You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi from the UK - INDIAN Board Tracker tribute, my first build

- Thread starter PeteMcP

- Start date

PeteMcP

Well-Known Member

Will there be a torque stay using one or more of the case bolts to take the load, rather than just rely on the engine mounting bolts?

Hi Ludwig,

Update on the torque stay point you raised.

Today I fitted DECOLINER's drive chain connecting the gearbox's output sprocket to the rear wheel sprocket. All straightforward and so far so good.... but when I pressed just one finger lightly to the chain to test for correct tension, even this was sufficient pressure to deform (read skew) the motor's anti-vibration rubber pads noticeably, particularly the left two pads nearest the 'box. So much so in fact that the gearbox moved far enough rearwards to foul the left side pedal when rotating. There was 4mm pedal clearance between the gearbox and pedal prior to installing the chain, so if slight finger pressure alone was enough to cause the chain - when stationary - to haul back on the gearbox and deform the rubber mounts, it goes without saying there'll be a whole lot more force and movement when I fire the motor up and the chain starts flailing round.

Sooo...I need to get my thinking cap on here. I figure for sure those 15mm tall anti-vibration rubber mounts the motor is sitting on must be swapped out for something solid - maybe urethane or just plain alloy. I can't simply discard them and use nothing, ie, mount the motor direct to it's metal mount, because that would lower the motor/gearbox by 15mm, resulting in the bottom of the gearbox fouling the left side pedal.

Looks like fitting a torque stay may also turn out to be an absolute necessity - and that's before I even think about firing up the motor...

PeteMcP

Well-Known Member

Last edited:

PeteMcP

Well-Known Member

CHAIN GUARDS / FENDER BUMPER FABRICATED...

Now that both DECOLINER's drive chains have been fitted, I turned my attention to fabricating the left/right chain guards. In an effort to maintain the bike's deco theme, I designed the guards hoping to create an impression of 'speed whiskers' flowing rearwards from the polished alloy motor mount to the tip of the rear fender, where they'll double-up as the rear fender mount/bumper protecting a yet to be fitted tail-light. The guards were built using 3/8" aluminium rod and will eventually be mirror polished to match the motor mount. Pics - hurriedly shot at close of play this evening - show the guards loosely in place. Tomorrow will be a polishing day....

Now that both DECOLINER's drive chains have been fitted, I turned my attention to fabricating the left/right chain guards. In an effort to maintain the bike's deco theme, I designed the guards hoping to create an impression of 'speed whiskers' flowing rearwards from the polished alloy motor mount to the tip of the rear fender, where they'll double-up as the rear fender mount/bumper protecting a yet to be fitted tail-light. The guards were built using 3/8" aluminium rod and will eventually be mirror polished to match the motor mount. Pics - hurriedly shot at close of play this evening - show the guards loosely in place. Tomorrow will be a polishing day....

PeteMcP

Well-Known Member

All joints are pinned with lengths of M6 studding. I'm almost done polishing the alloy rods which make up the chain guards. All being well, I'll post a pic or two tomorrow showing the components and how they fit together.How did you fasten the tubs together back by the rear wheel?.....thanks .......Curt

PeteMcP

Well-Known Member

PeteMcP

Well-Known Member

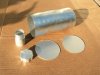

NEW SOLID ALLOY ENGINE MOUNTS FITTED...

Installing the motor on anti-vibration rubber mounts - see second pic - turned out to be a non-starter. Problem is, these mounts feature two separate bolts rather than one single bolt, so have way too much 'give' for my particular application, causing the motor to move backwards and resulting in loss of chain tension (refer back to my comments in post no. 63 of this thread). So I had no choice but to rethink my plans and swap-out the rubber bushes for new solid alloy mounts. These have solved the issue. Motor is now absolutely rigid on its frame mount. To make sure, I took DECOLINER out for a debut ride today and had no chain tension problems pedaling the length of the village main street and back. What's most noticeable, compared to my INDIAN tribute bike, is DECOLINER's virtually total lack of 'engine drag' thanks to its centrifugal clutch.

Installing the motor on anti-vibration rubber mounts - see second pic - turned out to be a non-starter. Problem is, these mounts feature two separate bolts rather than one single bolt, so have way too much 'give' for my particular application, causing the motor to move backwards and resulting in loss of chain tension (refer back to my comments in post no. 63 of this thread). So I had no choice but to rethink my plans and swap-out the rubber bushes for new solid alloy mounts. These have solved the issue. Motor is now absolutely rigid on its frame mount. To make sure, I took DECOLINER out for a debut ride today and had no chain tension problems pedaling the length of the village main street and back. What's most noticeable, compared to my INDIAN tribute bike, is DECOLINER's virtually total lack of 'engine drag' thanks to its centrifugal clutch.

PeteMcP

Well-Known Member

FUEL TANK PARTS ASSEMBLED...

I 'welded' up DECOLINER's fuel tank parts today. This was the first time I've attempted to weld aluminium and I'm extremely pleased with how things turned out. I used a combination of Durafix and Alubuild 300 rods to assemble the tank, which have a melting point of approx. 730 and 300 degrees respectively. I used nothing more than a butane gas torch as a heat source. I followed the simple and basic instructions supplied with these rods which I purchased from UK eBay sellers. I also watched a couple of Youtube vids to familiarize myself with the procedure prior to jumping right in.

Have to say there was nothing complicated about the process. Neither rods required the use of flux but the Durafix requires the objects being joined to be vigorously cleaned using the stainless steel wire brush provided with the kit of 4 x rods I purchased.

I assembled the tank by first attaching the disc-shaped ends to the cylindrical tank body using the Durafix rods. Followed by fixing the filler neck in place using the Alubuild 300 rods. I couldn't be happier how sharp the tank looks after a little clean-up using files and abrasive paper. Pics show the outcome.

Now I know some folks out there will object to this process being termed 'welding' and I suppose they're right - this process is more akin to brazing, or even soldering in the case of the Alubuild 300 rods which are flux cored. But at the end of the day DECOLINER's tank was assembled easily, neatly, and I never came anywhere close to melting anything. Think you need a pulsed MIG or maybe even a TIG set-up to 'weld' aluminium parts together? Think again...

Fancy building your own gas tank - or anything else made of aluminium? Go for it using these economical products. If I can do it, anyone can.

I 'welded' up DECOLINER's fuel tank parts today. This was the first time I've attempted to weld aluminium and I'm extremely pleased with how things turned out. I used a combination of Durafix and Alubuild 300 rods to assemble the tank, which have a melting point of approx. 730 and 300 degrees respectively. I used nothing more than a butane gas torch as a heat source. I followed the simple and basic instructions supplied with these rods which I purchased from UK eBay sellers. I also watched a couple of Youtube vids to familiarize myself with the procedure prior to jumping right in.

Have to say there was nothing complicated about the process. Neither rods required the use of flux but the Durafix requires the objects being joined to be vigorously cleaned using the stainless steel wire brush provided with the kit of 4 x rods I purchased.

I assembled the tank by first attaching the disc-shaped ends to the cylindrical tank body using the Durafix rods. Followed by fixing the filler neck in place using the Alubuild 300 rods. I couldn't be happier how sharp the tank looks after a little clean-up using files and abrasive paper. Pics show the outcome.

Now I know some folks out there will object to this process being termed 'welding' and I suppose they're right - this process is more akin to brazing, or even soldering in the case of the Alubuild 300 rods which are flux cored. But at the end of the day DECOLINER's tank was assembled easily, neatly, and I never came anywhere close to melting anything. Think you need a pulsed MIG or maybe even a TIG set-up to 'weld' aluminium parts together? Think again...

Fancy building your own gas tank - or anything else made of aluminium? Go for it using these economical products. If I can do it, anyone can.

PeteMcP

Well-Known Member

A FEW MORE SMALL JOBS CROSSED-OFF THE LIST....

Work on DECOLINER's fuel tank has stalled while awaiting delivery of a 1/8" NPT hose tail for the fuel pipe. So I took the opportunity to crack on with a few more small jobs today.

Fitted the diecast alloy tail light. Installed a Sturmey Archer front brake lever (with handbrake function) and hooked up the front brake cable. Exhaust brackets finally showed-up so the pipe is now mounted properly instead of being suspended by string from the Brooks saddle as in previous pics. Detailed the motor/mount with some deco-themed alloy trim pieces matching those on the TRM tank sides. Shaped and polished some alloy trim for the front fender. Swapped-out the black handlebar grips that came with the restricted throttle I ordered (thanks for the tip Ludwig, I'll start off with the throttle adjusted to 'partially restricted' till I become familiar with the mini-moto engine's capabilities). The new brown grips better compliment the tyres and saddle... and the brown leather tool bag I've ordered in which the fuel tank will be suspended behind the saddle.

Work on DECOLINER's fuel tank has stalled while awaiting delivery of a 1/8" NPT hose tail for the fuel pipe. So I took the opportunity to crack on with a few more small jobs today.

Fitted the diecast alloy tail light. Installed a Sturmey Archer front brake lever (with handbrake function) and hooked up the front brake cable. Exhaust brackets finally showed-up so the pipe is now mounted properly instead of being suspended by string from the Brooks saddle as in previous pics. Detailed the motor/mount with some deco-themed alloy trim pieces matching those on the TRM tank sides. Shaped and polished some alloy trim for the front fender. Swapped-out the black handlebar grips that came with the restricted throttle I ordered (thanks for the tip Ludwig, I'll start off with the throttle adjusted to 'partially restricted' till I become familiar with the mini-moto engine's capabilities). The new brown grips better compliment the tyres and saddle... and the brown leather tool bag I've ordered in which the fuel tank will be suspended behind the saddle.

PeteMcP

Well-Known Member

Man that's KOOL! Center strip on the fender, how did you make that? Is it just flat stock, i like it. Such a clean build.......Curt

Curt,

I used half-round aluminium stock for the tank and fender trim. I simply cut the trim strips to length, filed/sanded their rounded ends, shaped them using my rolling bars, then hand polished them to a mirror finish. Pic shows the tank top alloy trim strip being shaped using rolling bars in my workshop. Hope this helps.

Incidentally, today I decided to spray DECOLINER's front fender trim the same Nocciola Bronze colour as the tank/frame. I felt I needed a contrast between the trim and chrome fender - otherwise the trim just looked as if it was part of a stamped crested fender. Just my opinion...

Gave the twins an airing on this fine Autumn day...

Last edited: