Specs:

Coil 1) 300 turns of 26GA., (inner coil), connected to the White wire 6V.

Coil 2) 3,600 turns of 35 GA., (outer coil), connected to the blue wire.

The black wire is connected to the coil frame.

Jim

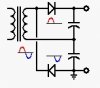

An easier way to double the voltage is to use a voltage doubler as shown in the attached circuit diagram (found elsewhere on the Internet).

This circuit is a half-wave rectifier with two capacitors which produce an output voltage that is twice the transformer secondary voltage, but the available current is only half the current that would be available from a half-wave rectifier by itself. This circuit placed between the magneto (white wire) and a 12v, 3-Watt incandescent bulb should work. The cost of the circuit and time involved in building it are insignificant. You can get the parts at Radio Shack. The output of the circuit will not be “clean” enough to charge batteries, and may not be clean enough to drive LEDs. But, you could probably clean it up enough for LEDs will a large filter capacitor across the output. Charging batteries would require voltage regulation as well.

For academic discussion purposes, if I had time to experiment with rewinding the white wire coil of a magneto to get 12v from it, I would assume the following as a place to start:

1) I need twice the length of the original wire, 2) but the new wire would be half the area of the original wire, 3) I would only expect to get half the current from the new coil, but 4) I would still get 3 watts of power from the new coil.

Based on the above, if the existing coil is 300’ of 26GA wire, which is 0.0159” in diameter and has an area of 0.000199in^2, then the new coil would be 600’ of 29GA wire, which has an area of about half of 0.000199in^2 and a diameter of about 0.0113”.

The diameter of the 29GA wire is 70% of the diameter of the 26GA wire, so I would expect the new coil to be larger in diameter than the original coil. This could be a problem, and may require rewinding the spark coil as well with smaller gage wire with the hope that enough of the wire could be put on in the space available so that the CDI work (anyone know if the CDIs are really that sensitive to voltage?).

I would probably build a coil-winding jig to facilitate nice flat and neat winds on the coil. The jig could be chucked into an electric drill operating at a slow enough speed that I could guide the wire by hand. This would be the only way to minimize the diameter of the coil.

The "academic discussion" above is speculation on my part ‘cause I haven’t had time to research it, and it’s based on what I remember from a power distribution class I took in engineering school a zillion years ago.