You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

chain tension help

- Thread starter paul

- Start date

MotorbikeMike

Dealer

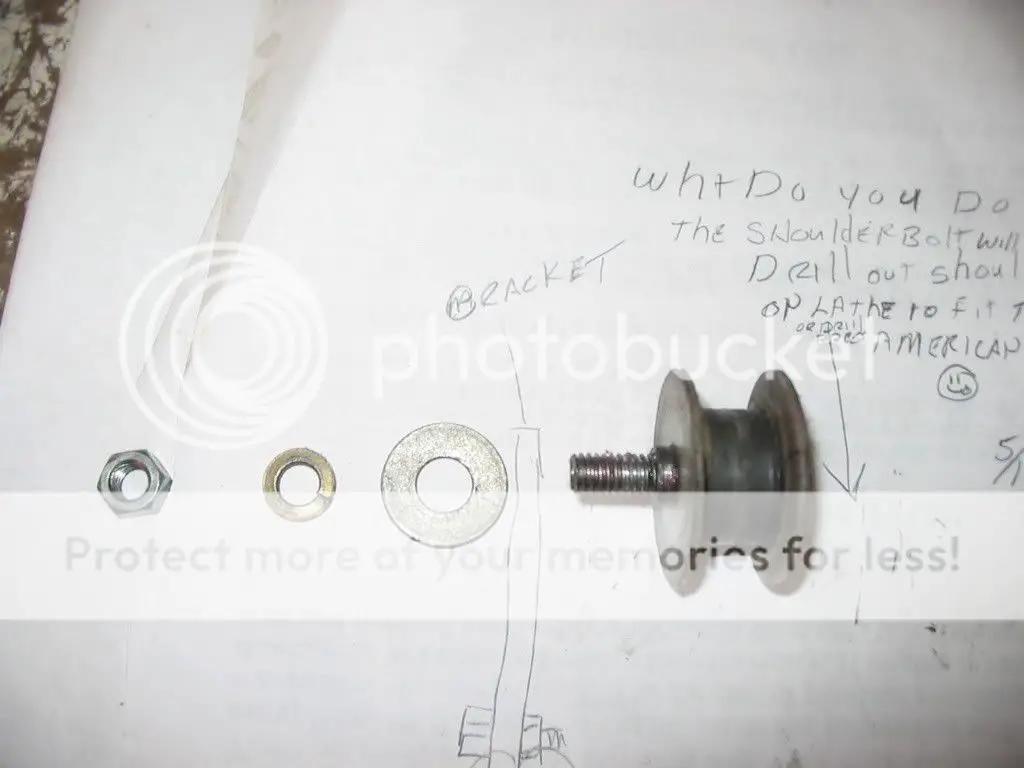

Hi Wayde, it's been my experiance that half-links are weak and problematic. This is wht I developed the "T-Shirt".

Tine will tell on your bike, but I've had half-links fail even on the people chain, so I will never trust one on an engine again.

Mike

Tine will tell on your bike, but I've had half-links fail even on the people chain, so I will never trust one on an engine again.

Mike

Pablo

Master Bike Builder & Forum Sponsor

All I can say is tensioning the chain is the biggest headache so far.....I don't mind taking links out (kinda fun really) but it just seems like I can't get the tension just right and the tensioner seems to interfere more than it helps. Also it seems like my sprocket has a small side to side wobble (NOT up and down alignment). Maybe one side is tighter than the other......

deacon

minor bike philosopher

On mine which I probably did wrong. I measured the distance from the sprocket to the first spoke one both sides of the nut. i tightened the nuts till the distance was the same for all of them. Not sure if that would help. but yeah it was a pain for me and i am never sure I have it right.

Andyinchville1

Manufacturer/Dealer

Short of mounting the sprocket on a grubee hub or mounting a custom(ized) sprocket to the disc brake hub it is very difficult or nearly impossible to have a perfectly mounted sprocket with no side to side or up an down wobble....You can get very close tho or at least close enough..

Andrew

Andrew

Pablo

Master Bike Builder & Forum Sponsor

...... I measured the distance from the sprocket to the first spoke one both sides of the nut. i tightened the nuts till the distance was the same for all of them. Not sure if that would help.........

Actually that is a good idea!! Don't know why I didn't think of measuring it other than lack of O2 to the brain

Norman

LORD VADER Moderator

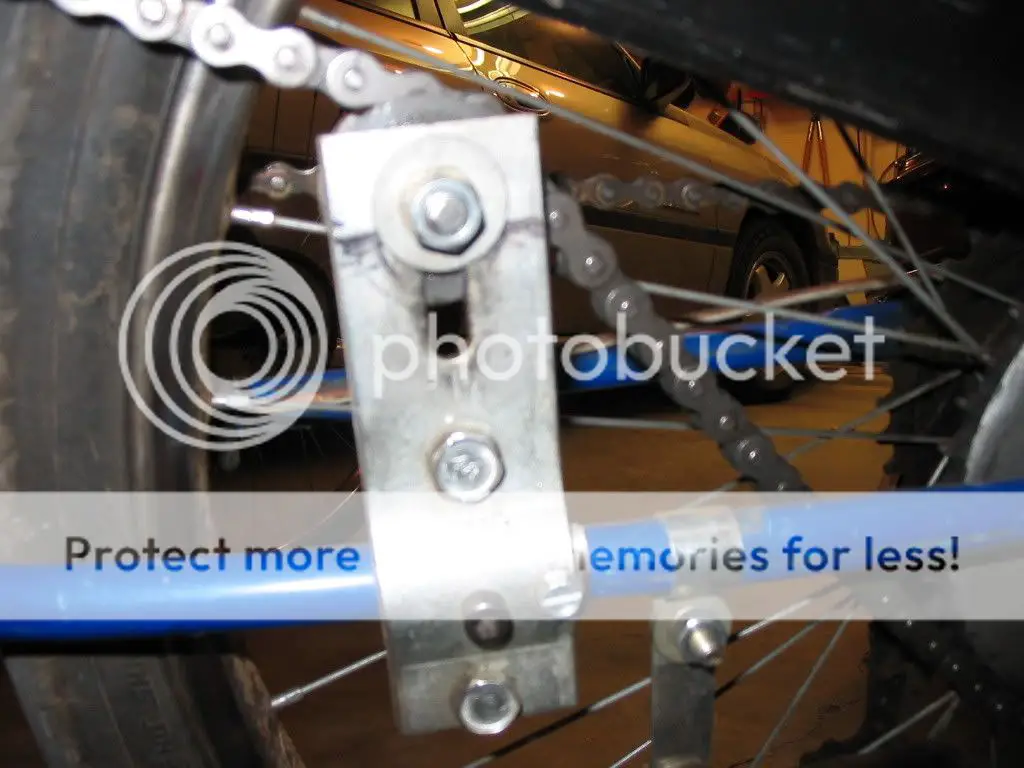

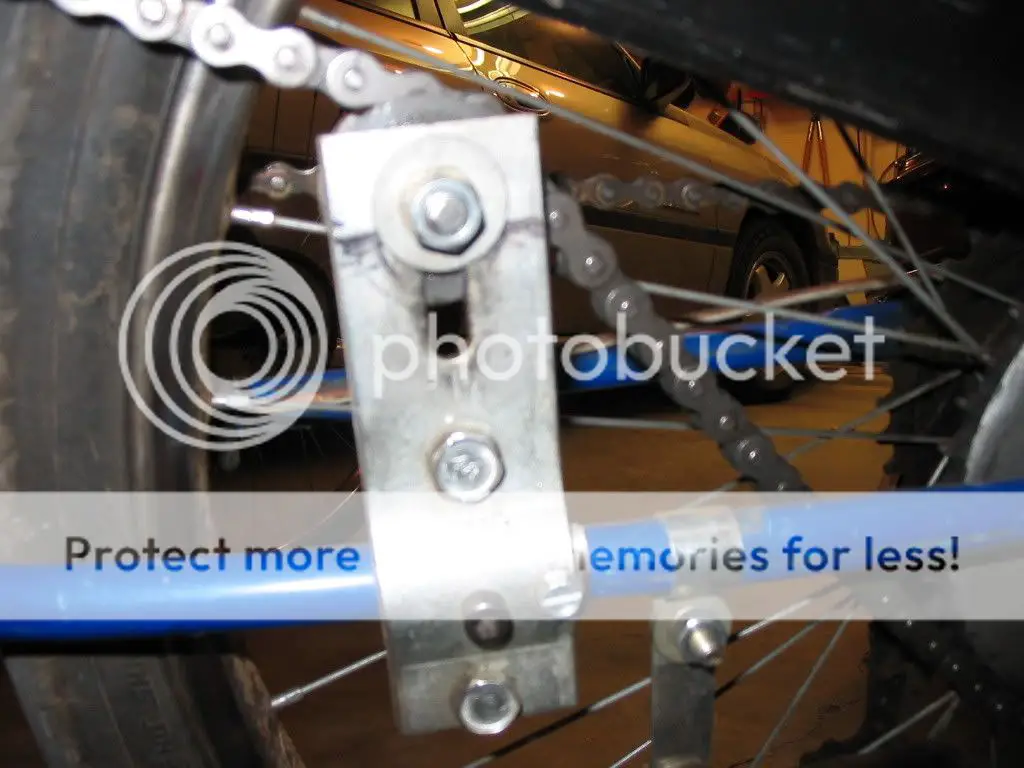

here it is all back on and you can see at the top limit. Note the sheet metal screw and socket head bolt these are to stop the bracket from rotating into the spokes . The socket head bolt hole is tapped in the frame and drilled a hair over size on the bracket. I also have shims under the bracket as the frame dia. wasn't large enough and the bracket wallered around on the frame.

Norman

LORD VADER Moderator

here the tensioner mount is a little different and while building the bike I built up the area where the tensioner mounts by welding on donated frame material form a donor bike. You might be able to use a propane torch and solder and do the same thing if you don't have a welder. The solder to use would be the stuff plumbers use to solder together metal ducting.

Norman

LORD VADER Moderator

another way of breaking the chain with a punch (better to use a nontapered punch )and hammer. I use my vice as a back up opened only far enough so the pins will come out. you can also use a block of wood with small holes drilled to receive the pins as they are knocked out there's many ways to do this etc.