Velodrome

Well-Known Member

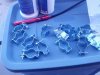

K... Bairdco recnetly had a situation with his front brake that wadded him up pretty good. The thing came loose; wrapped the brake cable around the axle and locked the front end resulting in a terminal stoppie... Next stoppey was the trauma bay and weeks off work with busted ribs and other interesting things... I have had a similar close call when using a single "adell" clamp to secure the arm on my Sturmy Archer 90mm drum on my Felt Twin build. Clamp broke; again, wraping up the cable and locking the front wheel. lucky for me I was only going bout 5-10 MPH and coming to a stop anyways. Leary of the clamp I pulled the trick of DOUBELING the adell clamp inside the same rubber guard / skuff preventor thingy. BUT! I have never had confidence in the "fix" and have been very leary of using the front brake to anything beyond half power. I've been looking for MONTHS for an adiquate solution and I think I have found an answer to the issue. !!! ~ BEHOLD ~ !!! THE 1" Rigid EMT IMC Conduit Pipe Clamp Hangers !!!

Attachments

Last edited: