indian22

Well-Known Member

I'm humbled Pete, thanks. I'd suggest others to do a lot more layout work than I did prior to building most anything. Not doing the primary design work has arisen to bite me rear several times already! Tolerances lol, fractional at best, except at run out. if it rotates it's quite close. One offs do allow for a bit of free style interpretation though I try not to get carried away with myself. A really key element that I try to keep in mind is the truly late 19th. century nature of these motors; quite agricultural/industrial fit and finish...though at times sprinkled with whimsical details. Fittings and tubing of that early era were straight out of the bins, typical hardware store items. Parts a plumber would have in his kit. That's what I attempt to keep mind as I build, that and not to over finish the motor case, always leaving some "age" on it along the way. Part of the charm of classic motor vehicles is they've survived the ages and I do my best to capture some of that age in most of my builds. What works for me is a bike that looks old & well ridden. but was carefully maintained over the decades. I'd say three years of riding in all types of weather completes the faux patina I initially apply to hurry things along, nature does great work on metal in that regard.

Doing with basic hand tools is a throw back to my youth, but even then I managed to get a lot of work done by area blacksmiths, welders and machine shops and learn along the way. I do miss my machine shop, but I'm pretty certain I get as much or more satisfaction from the process of building mostly by hand. Not so much that I didn't think twice about utilizing an automated plasma table to cut the myriad fins and side plates for this motor case. Great savings in time and effort, though turning steel cylinders would have been more efficient and quicker on a lathe. I didn't have access to a machine with the necessary size to do so myself and didn't want to farm it out.

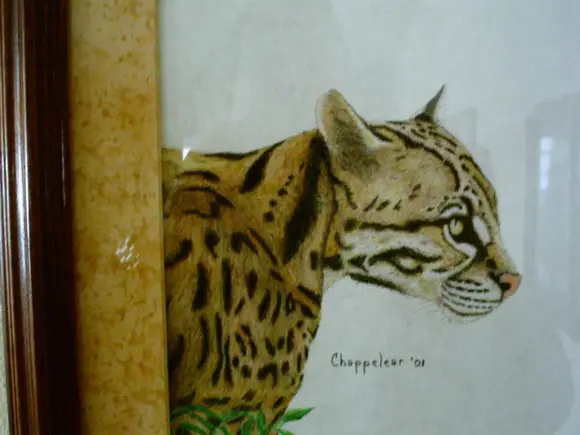

Before my eyes started to fail I painted wildlife (detail of an Ocelot included) that I'd encountered in my various travels. Art is important to me. I've also published a rather long novel and a couple of technical works as well.

Art & the search for first hand knowledge of a topic are two of the reasons, Pete, that I'm entranced by your travels to learn more of early rail equipage and the resulting exquisite rail miniatures you've created. The art & precision shows in your bikes and autos as well. They are great motivators to us all!

Rick C.

Doing with basic hand tools is a throw back to my youth, but even then I managed to get a lot of work done by area blacksmiths, welders and machine shops and learn along the way. I do miss my machine shop, but I'm pretty certain I get as much or more satisfaction from the process of building mostly by hand. Not so much that I didn't think twice about utilizing an automated plasma table to cut the myriad fins and side plates for this motor case. Great savings in time and effort, though turning steel cylinders would have been more efficient and quicker on a lathe. I didn't have access to a machine with the necessary size to do so myself and didn't want to farm it out.

Before my eyes started to fail I painted wildlife (detail of an Ocelot included) that I'd encountered in my various travels. Art is important to me. I've also published a rather long novel and a couple of technical works as well.

Art & the search for first hand knowledge of a topic are two of the reasons, Pete, that I'm entranced by your travels to learn more of early rail equipage and the resulting exquisite rail miniatures you've created. The art & precision shows in your bikes and autos as well. They are great motivators to us all!

Rick C.