Norman

LORD VADER Moderator

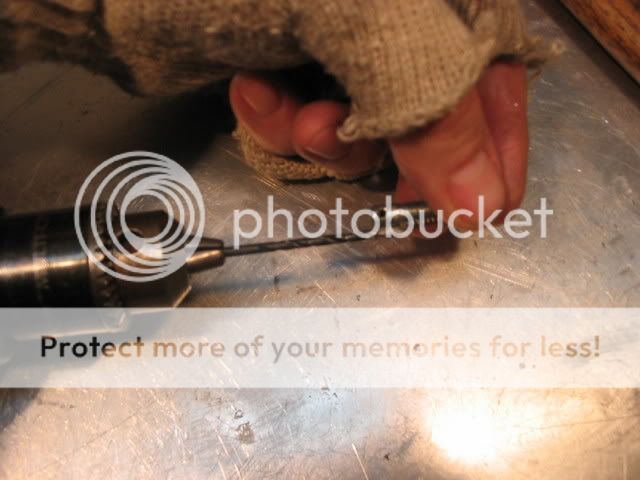

I'm making a simple cable end that anyone of you can make and carry on your bike for emergency road side repairs but you will have to carry tools just for this thing more stuff to loose, Alot of times the cable that breaks will be useless even if you have the end but I thought I'd show you how to and get you all to thinking. If you don't carry an extra cable, just carry the end or for what ever reason. You can skip the threading and drilling for the pinch bolt and silver solder the end on if you want. I don't recommend using regular solder as it will not hold as well if at all. I used a normal 1/4" steel bolt, you can do it that way or use brass for the body. I used a small 6-32" Allen set screw as you can get more torque on it a machine screw might work but then again if you slip tightening it you might stab your hand with the screw driver. Anyway here we go.