ZipTie

Active Member

I've been away since last winter as I remember, do to being extremely busy with other projects. My last build here was the Copper Board tracker, built using a Schwinn Panther frame. I had another bare panther frame laying around so I thought I should get it started so I got a hold of a gas tank and rear wheel tool box for powder coating. I brought every down to the coaters and picked out a light moss colored willow green.

I was going to do a Indian tribute build using brown and cream for accents. I went to pick it up and it was all coated a bright yellow... Oh crap they made a little mistake.

if you know anything about powder coating they cant put green over the yellow or it would just bleed through. so they offered to somehow remove all the coating using high heat and start over... I felt bad at that point and just said it was OK mistakes happen, Ill just take the parts as they are as removing the coating with high heat might damage the frame anyways. They then offered me a generous 75.00 discount and I was on my way even though I really wanted the willow green bike.

So i was off to a bad start but decided on a new accent color scheme, look and went with the flow.

The bike is almost done except for the chain and graphics but I will post this thread as if I am doing it real time.

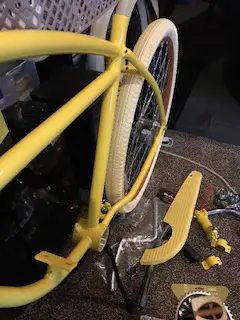

perhaps it will inspire some aspect of somebodies build in the future or component handling as I did a few unique things to it. This is maybe my last and final build. The color is a light yellow with a tad a brightness

like a early 80s corvette yellow.

My 13 year old daughter AJ wants to help her Dad every step of the way in attaching and fabricating every part and I think its awesome that she will be learning a ton about tools, drilling, cutting, grease, motors, ball bearings, graphics, style and mechanics, and the satisfaction that comes with building something from almost scratch.Something many kids never experience nowadays. At only 13, she has a keen eye and is a good artist and is a joy to be around.

Here is the color and some of the components and a painting she expertly painted as our plan of what it will look like.

I was going to do a Indian tribute build using brown and cream for accents. I went to pick it up and it was all coated a bright yellow... Oh crap they made a little mistake.

if you know anything about powder coating they cant put green over the yellow or it would just bleed through. so they offered to somehow remove all the coating using high heat and start over... I felt bad at that point and just said it was OK mistakes happen, Ill just take the parts as they are as removing the coating with high heat might damage the frame anyways. They then offered me a generous 75.00 discount and I was on my way even though I really wanted the willow green bike.

So i was off to a bad start but decided on a new accent color scheme, look and went with the flow.

The bike is almost done except for the chain and graphics but I will post this thread as if I am doing it real time.

perhaps it will inspire some aspect of somebodies build in the future or component handling as I did a few unique things to it. This is maybe my last and final build. The color is a light yellow with a tad a brightness

like a early 80s corvette yellow.

My 13 year old daughter AJ wants to help her Dad every step of the way in attaching and fabricating every part and I think its awesome that she will be learning a ton about tools, drilling, cutting, grease, motors, ball bearings, graphics, style and mechanics, and the satisfaction that comes with building something from almost scratch.Something many kids never experience nowadays. At only 13, she has a keen eye and is a good artist and is a joy to be around.

Here is the color and some of the components and a painting she expertly painted as our plan of what it will look like.