I'm just trying to be nice and imform you of the

obvious, see these nuts have caps. You couldn't over-tighten them unless you were a gorilla on meth.

Buying a $60 tool you don't need-priceless.

Thank you for the photo. I have seen a lot of these on bicycles. I'm sorry if my english is not the best. I just started learning it 2 years ago and I'm doing the best I can. My (Babylon software) dictionaries and Google apparently don't know what is a cap (mechanically speaking) either, so I rely on members to answer these little things. Thank you again.

EDIT: my mistake, I found that my dictionaries and Google know what it is if I type "cap nut". That appears to be the official name of this little metal part.

One of the very first pieces of advice I read was to get rid of the cap screws and buy real hi-grade nuts. I bought the sick bike parts head stud kit, two sets to be exact. One in 6mm and one in M8 1.00 for 66 cc motors.

Yes, this is a very valid recommendation. I know an awsome shop which is totally dedicated to bolts, screws and related. I'm definitely going there to buy high grade ones.

$60? I said nothing about an S&K torque wrench. I bought my 1/4" beam type 25 years ago at a used tool shop for $7. They don't have to be exact, just have to read the same every time.

Even here, in Brazil, a place where you pay lots of times more for a product than in other countries, I found nice torque wrenches for R$ 24,00 (U$ 15,00), which I think is considerably cheap.

For a proper head gasket seal you don't just torque to the specified torque from the start, you go up in stages. I start the M8 nuts at 2.5 ft lbs and go up 2.5 lbs at a time until I reach 12.5 lbs. You also don't go in a circle around the head tightening the nuts. I use a "Z" pattern or you can also use a "X" pattern. Failure to do this can cause the gasket to leak. You will know it's leaking when black oily crud is coming out from under the head. Ignoring this will cause what is called "torching". The hot exhaust gasses will burn a groove or tunnel out of the cylinder, ruining the head or jug. The head can be saved by doing the glass & sandpaper routine. Torched cylinders are toast, you then need a new one.

After a motor has been run a bit you need to check the torques on the head. Do this when the motor is cold. Hot torques can vary wildly when rechecked cold.

Aw man, thank you so much for coming to my topic.

All the infos are being organized in little topics in a Word document I'm creating.

You see, you're really helping me to develop this

You really have to accept that these motors are a crap shoot.

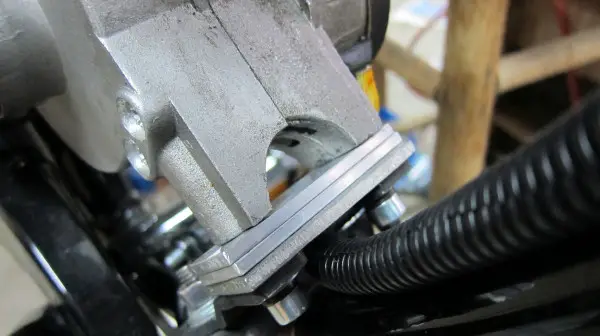

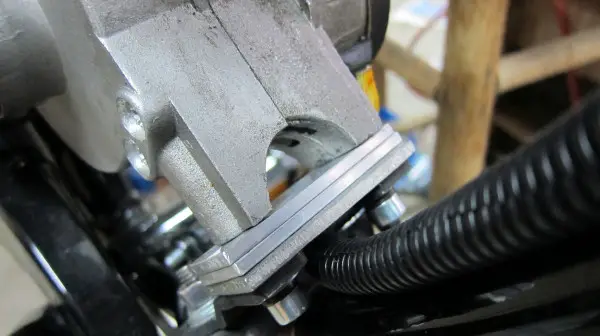

Here is my front mount.

Now my motor works fine, something that actually amazes me, but this why I will never buy another. There is no way that this should have ever left the factory. I am using spacers to mount, so the eigth inch out of round is not really a factor.

But this is just not acceptable. Many here have had motors that did not run new out of the box. Some here have motors with thousands of miles.

Are you feeling lucky?

Okay. I'm starting to realize the low quality of these engines now. Then, what would you recommend? Taking advantage of the chinese kit parts and using them with Honda stationary engines? That could be a good idea for durability and low maintenance, couldn't it?