Beachcomber

Well-Known Member

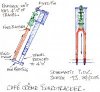

Good news on the intake manifold .......... I took the OEM unit off the engine and found out under all the rubber crap - it's alloy ! I have got an original 1 1/4" SU alloy intake flange - bingo, no need to get a manifold fabricated I just need a simple swan neck bend fron the carb to the original manifold. Not often something just drops into place.

I also priced up the rear axle mount plates ...... HOW MUCKIN FUTCH !!! It's only £35 dearer to get a complete rear end tubing kit together with axle plates !

I also priced up the rear axle mount plates ...... HOW MUCKIN FUTCH !!! It's only £35 dearer to get a complete rear end tubing kit together with axle plates !