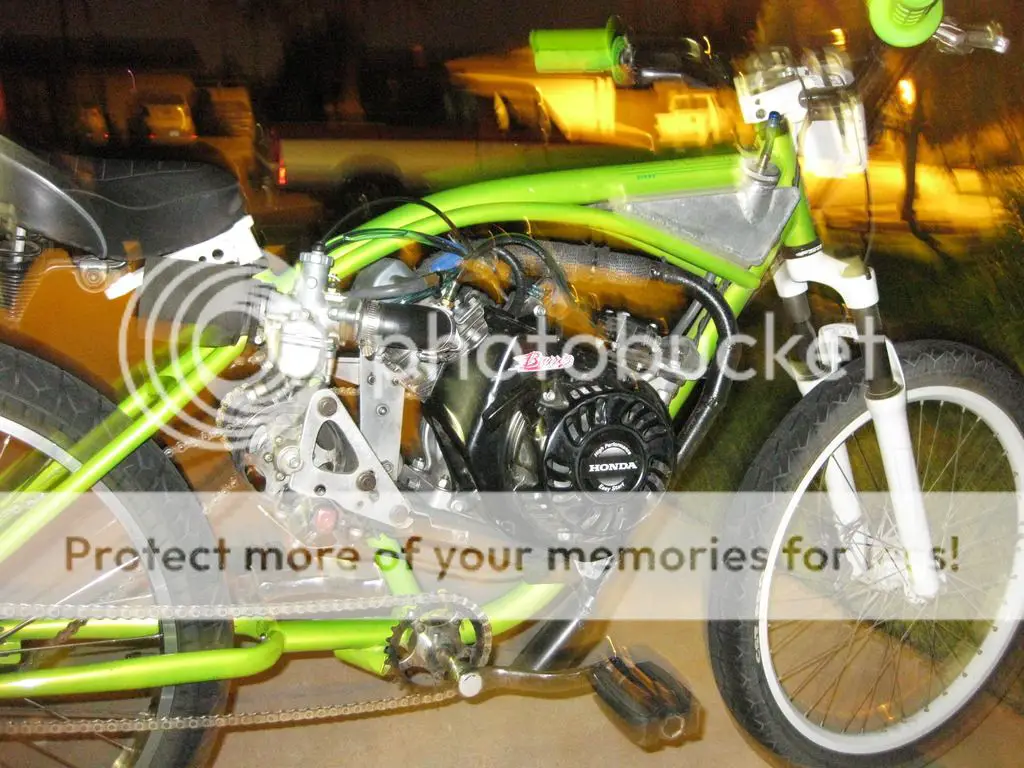

My build (from scratch-frame fabracation) so far has no tensioner. I dont wven think I need one for the motor drive chain. Im running the jackshaft billet plate type from Gasbike.net. I have that motor chain pulled tight. Side note: My pedal chain, which is a custom design has no slack so it worked out evenly. You guys know what Im saying?

Im talking about the issue of the two chains never tightning equally and requires at least one tensioner. Im guessing in my situation I can use a heavy fixed tensioner on the drive chain, but only as a guide, not a slack tensioner. Its the slack in the chain that promotes the stress on the tensioner (with jack shaft brake setup).

The less slack, the less stress on the tensioner, which gives a better function of the jackshaft brake as well. If your running disc brakes we all probably would be better off putting the slack on the pedal side with a tensioner there setup with a freewhee (no coaster brake)l.

Then use a tensioner on the drive chain side as well "only" to keep the chain from bouncing up and down and act as a guide, not for elimating slack. Kind of like a real motorcycle. Im aware some of you have this figured out already, Im just trying to put it out there again so maybe someone can benefit from saying it here in a restated way or add some ideas. everybodys build varies as we all know.