The_Aleman

Active Member

<removed out of protest to certain "staff" practices in this forum.>

Last edited:

Walmart - it looks like a can of fixaflat, but as big as a little Red Bull drink.

Ultra Bike Tire Sealer and Inflater 4.96

Here's something I figured out as I was going at it... a long twist tie is a great thing for helping to thread the chain through the motor.. tie it firmly to the first link an feed the tie through where the drive sprocket is. When it comes out you can pull (gently) on it as you try to rotate the drive sprocket to pull the chain through. With a loop in the free end you can slide a screwdriver through the tie to pull on. The same twist tie is also great for helping pull the chain together (and hold it together) to find out where to break the chain and in keeping the ends close when putting in a master link.

I keep a few long ties stuffed in the tool kit in case I have to reconnect the chain away from the garage, or ever have to tie down a cable or anything.

I've also found a twist tie is great for holding the extra length of the clutch cable against the clutch arm so it doesn't stab me in the leg with every pass.

Check the garden section of your local hardware etc store for the gardening wire-tie that comes as a coil for tying up your plants. Handy stuff for a couple of bucks.

You could also use the "spark plug" tool that came with the kit. It fits the drive sprocket bolt so insert the chain and use a screwdriver to turn the sprocket.

I went to Advanced auto and asked the guy working to point me to the direction of the cork style gasket material he asked me what it was for I said I'm using it on my intake manifold and my exhaust manifold. You can not use it on your exhaust manifold .I said OK what ever you say Then the guy says I'm not selling this to you.and takes it back . So the next day I sent my fiance in to get the same stuff I could have easily went to Auto zone but this was personal. So he asked her whats it for she said what? What are you using it for, she said to be honest it isn't any of your business what I'm using it for. Keep in mind this guy is just plain rude we are not rude folks but the way this guy asks "What are you using it on"? If Id a seen the problems coming I'd have said I ran out of cheese , & given him the Mel Gibson Crazy look from L.W.1Guys

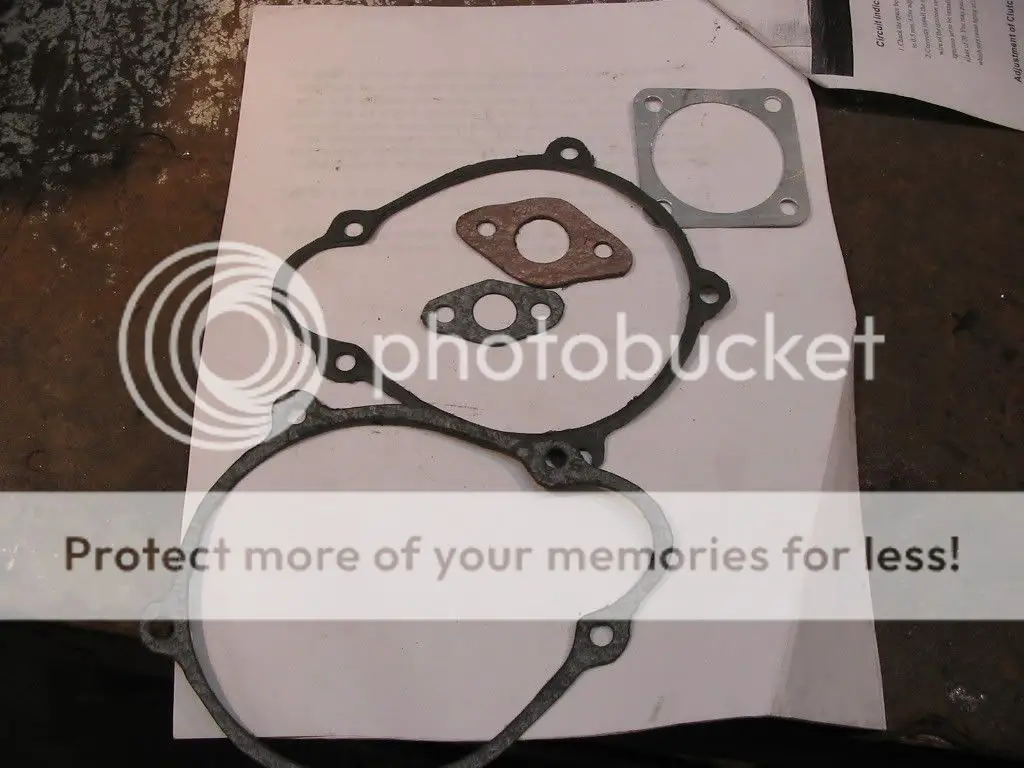

When you first get your engine take the time to make good gaskets use the kits gasket as a pattern and use your home made ones. mostly the side covers,intake and exhaust will be the ones to make here's an example.

Problem:

When i pedal and pop the clutch to start the engine, the back wheel doesn't lock up like it use to. like, when i move the bike slowly with the clutch lever pulled in, the back wheel moves freely, but when i let go(the back wheel USE to lock up(im guessing thats proper working condition cause that always worked for me)) the wheel will semi-lock up but will still spin rather easy. i think it has something to do with the clutch, i've tried re-adjusting the clutch cable and arm but to no avail. If no-one can help me with this, im prolly gonna end up scrappin my engine out

Problem:

When i pedal and pop the clutch to start the engine, the back wheel doesn't lock up like it use to. like, when i move the bike slowly with the clutch lever pulled in, the back wheel moves freely, but when i let go(the back wheel USE to lock up(im guessing thats proper working condition cause that always worked for me)) the wheel will semi-lock up but will still spin rather easy. i think it has something to do with the clutch, i've tried re-adjusting the clutch cable and arm but to no avail. If no-one can help me with this, im prolly gonna end up scrappin my engine out

I cant see the dual pull as feasable, too tedious an adjustment to get the right pull front and rear.