You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trek Lime Lite 100cc build

- Thread starter Untame

- Start date

Untame

Member

Packed the muffler with one of these stainless steel scrubbies. Fluffed it up and poked it to the top of the can with a long screwdriver. I picked up two 2-packs, but one scrubby was more than enough. I also cut the exhaust tube off the bottom of the cap because there was no room to push it back into the can.

Venice Motor Bikes

Custom Builder / Dealer/Los Angeles

Packed the muffler with one of these stainless steel scrubbies. Fluffed it up and poked it to the top of the can with a long screwdriver. I picked up two 2-packs, but one scrubby was more than enough. I also cut the exhaust tube off the bottom of the cap because there was no room to push it back into the can.

View attachment 114612

That's not going to work!!!

The muffler won't be able to breathe through all that!

Untame

Member

We'll see. It is mostly air in there. Easy enough to change it up if it is too restrictive. Remember, I doubled the number of holes in the tube and added a couple holes to the bottom cap.That's not going to work!!!

The muffler won't be able to breathe through all that!

Untame

Member

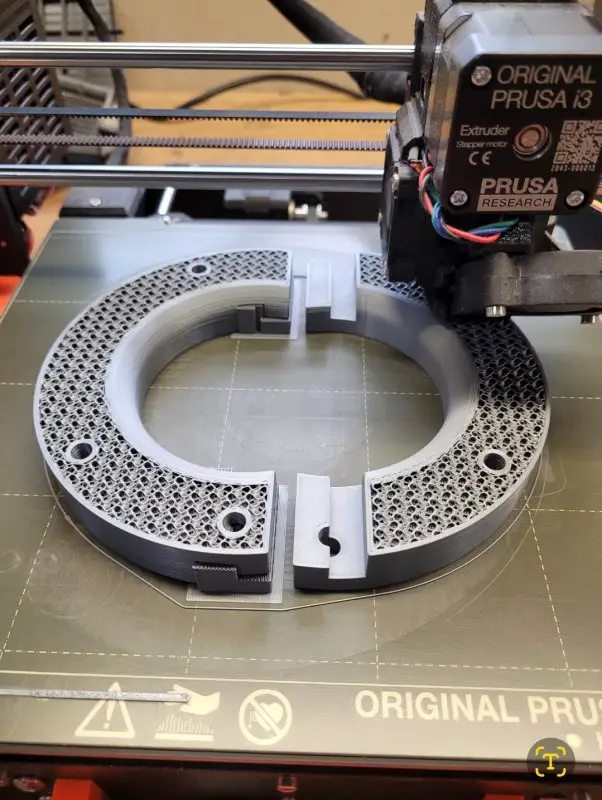

Retaining ring print is almost done (9 hours). Two halves which interlock. 20mm thick, but honeycomb interior with only 20% infill. 3mm wall thickness.

This part will not see any torque from the engine. It is strictly to keep the chainring adapter full engaged with the hub. Will be secured by 1/4in bolts with deformed thread lock nuts.

This part will not see any torque from the engine. It is strictly to keep the chainring adapter full engaged with the hub. Will be secured by 1/4in bolts with deformed thread lock nuts.

Venice Motor Bikes

Custom Builder / Dealer/Los Angeles

It looks interesting!!

What keeps the hub adapter locked into the hub to drive the wheel, (besides the five large bolts)?

What keeps the hub adapter locked into the hub to drive the wheel, (besides the five large bolts)?

Untame

Member

The seven small slots (3mm deep) index on the rear hub cover (tight fit). The inner retainer is just to ensure engagement between the chainring adapter and the hub cover. All of the torque is transmitted into the hub here - not to the sprockets.

Even though the hub cover is only 2.3mm thick it is fully supported on all sides by the chainring adapter. So the radial torque load is transmitted along the seven arc lengths (on a 82mm diameter). Looks weak, but I think the forces are all going the right direction as long as the chainring adapter maintains full engagement. Besides, engine torque will not be applied until there is rotary momentum.

Even though the hub cover is only 2.3mm thick it is fully supported on all sides by the chainring adapter. So the radial torque load is transmitted along the seven arc lengths (on a 82mm diameter). Looks weak, but I think the forces are all going the right direction as long as the chainring adapter maintains full engagement. Besides, engine torque will not be applied until there is rotary momentum.

Untame

Member

BTW... The 5 large bolts only hold the chainring to the adapter. There are five 1/4in bolts that go through the spokes (on a circle if seven - skip instance numbers 2 and 6) and through the two-piece retainer.It looks interesting!!

What keeps the hub adapter locked into the hub to drive the wheel, (besides the five large bolts)?

Venice Motor Bikes

Custom Builder / Dealer/Los Angeles

Keep an eye on the hub slots eventually cutting through the slot ends on the plastic adapter... The force of the 'on & off' throttle will probably cause them to eventually cut through the plastic, & then the engine force will be on the bolts going between the spokes; (with the sprocket constantly rocking back & forth damaging spokes).

If that does eventually happen; a good upgrade to your plastic hub adapter would be triangles that extend snugly between the spokes to actually drive the spokes (as well as the slots that you have now). There wouldn't be any problem with driving the wheel like that using the spokes.

If that does eventually happen; a good upgrade to your plastic hub adapter would be triangles that extend snugly between the spokes to actually drive the spokes (as well as the slots that you have now). There wouldn't be any problem with driving the wheel like that using the spokes.

Venice Motor Bikes

Custom Builder / Dealer/Los Angeles

That fix is very simple!Crank hits the exhaust. I think I will cut the exhaust pipe by the flange and rotate it so that the muffler discharges directly under the bike frame.

View attachment 114623

Use a Dremel tool (or small round file) & make the holes in the steel manifold into ovals.

Make the hole on the left of the picture go down a little, & the one on the right go up; & then you can simply turn the pipe inward to miss the pedal.

Doug Skullery

Member

That’s pretty trick and nice use of technology.Retaining ring print is almost done (9 hours). Two halves which interlock. 20mm thick, but honeycomb interior with only 20% infill. 3mm wall thickness.

This part will not see any torque from the engine. It is strictly to keep the chainring adapter full engaged with the hub. Will be secured by 1/4in bolts with deformed thread lock nuts.

View attachment 114618

Untame

Member

Finished. I took it out for a couple miles. Engine doesn't run smooth -- sounds like a hit and miss motor. Need to figure out if it is a fuel or spark issue. Spark plug is an E3-32. I replaced the boot with an MSD 90 degree non-resistor boot because the spring boot that came with the kit did not fit tightly on the plug. I am thinking fuel is the issue. I honed the mating surface on the cylinder where the carb attaches and made a new Felpro gasket. I am wondering about the janky clamp set up that attaches the carb -- maybe not sealing well?

Venice Motor Bikes

Custom Builder / Dealer/Los Angeles

Finished. I took it out for a couple miles. Engine doesn't run smooth -- sounds like a hit and miss motor. Need to figure out if it is a fuel or spark issue. Spark plug is an E3-32. I replaced the boot with an MSD 90 degree non-resistor boot because the spring boot that came with the kit did not fit tightly on the plug. I am thinking fuel is the issue. I honed the mating surface on the cylinder where the carb attaches and made a new Felpro gasket. I am wondering about the janky clamp set up that attaches the carb -- maybe not sealing well?

View attachment 114658

View attachment 114659

The bike's looking good!!

& good job on that sprocket adapter!

& good job on that sprocket adapter!As far as the poor performance... How are you mixing the gas & oil? (I would jump right in with 32:1)... Too much oil will cause poor performance

Another thing to consider; these engines need to get real hot before they start running good.

Also... they run better at higher RPMs; (so, trying to cruise it at low RPMs can cause that missing feeling that you're describing).

Untame

Member

I'm running 16:1 with Stihl synthetic oil (this ratio was recommended in the instructions for the first tank - after that, it specifies 20:1). It does run a little better once it warms up. I was hoping that after running it a bit I could open it up and get it to even out, but nope.The bike's looking good!!& good job on that sprocket adapter!

As far as the poor performance... How are you mixing the gas & oil? (I would jump right in with 32:1)... Too much oil will cause poor performance

Another thing to consider; these engines need to get real hot before they start running good.

Also... they run better at higher RPMs; (so, trying to cruise it at low RPMs can cause that missing feeling that you're describing).

Venice Motor Bikes

Custom Builder / Dealer/Los Angeles

I'm running 16:1 with Stihl synthetic oil (this ratio was recommended in the instructions for the first tank - after that, it specifies 20:1). It does run a little better once it warms up. I was hoping that after running it a bit I could open it up and get it to even out, but nope.

16:1 is way too much oil... like I said, jump up to 32:1 & ride it like you stole it!