You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Old Guys Simplex moto-peddle bike

- Thread starter indian22

- Start date

indian22

Well-Known Member

Thanks Danny. I'll be working on a mounting plate for the scooter motor today. The photo shows how compact the brushless motors are. There are 8 threaded mounting holes on the face of their case and locating the precise position of each of these holes on an aluminum plate is my project this morning. This completed plate and motor will then be bolted to the V-twin motor case on the output side of the steel motor housing. This side of the case will be completely welded & the opposite case side plates are removable for interior case access.

The electric motor is vented on the back side (pedal chain side) only so venting is required on this removable plate. The motor case is completely open on the bottom for cooling as well. If I encounter heating issues I've room to tube wrap the motor for liquid cooling, the aluminum fuel tank would make a great coolant tank. I don't see cooling as a big issue however I've reasoned appropriate responses if heat becomes a big problem.

Going with high power and small motor case size is new to me, but my other electric projects have certainly equipped me to expect some difficulties. I've studied the electric scooter scene and found the weight of the best high performance models to be between 70 and 100 lbs. unloaded. Not unlike that of cruiser style CG equipped moto bikes. Power to weight of a kit bike is miniscule compared to that of a 2500 watt electric so I'd think 4800 watts even more impressive. Torque on the electrics is huge. Compact size yet long on performance. The premium scooters are heavy and fast 40 to over 50 mph fast on tiny wheels. Same with the skateboard setups, only much lighter in weight. I mention speed only as reference points; my performance goals are still high torque & relatively modest top speed of around 40 mph..

I'll be playing with several battery and controller setups as well. Gearing comparisons between 10" or 12" wheel size and 26" bike size is sketchy in my mind at this point, but starting with 56 tooth on the rear and 12 tooth up front will determine if a reduction drive is required to lower the ratio. I'd not think raising the final drive ratio is even a thing.

Rick C.

The electric motor is vented on the back side (pedal chain side) only so venting is required on this removable plate. The motor case is completely open on the bottom for cooling as well. If I encounter heating issues I've room to tube wrap the motor for liquid cooling, the aluminum fuel tank would make a great coolant tank. I don't see cooling as a big issue however I've reasoned appropriate responses if heat becomes a big problem.

Going with high power and small motor case size is new to me, but my other electric projects have certainly equipped me to expect some difficulties. I've studied the electric scooter scene and found the weight of the best high performance models to be between 70 and 100 lbs. unloaded. Not unlike that of cruiser style CG equipped moto bikes. Power to weight of a kit bike is miniscule compared to that of a 2500 watt electric so I'd think 4800 watts even more impressive. Torque on the electrics is huge. Compact size yet long on performance. The premium scooters are heavy and fast 40 to over 50 mph fast on tiny wheels. Same with the skateboard setups, only much lighter in weight. I mention speed only as reference points; my performance goals are still high torque & relatively modest top speed of around 40 mph..

I'll be playing with several battery and controller setups as well. Gearing comparisons between 10" or 12" wheel size and 26" bike size is sketchy in my mind at this point, but starting with 56 tooth on the rear and 12 tooth up front will determine if a reduction drive is required to lower the ratio. I'd not think raising the final drive ratio is even a thing.

Rick C.

Nightster

Well-Known Member

How a massive part of the internet went down for an hour

https://www.cnn.com/2021/06/09/tech/fastly-internet-outage/index.html

https://www.cnn.com/2021/06/09/tech/fastly-internet-outage/index.html

indian22

Well-Known Member

Steel crank case welded up, except for the frame mount tabs and I'll wait till my 11/8" and 1". tube clamps arrive. One order cancelled because delivery to a Ca. address and I'm in Indian Territory (no ocean front property here) but I've other stuff somewhere between here and China still moving about....no need to rush it seems, or worry.

I ordered another motor controller today as well. It's a VESC open source that I've been meaning to give a try. It's quite small compared to most e-bike controllers which can't handle half the amps and this one is fully configurable up to 60 volts and 175 amps. I'm thinking it will go into the "Old Crow build & make it a really intelligent old bird. I really don't like the controller I have mounted in it.

Rick C.

I ordered another motor controller today as well. It's a VESC open source that I've been meaning to give a try. It's quite small compared to most e-bike controllers which can't handle half the amps and this one is fully configurable up to 60 volts and 175 amps. I'm thinking it will go into the "Old Crow build & make it a really intelligent old bird. I really don't like the controller I have mounted in it.

Rick C.

indian22

Well-Known Member

Ordering stuff from Bangood in my experience is so sketchy but I keep doing it

Delivery time is typically either long or really long and weeks rather than days with the occasional months. I'm patient and that works in their favor I suppose.

Is Alibabba any quicker?

Rick C.

Delivery time is typically either long or really long and weeks rather than days with the occasional months. I'm patient and that works in their favor I suppose.

Is Alibabba any quicker?

Rick C.

PeteMcP

Well-Known Member

My story is similar to Steve's. Everything I've ever ordered from Alibaba or AliExpress has shipped via air (invariably post free) and has been delivered to me in the UK quickly or reasonably quickly in my experience. Mostly, items turn up faster than the advised postal times. Biggest plus in these companies favour is I'm never hit with extortionate import charges. Only rarely, on larger items such as the drop loop frame I ordered last year, have I had to pay import taxes. And even then, the nominal tax I paid was calculated on the grossly under-declared value of the item sent from the Orient.

eBay is full of chancers re-selling the exact same goods these Oriental manufacturers/sellers offer. It's just that you'll have to pay two or three times the price - often plus postage - for the pleasure of buying from within your own shores.

On UK eBay I've noticed the trend is shifting towards 'drop shipping', with many Far Eastern sellers setting up warehouses full of China-made goods. Not just the usual gaudy, plastic crap. Several cnc'd alloy components I've recently ordered for my latest build have shipped direct from within the UK and I've received them within three or four days. eg; a Vincent-style STOP/tail lamp and side-mount license plate costing a mere 17 quid showed up after four days. You just need to be careful when ordering from such sellers that they actually are in the UK - and not just partial to randomly displaying the UK's Union Jack flag in their adverts.

eBay is full of chancers re-selling the exact same goods these Oriental manufacturers/sellers offer. It's just that you'll have to pay two or three times the price - often plus postage - for the pleasure of buying from within your own shores.

On UK eBay I've noticed the trend is shifting towards 'drop shipping', with many Far Eastern sellers setting up warehouses full of China-made goods. Not just the usual gaudy, plastic crap. Several cnc'd alloy components I've recently ordered for my latest build have shipped direct from within the UK and I've received them within three or four days. eg; a Vincent-style STOP/tail lamp and side-mount license plate costing a mere 17 quid showed up after four days. You just need to be careful when ordering from such sellers that they actually are in the UK - and not just partial to randomly displaying the UK's Union Jack flag in their adverts.

indian22

Well-Known Member

Motor mount plated cut out and drilled. I used two 1/8" thick 6061 aluminum to mount the e motor to and bolt all to the 12 gauge steel case. I don't think it's going to flex any.

After much research and thought I've decided not to run a reduction gear just rely on 5 to one direct drive and lots of amps to get rolling. Neither the bike nor me are very heavy so the worst that can happen is I might have to add reduction gearing after a test ride and I've plenty of experience in that particular fabrication.

All in all coming together ok to this point.

Rick C.

After much research and thought I've decided not to run a reduction gear just rely on 5 to one direct drive and lots of amps to get rolling. Neither the bike nor me are very heavy so the worst that can happen is I might have to add reduction gearing after a test ride and I've plenty of experience in that particular fabrication.

All in all coming together ok to this point.

Rick C.

indian22

Well-Known Member

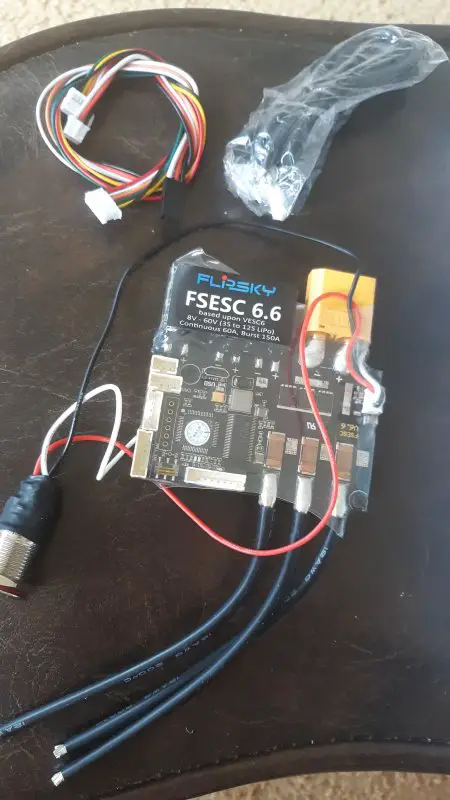

Bangood order update: ten day delivery on my Flipsky Vesc motor controller, so gold star on delivery this time.

Photos show the 3" x 3" x1" controller and a normal size high performance bike controller which is 9" x5" x 3" & weighs 5 lbs. & this compared to 5 oz. The small controller is fully programmable & is rated at 150 amp peak opposed to the big units 100 amp peak rating. Both have 60 amp continuous ratings at 60 volts. Intelligent programmable & small size with large capacity led me to try this controller that's been proven on all manner or motor driven devices even golf carts and industrial robots

Rick C.

Photos show the 3" x 3" x1" controller and a normal size high performance bike controller which is 9" x5" x 3" & weighs 5 lbs. & this compared to 5 oz. The small controller is fully programmable & is rated at 150 amp peak opposed to the big units 100 amp peak rating. Both have 60 amp continuous ratings at 60 volts. Intelligent programmable & small size with large capacity led me to try this controller that's been proven on all manner or motor driven devices even golf carts and industrial robots

Rick C.

Tom from Rubicon

Well-Known Member

Programable with a PLC?

Tom

Tom

indian22

Well-Known Member

Tom it's open source software so a ton of stuff and design tweaks are available. Primarily geared to Microsoft & Android.though I seem to recall seeing something for Mac

This design has a lot of developers & the Flipsky is just one of better known products out there

They have several models and also a lineup of compatible motors. The controllers are either for single or dual motor configurations. The controller I chose is for single motor only.

Not many e bike builders using this setup on YouTube and there may good reason on the motor but the controller will certainly work on a huge range of brushless DC motors. The one I have is good on ANY voltage between 8v. & 60 v. & this opens the door to many possibilites. Has both 3.3 &5 volt outputs on the board for accessory power phone charging, lights etc.

I'll update as I test, the good or bad, this post isn't a recommendation for any part of this setup; just a heads up to my build progress.

Rick C.

This design has a lot of developers & the Flipsky is just one of better known products out there

They have several models and also a lineup of compatible motors. The controllers are either for single or dual motor configurations. The controller I chose is for single motor only.

Not many e bike builders using this setup on YouTube and there may good reason on the motor but the controller will certainly work on a huge range of brushless DC motors. The one I have is good on ANY voltage between 8v. & 60 v. & this opens the door to many possibilites. Has both 3.3 &5 volt outputs on the board for accessory power phone charging, lights etc.

I'll update as I test, the good or bad, this post isn't a recommendation for any part of this setup; just a heads up to my build progress.

Rick C.

indian22

Well-Known Member

Interesting design feature of the motor is that except for the output shaft/motor support side the whole housing can affair rotates as well as opposite motor end cap. This allows for a pulley, prop or sprocket to be mounted on one or the other end of the motor or using both ends simultaneously for output. Also the surface of the spinning housing can be used with a friction drive for output. This gives triple output capabilities to each motor & each output type could have it's own drive train dedicated to a given task. Adding a second motor with its s own unique set of drive trains adds to complex tasking aided by separate motor controllers for specific application parameters.

For me I just want to power e bikes, but for industrial design guys this stuff is really simplifying reaching project goals without breaking budgets.

I will only be using the 10mm output shaft for my drive output.

Rick C.

For me I just want to power e bikes, but for industrial design guys this stuff is really simplifying reaching project goals without breaking budgets.

I will only be using the 10mm output shaft for my drive output.

Rick C.

indian22

Well-Known Member

I've a wireless throttle control on order which will eliminate some wiring used for motor braking and throttle as well. Though I'm using a 160mm disc on the front & coaster on the rear; the motor braking is ferocious on these motors, adding an amazing amount of braking. While I regard braking regeneration to the battery as a joke on e bicycles, almost worthless, but the added braking, that's a real deal.Interesting design feature of the motor is that except for the output shaft/motor support side the whole housing can affair rotates as well as opposite motor end cap. This allows for a pulley, prop or sprocket to be mounted on one or the other end of the motor or using both ends simultaneously for output. Also the surface of the spinning housing can be used with a friction drive for output. This gives triple output capabilities to each motor & each output type could have it's own drive train dedicated to a given task. Adding a second motor with its s own unique set of drive trains adds to complex tasking aided by separate motor controllers for specific application parameters.

For me I just want to power e bikes, but for industrial design guys this stuff is really simplifying reaching project goals without breaking budgets.

I will only be using the 10mm output shaft for my drive output.

Rick C.

View attachment 107859View attachment 107860

Though I continue to build using working pedal drive trains & utilizing mostly coaster or drum rear brakes. I do so for vintage motobicycle design concessions...for appearance & feel not performance. This electric powered bike will not, however, pedal without use of electric assist, unless the motor drive chain is removed. If the battery goes flat during an outing a rider can still easily pedal home by removing the chain. I chose motor braking over freewheeling on the motor drive train. Of course if I pedal under motor power that effort still produces as much assist as I am willing to induce.

My retro design goal is to maintain a vintage appearance and ride feel while using electric power. One thing I do miss is the sound of a gas motor, but I'm adjusting quickly to that loss.

Rick C.