liveforphysics

New Member

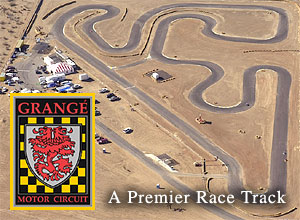

I'm building a new bike for this Willow springs race June 18th.

I ordered $660usd in CroMo tubing in various sizes last night.

My friend Paul ordered some various bending/jigging/clamping tools for frame building and a new welding table.

The motor came today, hand delivered by its creator, who is a VERY awesomely smart guy. Thank you Diederik!

The frame will be rigid rear, possibly sprung front, if and only if I can find a fork with an extremely stiff dampening rate, extremely rigid bodies and crown, and just a couple inches of suspension at the most. IMHO, 99.9% of suspension forks on bikes racing a kart track are going to be a big hinderer to riding rather than a help.

Brake will be dirtbike based this time rather than the Hayse stroker ace downhill brakes on 8.5" rotors that I used last time, which faded something awful at the death race, and regularly boil and warp rotors on the pink bike. Brakes are extremely important road racing, having something you know wont fade gives you the confidence to commit to corner entry speeds you wouldn't otherwise try. I would like to get the Brembo setup off a KTM if possible. Might just take the brake setup off one of my KTM's and borrow it for this bike.

So, step one to any build is sourcing and deciding on the pieces that will best work together, and step 2 is making all the custom parts and systems to attach them together and make them play well. I'm exiting phase 1 at this point, and excited to get going on phase 2 this weekend.

So, now I've got to find a decent controller for my motor... So, let's measure the resistance and see what ball-park we're in for controller loading.

So, you will notice on that sexy sexy 6.5digit ethernet linked Kethley DMM and the Sorensen 8-125 power supply current set to 50amps, we have a phase winding resistance of ~50mOhm. The motor has a KV of 28. This basically means it won't be straining any controller, but it will need some voltage to get it up to speed, so let's see what we have for controllers in the 120v area.

Hmm... Hmm... so many to choose from! What to pick! What to pick! Since I'm not going to be running more than 10hp (as agreed with the fellow hosting this event), I think I will go with the baby size#2 sevcon, which will be just about right for my modest power needs here.

Now we need a ~120v battery... something pretty light and stiff, with plenty of capacity.

Ahh, yes, here we go, didn't even have to get out of my chair to reach a compact little pack that will suit my needs.

So, now it's time for a little CADoodling to design a sprocket adapter for this fantastic motor that was built to mount a prop, and time to begin picking suitable frame geometry.

Here are some pics of the hall placement. This is absolutely perfect placement.

However... then we were spinning the rotor and experimenting with pushing the halls closer and further from the rotor to try to get the dutycycle as close to 50% as possible, and pushed it into the rotor and tore a couple of the sensors off... D'oh! Now I gotta re-do it.

I ordered $660usd in CroMo tubing in various sizes last night.

My friend Paul ordered some various bending/jigging/clamping tools for frame building and a new welding table.

The motor came today, hand delivered by its creator, who is a VERY awesomely smart guy. Thank you Diederik!

The frame will be rigid rear, possibly sprung front, if and only if I can find a fork with an extremely stiff dampening rate, extremely rigid bodies and crown, and just a couple inches of suspension at the most. IMHO, 99.9% of suspension forks on bikes racing a kart track are going to be a big hinderer to riding rather than a help.

Brake will be dirtbike based this time rather than the Hayse stroker ace downhill brakes on 8.5" rotors that I used last time, which faded something awful at the death race, and regularly boil and warp rotors on the pink bike. Brakes are extremely important road racing, having something you know wont fade gives you the confidence to commit to corner entry speeds you wouldn't otherwise try. I would like to get the Brembo setup off a KTM if possible. Might just take the brake setup off one of my KTM's and borrow it for this bike.

So, step one to any build is sourcing and deciding on the pieces that will best work together, and step 2 is making all the custom parts and systems to attach them together and make them play well. I'm exiting phase 1 at this point, and excited to get going on phase 2 this weekend.

So, now I've got to find a decent controller for my motor... So, let's measure the resistance and see what ball-park we're in for controller loading.

So, you will notice on that sexy sexy 6.5digit ethernet linked Kethley DMM and the Sorensen 8-125 power supply current set to 50amps, we have a phase winding resistance of ~50mOhm. The motor has a KV of 28. This basically means it won't be straining any controller, but it will need some voltage to get it up to speed, so let's see what we have for controllers in the 120v area.

Hmm... Hmm... so many to choose from! What to pick! What to pick! Since I'm not going to be running more than 10hp (as agreed with the fellow hosting this event), I think I will go with the baby size#2 sevcon, which will be just about right for my modest power needs here.

Now we need a ~120v battery... something pretty light and stiff, with plenty of capacity.

Ahh, yes, here we go, didn't even have to get out of my chair to reach a compact little pack that will suit my needs.

So, now it's time for a little CADoodling to design a sprocket adapter for this fantastic motor that was built to mount a prop, and time to begin picking suitable frame geometry.

Here are some pics of the hall placement. This is absolutely perfect placement.

However... then we were spinning the rotor and experimenting with pushing the halls closer and further from the rotor to try to get the dutycycle as close to 50% as possible, and pushed it into the rotor and tore a couple of the sensors off... D'oh! Now I gotta re-do it.