I think the concept is at the point were it is being over engineered. My original hope was to come up with bolt on (rear sprocket included) I know there are currently some good things out there for gearing of the rear heel, but given that we can easily pancake a couple of different size sprockets to the left side, a simple tensioner/derailer would be nice. Three speed hubs, and jack shafts kinda get away from the original concept. I also subscribe to the idea of simple means less to go wrong which leads to higher reliability.

Currently here are the problems I see that need solving: First the chain tension, switching between sprockets leaves lots of chain to slack out. Secondly the derailer, the drive chain needs to stay above the chain stay to give the drive sprocket enough teeth to drive the chain, so copying the right side tensioner is not an option.

A few sound concepts to consider: Shifting under power may not be advisable, but because the left sprockets do not freewheel we can use the rotation of the wheel to drive the chain through the shift, similar to how the front derailer works on a regular bike. Tensioner and derailer can be two seperate units, again look at the front derailer, all it does is move the chain, rear derailer maintains tension. The two unit design would allow for a "poor man" shift kit be cause with just a decent tensioner, one could stop the bike and manual move the chain to the desired sprocket.

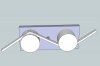

Just what I have so far from my tinkering, I currently have multiple sprockets, my current problem to tackle is the tensioner...