Ryoskate

New Member

Just came across this thread..... real nice... the seat custom your doing way cool!

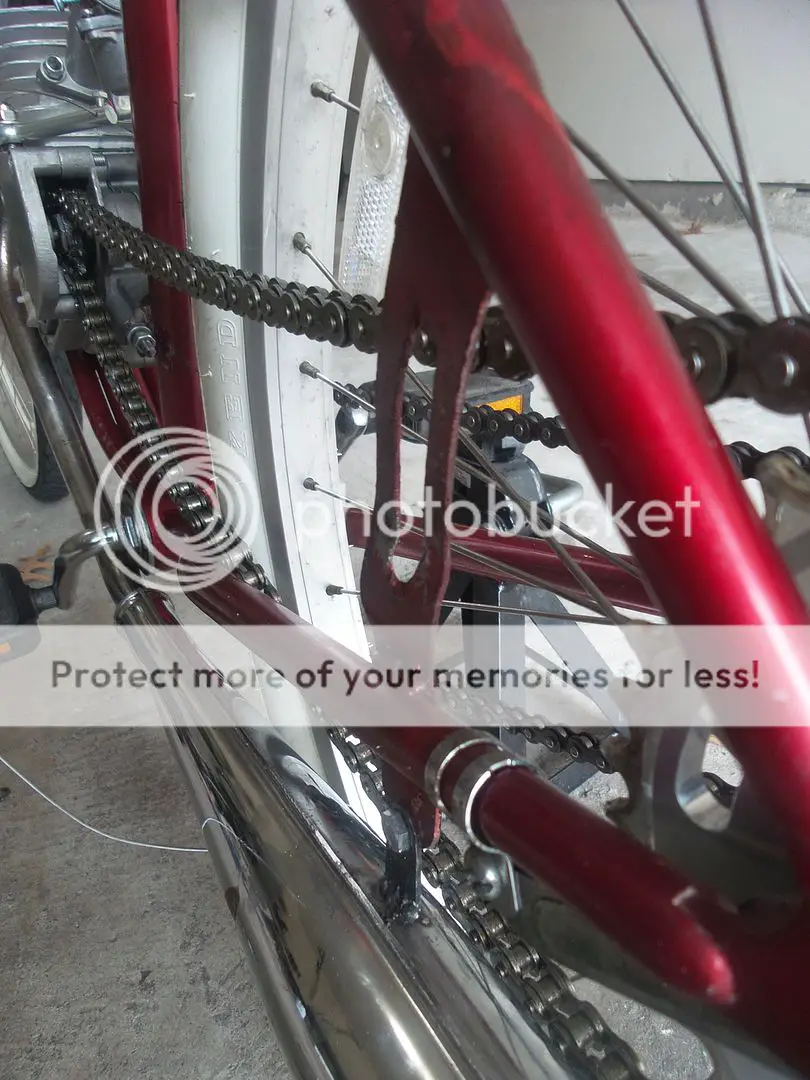

I added gusset from three of the horizontal tubes just infront of my engine mount to spread out the stresses. You did similar, but I did not have it up by the head tube.

One other area I did was add extra metal under the engine mount to the frame. This way I have not two point to hold the engine platform, but four evening out the stress there also.

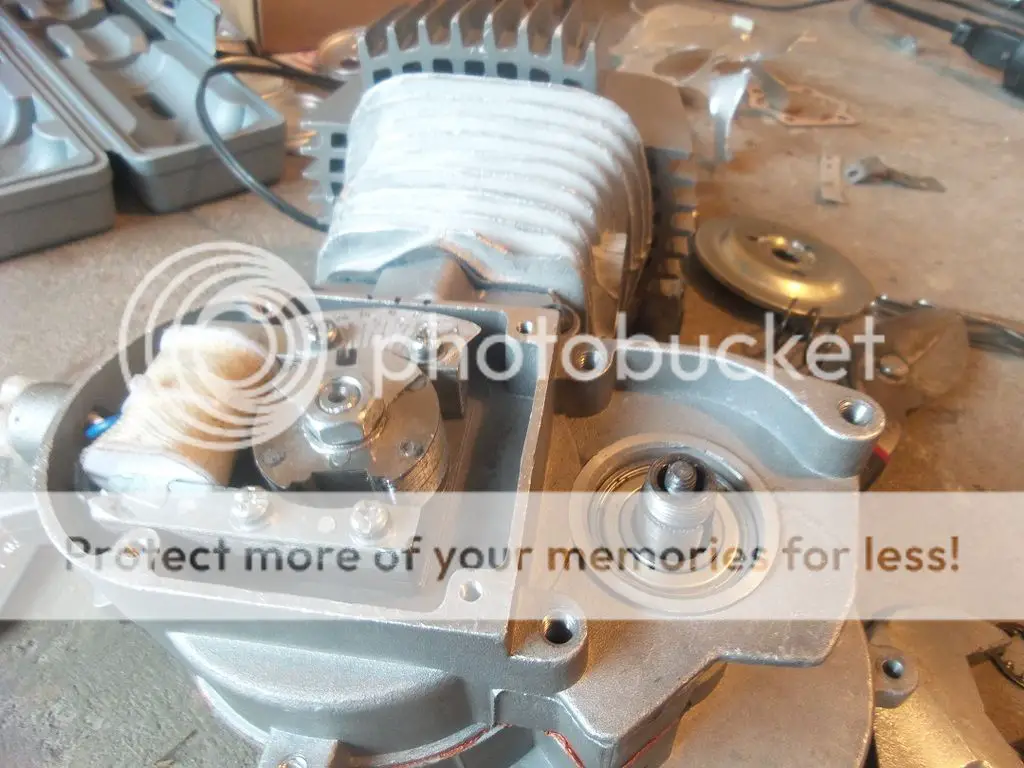

That two stroke engine should have good power, you would say!

MT

http://motorbicycling.com/showthread.php?t=54926 Trail Riding

Reason why I did mine at the Headtube was to reinforce the headtube since I really don't trust my welds yet.

Thanks for stopping by!

If you still have the coaster, I'd leave that in the rear. Front brake does most of the stopping anyways..just like a real motorcycle.

The coaster is washered for now so I can free spin the pedal backwards... But really reconsidering putting the coaster shoes back on.