MysterySandwich

New Member

So I've been working on this thing since last summer, pouring around $800 into this thing, being a highschooler... that's a lot.

I've always had problems with this thing, having to replace part after part, and never had it working for more than a 2 weeks, something eventually goes wrong. I admit most of those things are my fault, but it's really frustrating to have to push this heavy bike a couple miles up hill whenever it breaks down.

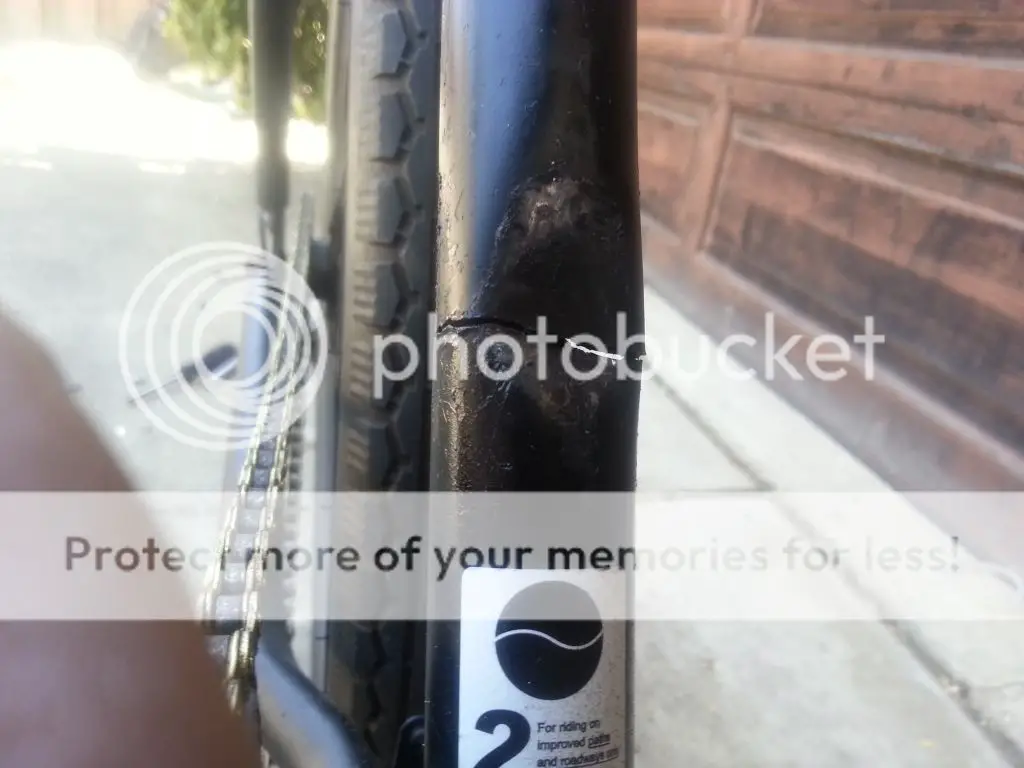

This weekend I saw one of my front mount studs broken off, I can't easy-out the thing, it won't work. Then I saw my down tube has a big crack.

I think I'm done -- how much should I be able to sell this on craigslist? This really greasy engine, and cracked Nirve B1? I guess this is more of a rant... hope all goes well for everybody else.

I've always had problems with this thing, having to replace part after part, and never had it working for more than a 2 weeks, something eventually goes wrong. I admit most of those things are my fault, but it's really frustrating to have to push this heavy bike a couple miles up hill whenever it breaks down.

This weekend I saw one of my front mount studs broken off, I can't easy-out the thing, it won't work. Then I saw my down tube has a big crack.

I think I'm done -- how much should I be able to sell this on craigslist? This really greasy engine, and cracked Nirve B1? I guess this is more of a rant... hope all goes well for everybody else.