You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tube frame Ebike build

- Thread starter Tony01

- Start date

Oldbiscuit

Well-Known Member

Tony, just curious as to why a mono shock ? Why not go with one on each side of the swing arm. It would give you more range of motion, wouldn’t it ?

Tony01

Well-Known Member

Leverage and availability. Lots to choose from. It’s 4.5” from the pivot while the axle is 20” from the pivot. So 1” of shock travel equates to 4.44” at the axle. This one has a range of 2.6” now limited to 1.8” or so.Tony, just curious as to why a mono shock ? Why not go with one on each side of the swing arm. It would give you more range of motion, wouldn’t it ?

Dual shocks would need to be long travel, lower spring rate, if they are mounted closer to the axle than the pivot. Each spring would need to be 1/2 the max load.

A short monoshock spring and two long dual shock springs have the same total max load. But further from pivot is higher travel lower spring rate because max load = travel*rate

Tony01

Well-Known Member

The little bikes we build are rarely a good fit as I’m a big guy, but I prefer them over full size motorcycles. I try to build within my riding limits. I live in that grey area between motorized bike and motorcycle, even though my bikes for the last few years would tend to be considered slow motorcycles.Looks good, if it's a good fit for you that's all that matters. I built one bike that looked good but didn't have the right feel for me, now I go by what I like and what's comfortable.

Greg58

Well-Known Member

I'm at the age that I'm satisfied cruising at 25-26 mph, I ve built and still have a bike with a big bore iron sleeve engine that is very fast, I just don't like the ride of the larger 2-stroke engines. I have rode the little 48cc powered bikes as much as 70 miles in a day, the engine on my main cruiser is balanced very good, that makes it fun to ride.

Tony01

Well-Known Member

If you top out let’s say 35mph with what’s considered bicycle performance you could probably get 50 miles per kWh. To get kWh multiply your nominal batt voltage by capacity in Ah. I get about 10–12 miles per kWh and even less if climbing a mountain; that’s light motorcycle performance.What kind of distance can you get with the typical electric powered bike? I ride mostly in rural farm areas and generally do at least 30 miles on a ride.

Tony01

Well-Known Member

Been working on the odds and ends now. Decided my swingarm could use some triangulation cause those twin 1x.065” tubes didn’t seem too strong.

Repaired my kickstand to have that snappy lock at each end. Just had to move the bolt for the spring further from the pivot.

When I get to the point of having a to-do list the end is in sight...

Paint isn’t on there yet. I decided I would go with the custom motorcycle registration process for this one. So I’m not sure if they will give me a plate for a vin or if I have to pound those numbers in myself. Another item on the to-do list is a rear brake for the brake inspection. For that I’ll fab up a foot lever and run it to a mechanic rear disc caliper.

I must have two 12v harnesses, one for hazard lights which work whether the bike is turned on or not, and one for running. Taking a trip to dmv with my application for title and statement of construction today or tomorrow.

I tried to find a company that will insure a custom vc406 motorized bike. There is an old thread on here that pretty much says you don’t need insurance. If an accident occurred I’m sure the law would be disseminated to where I’d be at fault. The only way to do it is to go thru the special Construction process and get a vin from the DMV which can then be looked up and written for. Well my bike isn’t really freeway ready but I could if I want to now. Good to know!

Repaired my kickstand to have that snappy lock at each end. Just had to move the bolt for the spring further from the pivot.

When I get to the point of having a to-do list the end is in sight...

Paint isn’t on there yet. I decided I would go with the custom motorcycle registration process for this one. So I’m not sure if they will give me a plate for a vin or if I have to pound those numbers in myself. Another item on the to-do list is a rear brake for the brake inspection. For that I’ll fab up a foot lever and run it to a mechanic rear disc caliper.

I must have two 12v harnesses, one for hazard lights which work whether the bike is turned on or not, and one for running. Taking a trip to dmv with my application for title and statement of construction today or tomorrow.

I tried to find a company that will insure a custom vc406 motorized bike. There is an old thread on here that pretty much says you don’t need insurance. If an accident occurred I’m sure the law would be disseminated to where I’d be at fault. The only way to do it is to go thru the special Construction process and get a vin from the DMV which can then be looked up and written for. Well my bike isn’t really freeway ready but I could if I want to now. Good to know!

Last edited:

Tony01

Well-Known Member

Done a lot lately. The odds and ends are taking time.

Anyway a lot of stuff got added to the to-do list and I knocked a bunch of those things off in the past week. Some of them just need to get welded in.

Going to register this one as a motorcycle so I need a working rear brake. Got this caliper off Amazon for $8... found an old mongoose suspension frame rear end for the brake tabs and an old 160mm rotor..

Fabbed up my upper frame triangulation tubes. Big job in itself. Tacked em in today.

Fabbed up footpegs with swivelling mounts.

Found this shift lever off some old 1969 engine. Welded up the clamp, drilled out to half inch, fabbed up some mounts and a little arm that will weld to it to pull the rear disc cable and brake light switch off the same old bike. Welded in my kickstand mount as well seen in the far corner.

Also fabbed up my front seat mount and J-plug mounts, only crossbar shown.

Hope to finish the metalwork in the next 2-3 days.

Anyway a lot of stuff got added to the to-do list and I knocked a bunch of those things off in the past week. Some of them just need to get welded in.

Going to register this one as a motorcycle so I need a working rear brake. Got this caliper off Amazon for $8... found an old mongoose suspension frame rear end for the brake tabs and an old 160mm rotor..

Fabbed up my upper frame triangulation tubes. Big job in itself. Tacked em in today.

Fabbed up footpegs with swivelling mounts.

Found this shift lever off some old 1969 engine. Welded up the clamp, drilled out to half inch, fabbed up some mounts and a little arm that will weld to it to pull the rear disc cable and brake light switch off the same old bike. Welded in my kickstand mount as well seen in the far corner.

Also fabbed up my front seat mount and J-plug mounts, only crossbar shown.

Hope to finish the metalwork in the next 2-3 days.

Last edited:

Tony01

Well-Known Member

Been fabricating a lot past few days. Hurt my thumb right on the tip on Thursday with the grinder then hurt it again in the same spot today with the belt sander. Learning to break eggs with one hand the last few days guess I’ll get more practice.

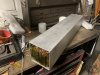

I screwed up my front seat mount, realized I was doing it wrong and it would be weak, so repurposed that piece as front controller mount and front batt box support which I welded in front of the frame today.

Wrapped up my battery in fish tape in preparation for fitting in the box. Did a test fit. Drops right in and fits flush on the end!

Only have one more item left on the metal fab to-do list which is rear seat support and rear lights/plate mount. Hope to do it in the morning and do all painting as today will be the warmest day this year so far. Also batt box, need to drill holes on my end cap and tap 10-32. Quick job.

Seat mount front- piece welded to underside of seat is C-channel with 5/16-18 nuts welded on inside. Frame front seat mount as you can see is a piece I got laser cut for some other job that I never used. That was a quick little job.

Here is how the controller will mount. Behind it will be a terminal block for battery and motor phase wire connections, and you can see the J1772 mount near the rear.

I screwed up my front seat mount, realized I was doing it wrong and it would be weak, so repurposed that piece as front controller mount and front batt box support which I welded in front of the frame today.

Wrapped up my battery in fish tape in preparation for fitting in the box. Did a test fit. Drops right in and fits flush on the end!

Only have one more item left on the metal fab to-do list which is rear seat support and rear lights/plate mount. Hope to do it in the morning and do all painting as today will be the warmest day this year so far. Also batt box, need to drill holes on my end cap and tap 10-32. Quick job.

Seat mount front- piece welded to underside of seat is C-channel with 5/16-18 nuts welded on inside. Frame front seat mount as you can see is a piece I got laser cut for some other job that I never used. That was a quick little job.

Here is how the controller will mount. Behind it will be a terminal block for battery and motor phase wire connections, and you can see the J1772 mount near the rear.

Attachments

Last edited:

Tony01

Well-Known Member

Got a lot done this weekend. This morning was the last of the frame fabrication and I had to decide where some components would go. I didn’t want to decide how the rear of the seat would be supported so I just welded in some tabs to bolt the supports to so I could get on with finishing the frame.

Ran out of the green paint. Can’t find it for sale anywhere unless I buy six cans for $100 including shipping. I’ll wait for it to come back in stock and give another coat in a few months or whenever.

All rust-oleum coats were 2x self etching primer, 3x filler primer, 2x metallic textured 251053 silver, and one light coat of racing green metallic 7252.

On to electrical.

Ran out of the green paint. Can’t find it for sale anywhere unless I buy six cans for $100 including shipping. I’ll wait for it to come back in stock and give another coat in a few months or whenever.

All rust-oleum coats were 2x self etching primer, 3x filler primer, 2x metallic textured 251053 silver, and one light coat of racing green metallic 7252.

On to electrical.

Tom from Rubicon

Well-Known Member

Triangulation = strong and rigid. Every post is a fab mind blower.

Tom

Tom

Tony01

Well-Known Member

Thank you Tom. I try. But this is the last time I do something as unique as this. Each tube on each side of this frame is unique. 11 per side. Mirror image of the other side. So 22 unique tubes for two sides. I’ll do another tube frame but will design for more like tubes to reduce fabrication and hand fitting time.Triangulation = strong and rigid. Every post is a fab mind blower.

Tom

Sidewinder Jerry

Well-Known Member

I got a long kickstand on my bike because it's top-heavy. The bottom of the kickstand is an old jammed-up ratchet wrench.Been working on the odds and ends now. Decided my swingarm could use some triangulation cause those twin 1x.065” tubes didn’t seem too strong.

View attachment 112840

Repaired my kickstand to have that snappy lock at each end. Just had to move the bolt for the spring further from the pivot.

View attachment 112841

When I get to the point of having a to-do list the end is in sight...

View attachment 112842

Paint isn’t on there yet. I decided I would go with the custom motorcycle registration process for this one. So I’m not sure if they will give me a plate for a vin or if I have to pound those numbers in myself. Another item on the to-do list is a rear brake for the brake inspection. For that I’ll fab up a foot lever and run it to a mechanic rear disc caliper.

I must have two 12v harnesses, one for hazard lights which work whether the bike is turned on or not, and one for running. Taking a trip to dmv with my application for title and statement of construction today or tomorrow.

I tried to find a company that will insure a custom vc406 motorized bike. There is an old thread on here that pretty much says you don’t need insurance. If an accident occurred I’m sure the law would be disseminated to where I’d be at fault. The only way to do it is to go thru the special Construction process and get a vin from the DMV which can then be looked up and written for. Well my bike isn’t really freeway ready but I could if I want to now. Good to know!

How heavy is it all going to be ?? I'm impressed with the engineering looks like it's good to 150hp+.. Shame it's an electric build...Triangulation = strong and rigid. Every post is a fab mind blower.

Tom

Attachments

Sidewinder Jerry

Well-Known Member

That looks like my Jalapeno popper holder for the grill lolDone a lot lately. The odds and ends are taking time.

Anyway a lot of stuff got added to the to-do list and I knocked a bunch of those things off in the past week. Some of them just need to get welded in.

Going to register this one as a motorcycle so I need a working rear brake. Got this caliper off Amazon for $8... found an old mongoose suspension frame rear end for the brake tabs and an old 160mm rotor..

View attachment 112922

View attachment 112923

Fabbed up my upper frame triangulation tubes. Big job in itself. Tacked em in today.

View attachment 112924

Fabbed up footpegs with swivelling mounts.

View attachment 112925

Found this shift lever off some old 1969 engine. Welded up the clamp, drilled out to half inch, fabbed up some mounts and a little arm that will weld to it to pull the rear disc cable and brake light switch off the same old bike. Welded in my kickstand mount as well seen in the far corner.

View attachment 112926

Also fabbed up my front seat mount and J-plug mounts, only crossbar shown.

View attachment 112927

Hope to finish the metalwork in the next 2-3 days.

Those electrics fry it's all set up just needs a rotisserie... This one takes 2 D batteries so it can still keep an even brown before during and after the smoke show...That looks like my Jalapeno popper holder for the grill lol

Attachments

Tony01

Well-Known Member

It’s going to be about 180-190lbs. Electric or gas the principles of propulsion are exactly the same. Instead of using heat in a cylinder to turn a crankshaft, the motor runs electricity through a coil to make it an electromagnet that acts on a magnet that passes by it... my motor is essentially an electromagnetic 32 cylinder radial engine.How heavy is it all going to be ?? I'm impressed with the engineering looks like it's good to 150hp+.. Shame it's an electric build...

I like electrics cause they attract far less attention from dudes... and cops.