I bought I bought an engine kit a while back and finally got around to installing it. I bought it off the Wish app so I really don't know what manufacturer or model ionly that it's 80cc. I used a kit from bikeberry for the motor mounts and it had thick rubber bushings and long studs. I had to use that because the motor would not fit in my frame otherwise. Then the chain was rubbing the frame, so I use the tensioner sort of as a guide and turned it inward slightly just enough that the chain actually had clearance. I took the bike out and it was a lot of fun I don't think it did more than about 15 miles an hour. 2 things I noticed is it was very rattly and at full speed the motor would actually wag left and right just a little bit is that normal? Also when I had it at Full Throttle the bike would alternate running smooth and bogging down. After riding for a little while I went to go pull out of a side street and the motor spun around shearing off both bolts in the front of the motor. I've seen posts about cutting a groove in the bolts but they an 1/16 to an 1/8th in the bolt hole, I'm afraid to weeken the block or have a cracked start because of it. So I'm going to take it to the machine shop to get them removed. Is it worth trying to tap bigger bolts in there?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New guy with a few problems

- Thread starter APRules2

- Start date

allen standley

Well-Known Member

If we could look at a pic of your forward mount as is now your questions could be answered. To be succinct - The engine should be secure to frame solid. NO RUBBER between motor and frame. Otherwise ^ that will happen.

I will try to take a picture of my engine as soon as the rain lets up. Its interesting that you say that because Bike berry actually says this mount will prevent broken studs,got to love when you get poor quality and lies straight from the company. Could it have just failed because they were hardware grade studs instead of grade 5 or 8? Heres a link https://www.bikeberry.com/bbr-tunin...MIm4KM_sj64gIVkYzICh3H5AmDEAQYASABEgKEp_D_BwE

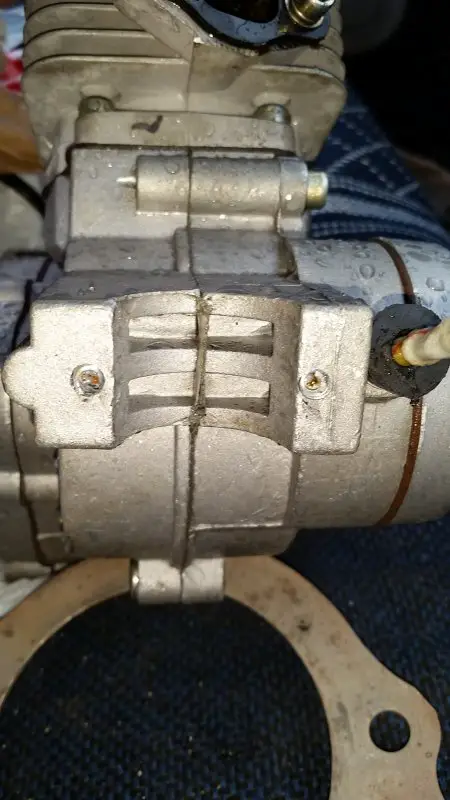

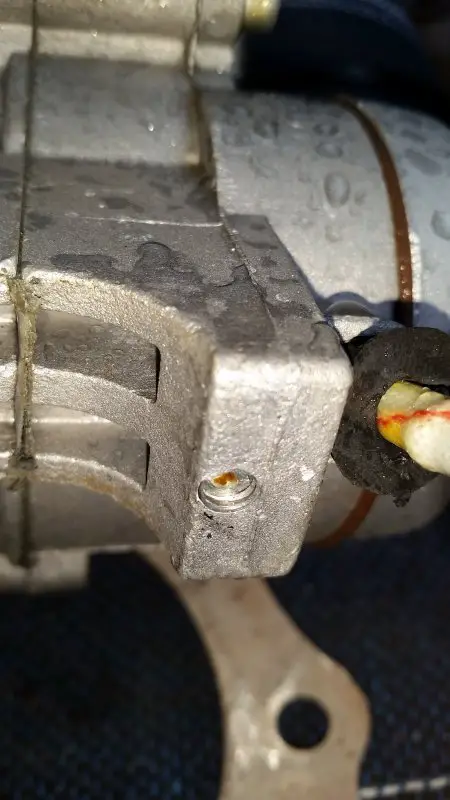

OK I ran out and took a couple pics, I could grind a slot in the left side no problem, but the right side looks like it broke 2-3 threads in. Maybe I'm wrong but if this thing is capable of breaking it's self, isn't cutting a slot into the motor mount area going to help start a crack?

From what I've read all these motors are made different, does mine have enough meat in it to safely drill out to a larger size stud like Ive heard mentioned on other posts. 1/4 seems do able but what about 5/16? Or am I Just over thinking things and getting a better grade 6mm stud will be enough to prevent an encore performance...

allen standley

Well-Known Member

Dremmel tool job. yeah you gotta go deep with one, but that's all you can do to save it. Goal is to cut a slot in the center of the broken studs. use a narrow screwdriver to unscrew it. Hopefully it wasn't wound in and bottomed out too tight. If you could replace them with threaded rod from hardware / auto supply store (metric) you will be ok. Be sure to do a good job removing metal dust and grinding before trying to remove. A little penetrating oil may help, Clean well and use blue locktite when re-assmbling.

does mine have enough meat in it to safely drill out to a larger size stud?

NO. Let's not go there yet.

does mine have enough meat in it to safely drill out to a larger size stud?

NO. Let's not go there yet.

Last edited:

allen standley

Well-Known Member

curious what frame you are using. Beach cruiser type or Diamond frame multi speed?

MEASURE TWICE

Well-Known Member

Screw Extractors like EasyOuts are used, but to drill exact center of an uneven surface of the broken bolt part way down the threaded hole takes a sharp bit and maybe a drill press. Would not attempt by hand drill. The one that broke with some left sticking out the threads maybe some one has tried before, use a needle nose pliers and grab it and try to unscrew the broken bolt. I think maybe a professional might use a drill press and first use a grinding tool to make a smoother surface to get a sharp bit to not wobble after center punching. Then the EasyOut is used to get it removed. There does not look to be enough clearance for drilling out larger to tap or use HeliCoil Thread Repair.

I once heard of some one using some way of arc tack welding something to the broken part and the unscrewing the broken bolt, but have not heard if this is just a wacky idea or not.

https://www.instructables.com/id/Removing-a-Broken-Bolt-or-Stud-With-TIG/

I once heard of some one using some way of arc tack welding something to the broken part and the unscrewing the broken bolt, but have not heard if this is just a wacky idea or not.

https://www.instructables.com/id/Removing-a-Broken-Bolt-or-Stud-With-TIG/

MEASURE TWICE! The video shows the bolt broke off on out side, the one he has is below the surface, smarter is to try and weld a nut to it.

A tip to get the drill straight is to drill a bolt the same size as the one on engine insert as far as you can the drill, the bolt will automatically center it..............Curt

A tip to get the drill straight is to drill a bolt the same size as the one on engine insert as far as you can the drill, the bolt will automatically center it..............Curt

Greg58

Well-Known Member

I have used left hand twist drill bits to remove broken bolts from the bottom of forklift cylinders, they were always below surface. The bottom of the mast is one inch thick, I would center punch it and drill about 1/4” deep then slow down as slow as I could till the bit stuck and backed out the broken bolt.