You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

79cc Sportsman Flyer build

- Thread starter Tom from Rubicon

- Start date

Tom from Rubicon

Well-Known Member

Wanted to remove the cast iron flywheel before any thing else got done.

It's in the way if I have to shorten the protrusion on the crankcase that supports governor axle.

The axel gets driven out leaving a hole in the crank case so I will drill the axel and governor bores with a letter C drill and tap 1/16- 27 NPT. I have plugs for both.

So I gotta get the flywheel off, socket wrench on the nut, Halder Supercraft dead blow, and I'm beating away. Nuthin.

Well that was yesterday, and I reviewed selected scenes of both AGK and ARC. I decided, I was driving the nut wrong way.

It happens even to a good man I am told. Back on the bench this afternoon. Wrench and hammer whacking away counter clock wise. Still nuthin.

Plan B. Couple of years ago I purchased a Porter Cable electric impact driver 1/2" drive. Weighs more than a small dog.

Pulled the trigger and off comes the nut, starter cup, and plastic fan. Small leap for mankind.

Nut back on the crank shaft to guard the crankshaft threads, I gave that nut some fierce licks with the Halder hammer.

Nuthin again, I got a trend going. So I breaks out the heavy artillery.

So I breaks out the heavy artillery.

Amazon.com: Estwing Special Edition Fireside Friend Axe - 14" Wood Splitting Maul with Forged Steel Construction & Genuine Leather Grip - EFF4SE: Home Improvement

Nice rap and the iron flywheel is off it's taper at last. Copper chisel and 4oz hammer free the woodruff key from the shaft.

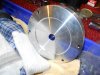

So I got this cast iron flywheel in one hand and this high toned CNC machined be all end all aluminum (Brits say different)

Flywheel in the other. Hmmm. Take them in the house to Grand Dads scale.

Cast iron was a smidgeon lighter than the 3lb ARC flywheel. Tempted to get in touch with ARC and ask WTF? Anyway.

Back to the shop. Took forever to find my Dykem Prussian Blue. Wasn't where it was supposed to BEER!

To me it a goodenoff fit I will not do the lap routine.

The 65 ft lb torque and keyed flywheel crankshaft assy. has my confidence. Besides there is a local car show May 15.

Some photos.

It's in the way if I have to shorten the protrusion on the crankcase that supports governor axle.

The axel gets driven out leaving a hole in the crank case so I will drill the axel and governor bores with a letter C drill and tap 1/16- 27 NPT. I have plugs for both.

So I gotta get the flywheel off, socket wrench on the nut, Halder Supercraft dead blow, and I'm beating away. Nuthin.

Well that was yesterday, and I reviewed selected scenes of both AGK and ARC. I decided, I was driving the nut wrong way.

It happens even to a good man I am told. Back on the bench this afternoon. Wrench and hammer whacking away counter clock wise. Still nuthin.

Plan B. Couple of years ago I purchased a Porter Cable electric impact driver 1/2" drive. Weighs more than a small dog.

Pulled the trigger and off comes the nut, starter cup, and plastic fan. Small leap for mankind.

Nut back on the crank shaft to guard the crankshaft threads, I gave that nut some fierce licks with the Halder hammer.

Nuthin again, I got a trend going.

So I breaks out the heavy artillery.

So I breaks out the heavy artillery.Amazon.com: Estwing Special Edition Fireside Friend Axe - 14" Wood Splitting Maul with Forged Steel Construction & Genuine Leather Grip - EFF4SE: Home Improvement

Nice rap and the iron flywheel is off it's taper at last. Copper chisel and 4oz hammer free the woodruff key from the shaft.

So I got this cast iron flywheel in one hand and this high toned CNC machined be all end all aluminum (Brits say different)

Flywheel in the other. Hmmm. Take them in the house to Grand Dads scale.

Cast iron was a smidgeon lighter than the 3lb ARC flywheel. Tempted to get in touch with ARC and ask WTF? Anyway.

Back to the shop. Took forever to find my Dykem Prussian Blue. Wasn't where it was supposed to BEER!

To me it a goodenoff fit I will not do the lap routine.

The 65 ft lb torque and keyed flywheel crankshaft assy. has my confidence. Besides there is a local car show May 15.

Some photos.

Attachments

Tom from Rubicon

Well-Known Member

Drilled letter C drill through both governor crankcase holes. The governor axel support hole is cast as boss like feature on the exterior of the crankcase, flywheel side. AGK recommends reducing the height it stands up off the exterior of the crankcase so as not to engage the flywheel. I found in my tooling a counterbore with a pilot matching the holes drilled.

Luck? I think so. The governor boss thusly was shortened by 3mm. There after both re-drilled bores were tapped 1/6-27.

Plugs installed. All of the above took one hour and one beer.

Still got a bit of cleaning crankcase wise. But that is it, I think. Next thing on this adventure is reassemble all I took apart.

A torqueing I will go, a torqueing will go.....

Therein is a problem. All the video's use those clicky preset torque wrenches.

Mine have either pointers or a dial. At my age (70) retooling reflects my Peter Pan syndrome.

I think I caught from a neighbor 60 years ago.

Opinions;

Stick with what I got or more to add to the auction when I croak? This will be fun.

Sabbath relegated to Spring yard work. It needs it.

Luck? I think so. The governor boss thusly was shortened by 3mm. There after both re-drilled bores were tapped 1/6-27.

Plugs installed. All of the above took one hour and one beer.

Still got a bit of cleaning crankcase wise. But that is it, I think. Next thing on this adventure is reassemble all I took apart.

A torqueing I will go, a torqueing will go.....

Therein is a problem. All the video's use those clicky preset torque wrenches.

Mine have either pointers or a dial. At my age (70) retooling reflects my Peter Pan syndrome.

I think I caught from a neighbor 60 years ago.

Opinions;

Stick with what I got or more to add to the auction when I croak? This will be fun.

Sabbath relegated to Spring yard work. It needs it.

Tom from Rubicon

Well-Known Member

Yard work sorta done. In the shop for about a beer. Primarily to seat the ARC flywheel on the crankshaft taper.

After cleaning out the Prussian Blue.

The stuff gets around like Bear $hit roofing tar.

Just drew up the flywheel mounting nut to firm, not torqued. There is about 1.5mm clearance now between the flywheel and the governor axel boss about 1.5mm. Torqueing the flywheel nut to 65 foot pounds will be the challenge.

ARC has a way of locking the crankshaft, from output side I need to investigate or use a strap wrench on the flywheel.

A strap wrench is locally $27. Used maybe once maybe? I have been thinking of other methods to secure the flywheel.

Tom

After cleaning out the Prussian Blue.

The stuff gets around like Bear $hit roofing tar.

Just drew up the flywheel mounting nut to firm, not torqued. There is about 1.5mm clearance now between the flywheel and the governor axel boss about 1.5mm. Torqueing the flywheel nut to 65 foot pounds will be the challenge.

ARC has a way of locking the crankshaft, from output side I need to investigate or use a strap wrench on the flywheel.

A strap wrench is locally $27. Used maybe once maybe? I have been thinking of other methods to secure the flywheel.

Tom

Tom from Rubicon

Well-Known Member

Plan B again, again. So ARC has a in house made crankshaft locking tool used when torqueing a flywheel nut.

I gave serious thought to making one, but unless I do more than one of these up grades it is pointless and my heirs will have no clue and dumpster my work. So KISS. Many times in my life immobilizing a precision round surface was necessary.

Using copper or aluminum of sufficient thickness to guard the jaws of Vise-Grips being the most common griping tool.

So once more eureka!

3/4" copper water tubing walls are thick and grippy. So I turned the engine crankshaft key way to face the moving jaw of the Bridgeport vise.

Sleeved the 2" x 5/8" dia. key slot area with copper tubing. Orienting the shaft keyway into a vise jaw for maxim grip.

Torqueing to 46 foot pounds was Duck Soup. Crankshaft never budged. KISS wins again.

Tom

I gave serious thought to making one, but unless I do more than one of these up grades it is pointless and my heirs will have no clue and dumpster my work. So KISS. Many times in my life immobilizing a precision round surface was necessary.

Using copper or aluminum of sufficient thickness to guard the jaws of Vise-Grips being the most common griping tool.

So once more eureka!

3/4" copper water tubing walls are thick and grippy. So I turned the engine crankshaft key way to face the moving jaw of the Bridgeport vise.

Sleeved the 2" x 5/8" dia. key slot area with copper tubing. Orienting the shaft keyway into a vise jaw for maxim grip.

Torqueing to 46 foot pounds was Duck Soup. Crankshaft never budged. KISS wins again.

Tom

Attachments

Nightster

Well-Known Member

Awesome Tom, Copper FTW !!!Plan B again, again. So the ARC has a in house made crankshaft locking tool used when torqueing a flywheel nut.

I gave serious thought to making one, but unless I do more than one of these up grades it is pointless and my heirs will have no clue and dumpster my work. So KISS. Many times in my life immobilizing a precision round surface was necessary.

Using copper or aluminum of sufficient thickness to guard the jaws of Vise-Grips being the most common griping tool.

So once more eureka!

3/4" copper water tubing walls are thick and grippy. So I turned the engine crankshaft key way to face the moving jaw of the Bridgeport vise.

Sleeved the 2" x 5/8" dia. key slot area with copper tubing. Orienting the shaft keyway into a vise jaw for maxim grip.

Torqueing to 46 foot pounds was Duck Soup. Crankshaft never budged. KISS wins again.

Tom

Tom from Rubicon

Well-Known Member

When in doubt Danny, think first and KISS.

Tom

Tom

Nightster

Well-Known Member

Most of the time thinking it out really helps. And I agree, KISS!When in doubt Danny, think first and KISS.

Tom

Tom from Rubicon

Well-Known Member

So the ARC Racing flywheel is torqued to spec. Time to lace this engine up. Without the video's of AGK and ARC Racing, I most likely would farmed the work out.

Thing I learned from AGK. Don't mangle valve seats so you have to recut them. My solution is patent pending, Just kidding.

ARC doesn't mess around. But if you want to go past their keyed timing you will have to lap the flywheel taper to match the crank shaft taper. As I did no lapping of the crankshaft flywheel taper, when drawn up, to the 46 ft lbs all clearances were in the + 1mm range. Empirical data is wanting.

Thing I learned from AGK. Don't mangle valve seats so you have to recut them. My solution is patent pending, Just kidding.

ARC doesn't mess around. But if you want to go past their keyed timing you will have to lap the flywheel taper to match the crank shaft taper. As I did no lapping of the crankshaft flywheel taper, when drawn up, to the 46 ft lbs all clearances were in the + 1mm range. Empirical data is wanting.

Tom from Rubicon

Well-Known Member

Nightster

Well-Known Member

Well that sucksSpring and Mother Nature and round snow.

Tom from Rubicon

Well-Known Member

Nah! There is a saying about a robins, they have to have snow in their tail three time before warm Spring weather comes.Well that sucks

It has flurried off and on all day lower thirty's tomorrow will be mid fifties. Thank-you Robins.

Tom

Nightster

Well-Known Member

I hear you, but we don’t have that saying in Texas, lol.Nah! There is a saying about a robins, they have to have snow in their tail three time before warm Spring weather comes.

It has flurried off and on all day lower thirty's tomorrow will be mid fifties. Thank-you Robins.

Tom

however, in 2-3 months it will be 99° here

Tom from Rubicon

Well-Known Member

Eskers are going to have to wait Pete, too bloody cold, and besides I have misplaces the engine side cover bolts.

How? Senior moment? Beer?

Peterson's law of lost things, "If you can't find it is underneath something".

Foolish of me to have not copyrighted such wisdom.

And I did look under everything, nope. Found some loose coinage in my pockets.

Got me one coming Flex-Hone BC 3/4" Honing Tool: Amazon.com: Industrial & Scientific

Intake and exhaust ports are not up to my standards, (Critiquing my own work)

A new forumite has inquired about engaging

Peterson Precision to do for him what I have done for myself. Port, polish, deck the head, and remove governor.

Flex-Honing the ports will distinguish my work.

Another thought, steel masking shields to obviate the worry of damaged valve seats, while cleaning up combustion chamber. Gonna do it.

Tom

How? Senior moment? Beer?

Peterson's law of lost things, "If you can't find it is underneath something".

Foolish of me to have not copyrighted such wisdom.

And I did look under everything, nope. Found some loose coinage in my pockets.

Got me one coming Flex-Hone BC 3/4" Honing Tool: Amazon.com: Industrial & Scientific

Intake and exhaust ports are not up to my standards, (Critiquing my own work)

A new forumite has inquired about engaging

Peterson Precision to do for him what I have done for myself. Port, polish, deck the head, and remove governor.

Flex-Honing the ports will distinguish my work.

Another thought, steel masking shields to obviate the worry of damaged valve seats, while cleaning up combustion chamber. Gonna do it.

Tom

Tom from Rubicon

Well-Known Member

Yeah, come Summer time I covet not your weather Danny.

Nightster

Well-Known Member

Nor do I, since I work in itYeah, come Summer time I covet not your weather Danny.

Tom from Rubicon

Well-Known Member

Not much done today, Trip to Ace for six M6x1x30 flange head bolts, verified timing marks one more time, and slipped the side cover on.

As per AGK, side cover bolts are torqued 96 inch pounds.

So I did the best I could, my In lb - Km torque wrench is a fifty year old Monkey Ward analog. Like beam and pointer kind.

Felt right when the pointer hovered at 100 In lb with my reading glasses on.

I would have finished the close up, but I am holding out for the 320 gr Flex-Hone to arrive.

Nothing like a proper cross hatch surface.

Tom

As per AGK, side cover bolts are torqued 96 inch pounds.

So I did the best I could, my In lb - Km torque wrench is a fifty year old Monkey Ward analog. Like beam and pointer kind.

Felt right when the pointer hovered at 100 In lb with my reading glasses on.

I would have finished the close up, but I am holding out for the 320 gr Flex-Hone to arrive.

Nothing like a proper cross hatch surface.

Tom

Tom from Rubicon

Well-Known Member

So today I got my first clickety clickety torque wrench. One you preset for a desired torque and clicks at desired torque load.

I know they have a proper name, but I am fond of onomatopoeia. Being 3/8" the range is only 10 to 80 ft lbs.

I do have from my Harley building days a 1/2" drive dial indicated torque wrench. Insane range of 0 to 500 ft lbs.

Flex- Hone not expected until Monday.

Foot note: laundry soap is rather caustic and darkens aluminum.

Dish soap does not and cuts petroleum products better.

Tom

I know they have a proper name, but I am fond of onomatopoeia. Being 3/8" the range is only 10 to 80 ft lbs.

I do have from my Harley building days a 1/2" drive dial indicated torque wrench. Insane range of 0 to 500 ft lbs.

Flex- Hone not expected until Monday.

Foot note: laundry soap is rather caustic and darkens aluminum.

Dish soap does not and cuts petroleum products better.

Tom