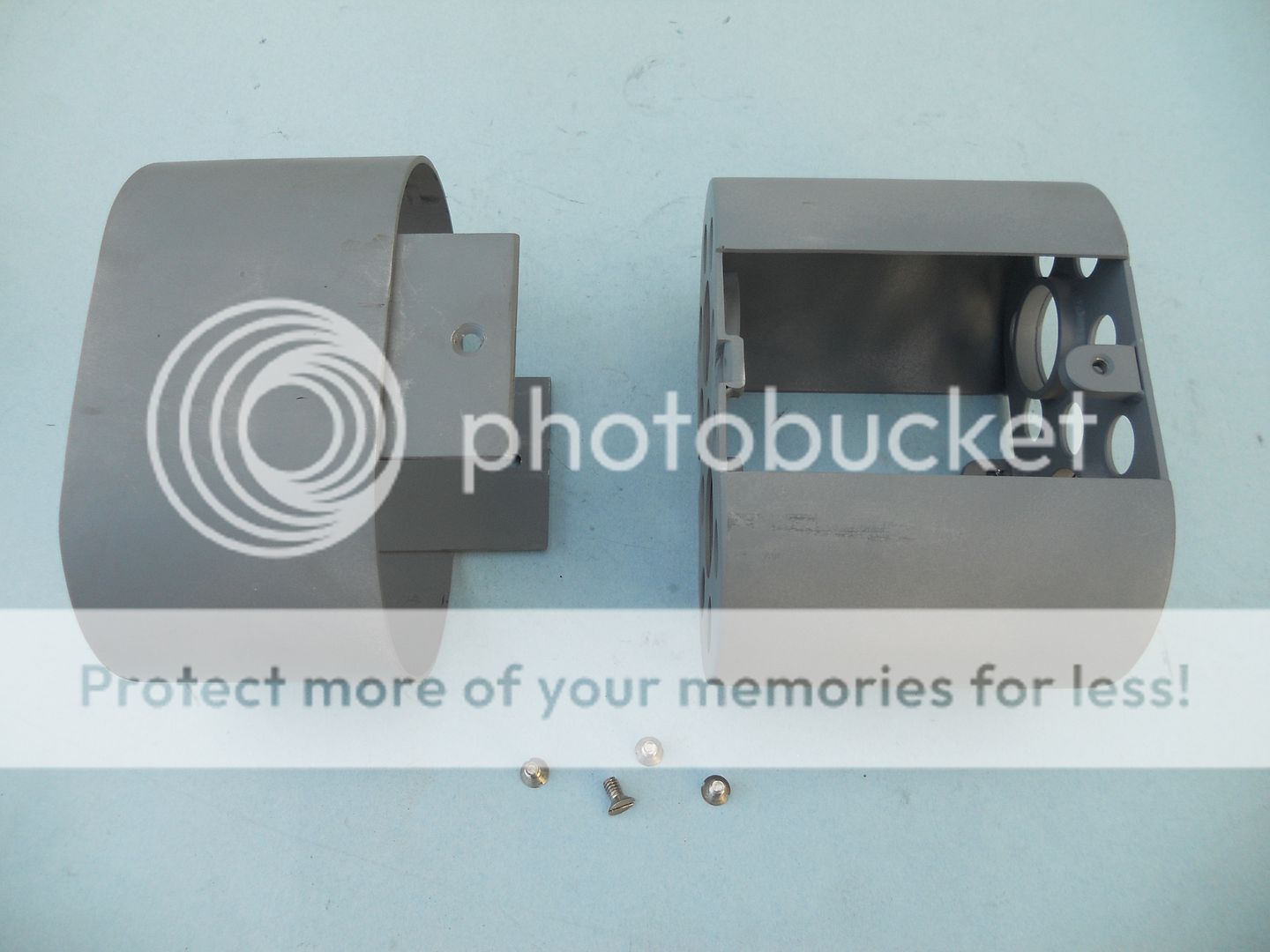

I started with the case, forming pieces of 1/8'' flat strap into rounded end caps and flat sides to weld onto them. Added rings to hold bearings and mounting tabs.

Got all that welded together.

Then I had to make a similar part for it all to slip into.

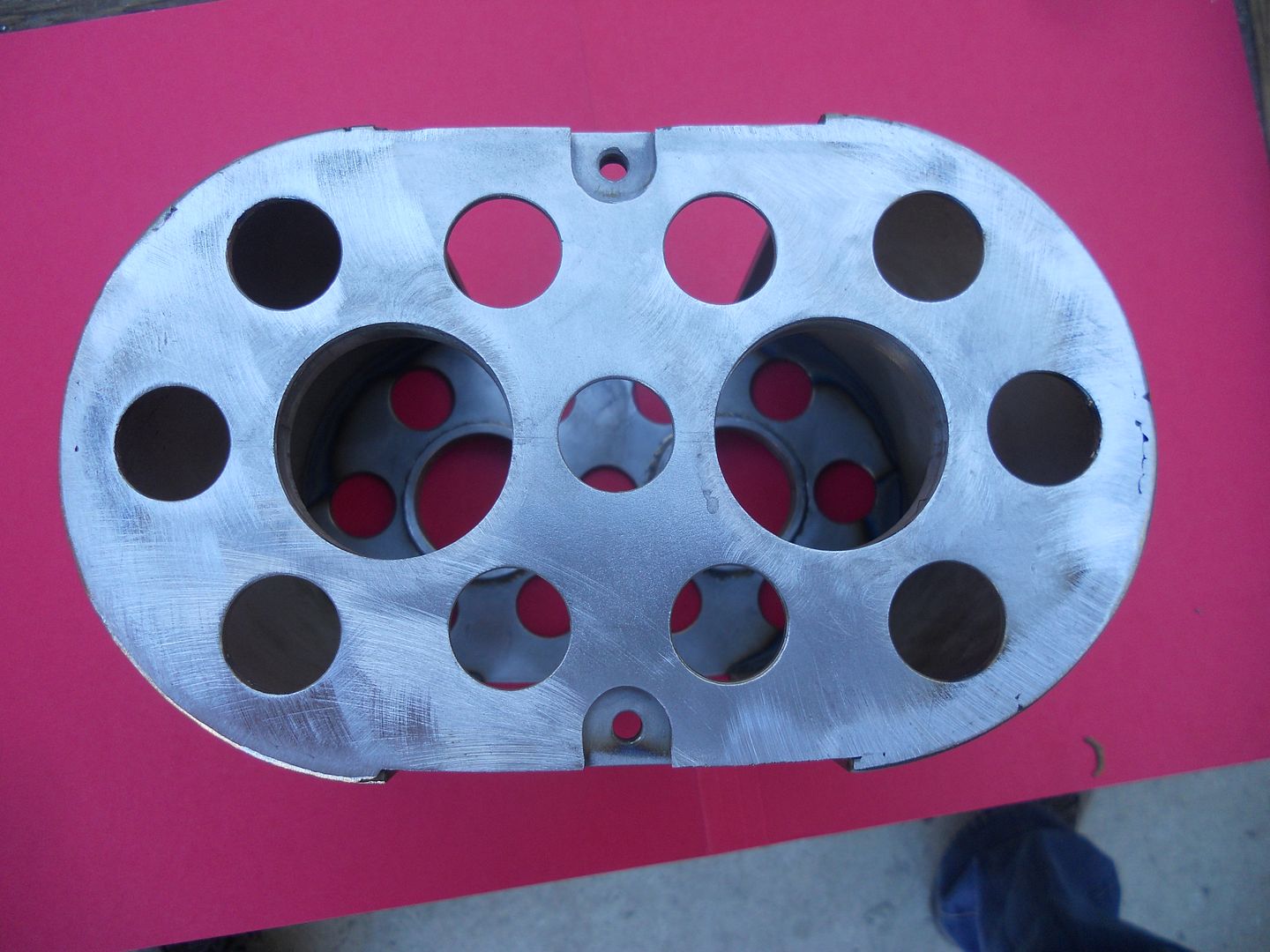

I started with the case, forming pieces of 1/8'' flat strap into rounded end caps and flat sides to weld onto them. Added rings to hold bearings and mounting tabs.

Got all that welded together.

Then I had to make a similar part for it all to slip into.