jasonh

New Member

Really it depends on exactly how are little black box functions. My guess is that it charges on the + and discharges when it gets a -. If this is the case then simply putting the coil 180 degrees out, and also rotating the magnet 180 degrees out would probably work.

What I would do is before changing anything, take a timing light to the motor and get yourself a reference mark on the small sprocket on the clutch side. (mark a white dot on the sprocket, start motor, trigger timing light, make a mark on the motor case where the timing is) This way you'll know if your timing is out of sync or not, and if any small adjustments need to be made.

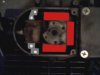

I had also been thinking of something like you're suggesting, but I was considering removing some material from the motor case so I could position some beefy coils on the top and bottom of the rotor.

What I would do is before changing anything, take a timing light to the motor and get yourself a reference mark on the small sprocket on the clutch side. (mark a white dot on the sprocket, start motor, trigger timing light, make a mark on the motor case where the timing is) This way you'll know if your timing is out of sync or not, and if any small adjustments need to be made.

I had also been thinking of something like you're suggesting, but I was considering removing some material from the motor case so I could position some beefy coils on the top and bottom of the rotor.