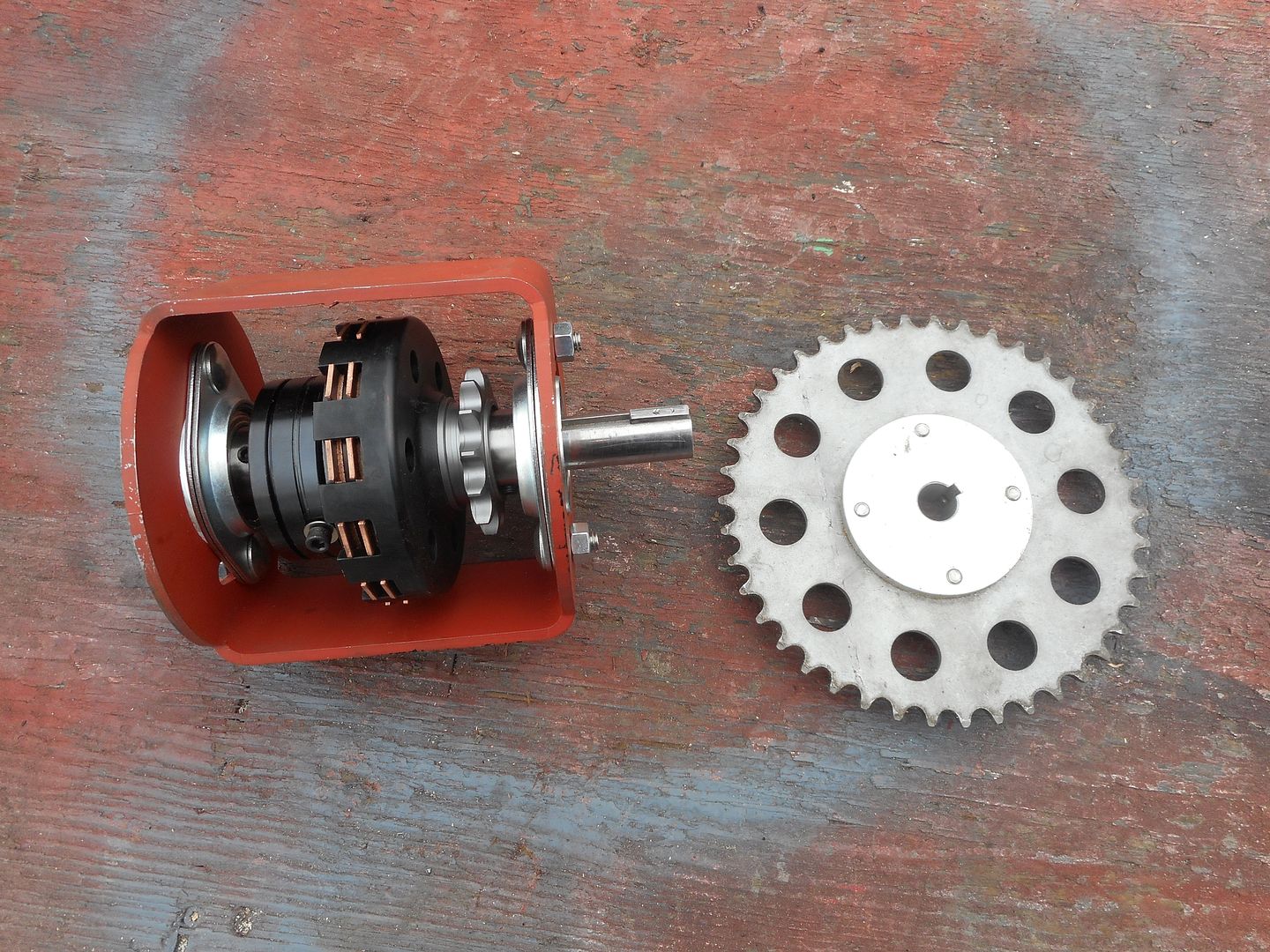

Just hooked back up with Dave, one of my old desert racing buddies and he wanted to put a Whizzer together. He's a great guy and we had tons of fun back in the day. I convinced him to build a Briggs bike first so he can have something to ride while gathering Whizzer parts. I gave him this Schwinn cruiser 20 or 30 years ago and we're going to use it. My pretty standard design with a tilted 5hp motor and front drum brake. He's a Harley biker and wanted apes, fish tail exhaust and a springer fork instead of moped stuff, so It will be a little different. Also a 3D Motorsports clutch converted to belt drive and mounted on the jack shaft.

Last edited: