Agreen

Member

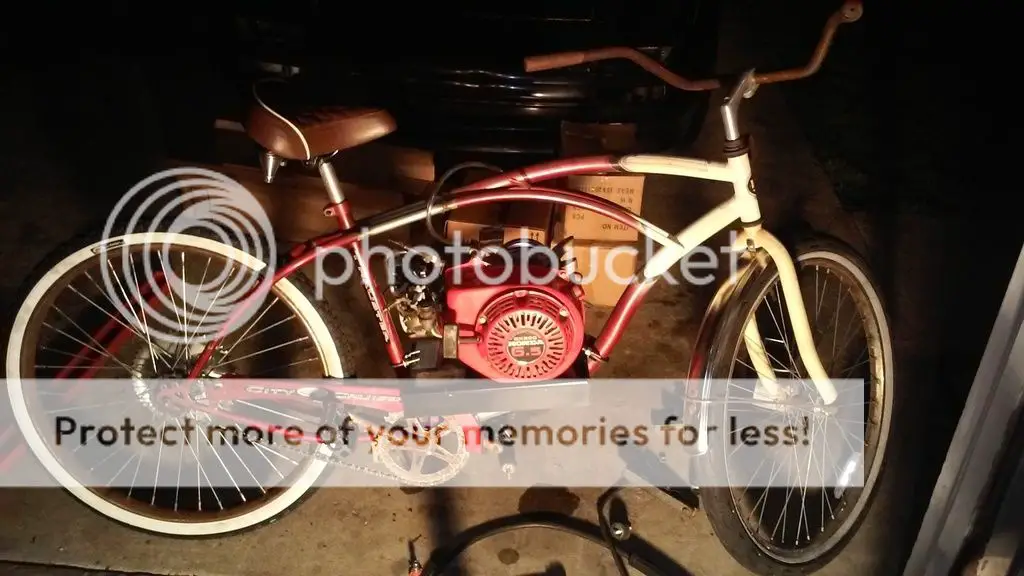

Slow progress. That's the only way to describe it now. Between my Rx7 project, multiple house projects, and rusty, everything is going slow.

So I finally got my pillow blocks in. I mocked them up, but I need to space them down a little, so I need to make another trip to the hardware store.

A friend was over the other day helping me with my car and we got talking about the bike. I fired it up for him, but forgot that I had only started the governor removal process. I had only gotten as far as taking the linkage and lever off. That meant the actuating rod inside had free reign to go wherever it wanted. And it did. It turned into a pretzel inside the engine. Luckily it didn't damage anything, so I was able to finish the removal tonight. Everything came out great, and it runs a heck of a lot better without it, for sure!

Hopefully the jackshaft goes smoothly and I'll be able to ride it soon. Slowly. I haven't finished lacing in the disc hub. I need some 250mm spokes still. I have 260mm spokes and they poke out through the rim. There seem to be a lot of choices out there. I just want some simple 12ga 250mm spokes. Too much to ask?

-Terrence

So I finally got my pillow blocks in. I mocked them up, but I need to space them down a little, so I need to make another trip to the hardware store.

A friend was over the other day helping me with my car and we got talking about the bike. I fired it up for him, but forgot that I had only started the governor removal process. I had only gotten as far as taking the linkage and lever off. That meant the actuating rod inside had free reign to go wherever it wanted. And it did. It turned into a pretzel inside the engine. Luckily it didn't damage anything, so I was able to finish the removal tonight. Everything came out great, and it runs a heck of a lot better without it, for sure!

Hopefully the jackshaft goes smoothly and I'll be able to ride it soon. Slowly. I haven't finished lacing in the disc hub. I need some 250mm spokes still. I have 260mm spokes and they poke out through the rim. There seem to be a lot of choices out there. I just want some simple 12ga 250mm spokes. Too much to ask?

-Terrence