You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bike builders that have machine tools/shops

- Thread starter Tom from Rubicon

- Start date

indian22

Well-Known Member

Poor engineering on my part Rick,

Side by side 6-32's would have left some meat in the cross sections, and adequate clamping force

This tool box was going nowhere.

Dan's tool box per my numbers, left a 1/16" gap between tool box and Flyer gas tank. That I took up by cutting a section of bicycle inner tube into halves to dynamically tension and balance the side to side spacing.

My ride today, I never once looked at the hose clamps.

On starting the Sportsman Flyer, the tool box with closure on the right hand side made for quick stowage of the pull start rope.

Early bikes often featured common bin hardware and I don't think the hose clamp detracts at all from the bikes vintage look, perhaps just the opposite.

Rick C.

Heck, I'm going to use a mill jig on my drill press so I'll share the results of that when it happens. I'm not too sure what you guys are talking about but I'll progress in some way.

I tried that Ralph and I'm sorry to say it, but it didn't work. The issue is drill presses have somewhat unique bearings in that they're designed to be loaded from the side. Which would be top and bottom in a drill press.

Lathes and mills have angular contact bearings that can take a load in both directions. Axial and radial.

Common bearings are radial.

There is still a lot of benefit to be derived from an XY table on a drill press tho. One thing is you can do a very accurate layout for the placement of holes. If you need 2 holes to be 2" apart. Or 4 holes on a 2' square pattern. It'll still be handy to have. We never have enough tools!

indian22

Well-Known Member

Traded a guy a few parts and a little cash for an unused 7"x14" lathe today, no tools with it and dang sure not what I'm accustomed to, but it was close to being a freebie and won't take up much room. People when laid off start selling stuff.

I'm now on the lookout for a small mill....

Rick C.

I'm now on the lookout for a small mill....

Rick C.

Tony01

Well-Known Member

Here’s a Big A$S surface plate. Useful for a variety of uses like stuff that doesn’t fit in a vise easily. Of course this is a massive one and you can make a small one from any piece of plate.

Mount your head to it. With a thick enough plate you can drill and tap holes to use toe clamps or just bolts to mount in your stuff. If I had a setup I’d put the head on the angle plate and use a saw like this. Only turn it around 90deg along z from this pic and use your y axis for depth of cut control, cut side to side with top of head facing you.

Mount your head to it. With a thick enough plate you can drill and tap holes to use toe clamps or just bolts to mount in your stuff. If I had a setup I’d put the head on the angle plate and use a saw like this. Only turn it around 90deg along z from this pic and use your y axis for depth of cut control, cut side to side with top of head facing you.

Attachments

Tom from Rubicon

Well-Known Member

Tony, we ain't got no stinking CNC

Tom

Tom

MEASURE TWICE

Well-Known Member

Hey, idea, replace the motor temporarily on the drill press somehow with that old router lying around. There ya go!

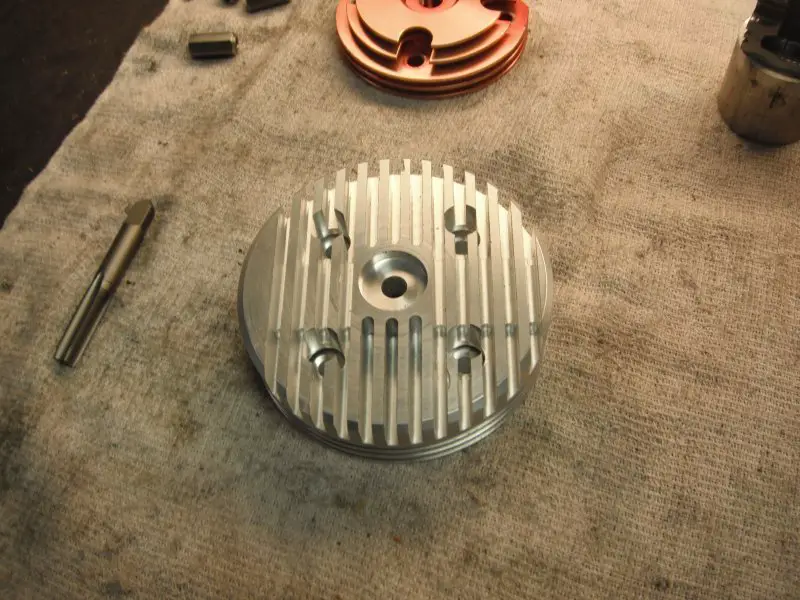

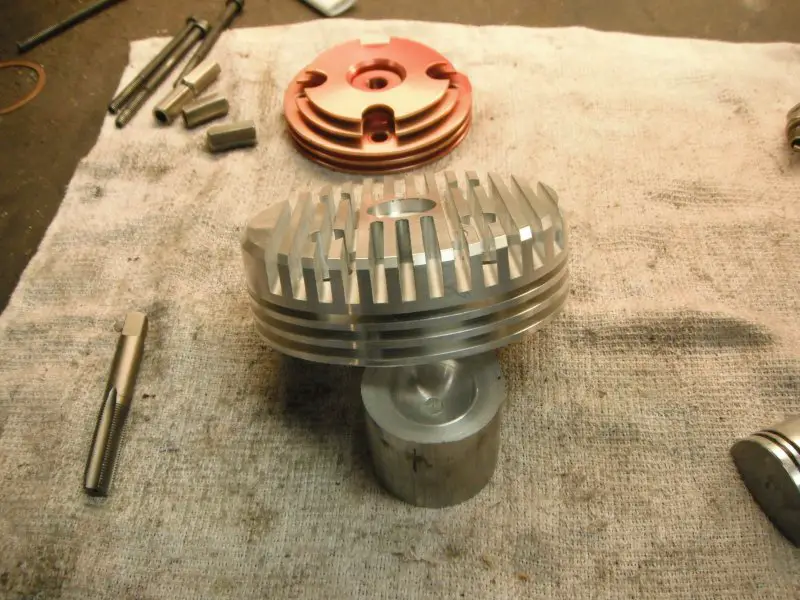

I've been nibblin' away at this cylinder head. 10 thou at a time and it ain't all that bad. I get into a zone I call being "One with the Machine" and the time just flies by. What I have to be real careful of is getting zoned out and cutting too far!

But I do have some issues to still work out.

One is it's missing a slot. I couldn't reach it! The Y axis bottomed out before I could get there. I'm gonna have to clean all the aluminum snow off the mill and remount the mill vise to get that one.

At .140 wide the fins are too thick too.

The fins on that head in the background are .090. The cast fins on the cylinder are only .050. So I'm calling this just a rough cut. It still needs some trimming.

Something I figured out along the way is the .155 endmill I used is way too long. It has a 1' reach and I only need a half! I'll betcha a shorter cutter would've got me a lot closer to the .030 cuts Tony was talking about ...

But so far so good. I'm learning.

But I do have some issues to still work out.

One is it's missing a slot. I couldn't reach it! The Y axis bottomed out before I could get there. I'm gonna have to clean all the aluminum snow off the mill and remount the mill vise to get that one.

At .140 wide the fins are too thick too.

The fins on that head in the background are .090. The cast fins on the cylinder are only .050. So I'm calling this just a rough cut. It still needs some trimming.

Something I figured out along the way is the .155 endmill I used is way too long. It has a 1' reach and I only need a half! I'll betcha a shorter cutter would've got me a lot closer to the .030 cuts Tony was talking about ...

But so far so good. I'm learning.

Tom from Rubicon

Well-Known Member

Bill,

Don't suppose you have any angle end mills? By angling the fins instead of thinning them a larger heat sink area

https://www.ebay.com/itm/6-degree-t...119558?hash=item2ce6493986:g:hagAAOSwpLxceAQE

Tom

Don't suppose you have any angle end mills? By angling the fins instead of thinning them a larger heat sink area

https://www.ebay.com/itm/6-degree-t...119558?hash=item2ce6493986:g:hagAAOSwpLxceAQE

Tom

Bill,

Don't suppose you have any angle end mills? By angling the fins instead of thinning them a larger heat sink area

https://www.ebay.com/itm/6-degree-t...119558?hash=item2ce6493986:g:hagAAOSwpLxceAQE

Tom

I never thought of it and that's a helluva good idea! That'll look cool . I'll look thru what I got 1st and draw up what the angled mill you linked might look like, but one way or another this is gonna happen.

Tom from Rubicon

Well-Known Member

Sorry I didn't Trig. it out for you Bill, lazy I am but you spec'd .140 fin width but not height. Just looking at it guessing 7/16"?

Tom

Tom

Tom from Rubicon

Well-Known Member

Rick sorry I didn't give you a reply to #745. I hope you don't blame me  for adding to your inventory..

for adding to your inventory..

Be careful and don't cut your fingers off.

But I'm with you brother, having to get another person to do what you want done now is not always going to happen. And keeping your hand in is good for the brain I hope.

Tom

Be careful and don't cut your fingers off.

But I'm with you brother, having to get another person to do what you want done now is not always going to happen. And keeping your hand in is good for the brain I hope.

Tom

indian22

Well-Known Member

Rick sorry I didn't give you a reply to #745. I hope you don't blame mefor adding to your inventory..

Be careful and don't cut your fingers off.

But I'm with you brother, having to get another person to do what you want done now is not always going to happen. And keeping your hand in is good for the brain I hope.

Tom

Tom with everything that's going on I'm concentrating on the basics & hopefully I won't let the small aggravations of life get blown out of proportion. Delays on orders are just inconvenient. I'm also finding myself spending more time sourcing items that normally would be available which is, again, just inconvenient & not life altering...unless I allow it to be. I suppose I should just be thankful that commerce is still in motion.

Continue to take care.

Rick C.

Tom from Rubicon

Well-Known Member

All I did today Rick, is get a slab of pork ribs split and laid on a roasting rack of my big SS roaster. Put the lid on and set the oven @ 250F and got busy making my favorite BBQ sauce. Ribs in at noon, sauce made by 2:30 and started ladling it on. Many turnings and saucing's. Went to turn the ribs at 6:30 and wouldn't turn over in one piece.

I bet you wish you were here, and Mona's coleslaw …….

Night guys, Bon Appetit

Tom

I bet you wish you were here, and Mona's coleslaw …….

Night guys, Bon Appetit

Tom

Greg58

Well-Known Member

Guys my father in law has been after me far a while to come get a drill press out of his way, he’s 80 and partially disabled. The drill press is too large for the table he had it on so I picked it up the other day, I’m going to swap my 8” for it, he’ll have a smaller press and can still build birdhouses.

Sorry I didn't Trig. it out for you Bill, lazy I am but you spec'd .140 fin width but not height. Just looking at it guessing 7/16"?

Tom

I bought that 6 degree cutter Tom. I drew up just fine and with "experienced eyeballs" like yours trig isn't necessary.

Supposed to be here Saturday. I can hardly wait ...

indian22

Well-Known Member

All I did today Rick, is get a slab of pork ribs split and laid on a roasting rack of my big SS roaster. Put the lid on and set the oven @ 250F and got busy making my favorite BBQ sauce. Ribs in at noon, sauce made by 2:30 and started ladling it on. Many turnings and saucing's. Went to turn the ribs at 6:30 and wouldn't turn over in one piece.

I bet you wish you were here, and Mona's coleslaw …….

Night guys, Bon Appetit

Tom

Ribs just rose to top of my to do list Tom. Thanks for helping me allocate my time wisely!

Rick C.