You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clutch stuck? Rear tire won't spin forward

- Thread starter mpl535

- Start date

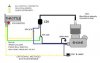

I enlarged your photo and I have to wonder about your ignition wiring. That long wire hanging down is obviously from the kill switch. When I look at it closely it appears that you have nothing attached to the black or white wire.

Check this diagram and make sure your wiring matches it.

Also, don't run the engine without the exhaust installed. That's not a good idea for several reasons.

Tom

Check this diagram and make sure your wiring matches it.

Also, don't run the engine without the exhaust installed. That's not a good idea for several reasons.

Tom

Attachments

Last edited:

tooljunkie

Member

op mentioned it had spark.it is a good idea to leave kill switch disconnected until its running,you can always stall it with the brake.or choke it.

i would tape up the white wire for sure.the grommet on the engine looks like its falling out,pull the cover and look closely at the wires, occasinally they break at the solder joint.

and add sealant to the grommet to keep it in place as well as keeping water out.

you were going in there to check the magnet anyway.

oh,and i think the choke is on(lever up)

it could be badly flooded.

i would tape up the white wire for sure.the grommet on the engine looks like its falling out,pull the cover and look closely at the wires, occasinally they break at the solder joint.

and add sealant to the grommet to keep it in place as well as keeping water out.

you were going in there to check the magnet anyway.

oh,and i think the choke is on(lever up)

it could be badly flooded.

Yeah, I saw that choke lever too but forgot to mention it. Down, choke is open, or off, up the choke plate is closed. In warm weather, and who isn't having warm weather right now, I don't use the choke. When it gets below 50 is the only time my engines need a little extra fuel to start quickly.

Try it with the choke open, lever down.

Tom

Try it with the choke open, lever down.

Tom

Has the OP even got the engine to turn over yet?

All this great advice to get it started and I haven't read that the crankshaft has gone a full 360* yet while trying to pedal start it.

Am I wrong? Did I miss a post?

Hey sorry I havent really clarified the status of my situation. I'm pretty sure my engine turns over when pedal starting it, my only worry is I loosened the flower nut a little bit to fix my original problem pedaling, so there is a possibility the clutch is slipping but I dont think so.

So now that the engine is (hopefully) turning over, I haven't been able to get it to start.

GearNut

Active Member

Ok, well that is a whole 'nother can o' beans.

I am going to start with the simple and cheap stuff first.

We can go much deeper if necesary.

There are only 4 things needed for a spark fired 2 stroke engine to run.

1. Air mixed with fuel at the correct ratio (carburetor).

2. Compression to squish the air and fuel for a good bang.

3. Ignition both strong and occurring at the correct point of crankshaft rotation to start the bang.

4. Get it turning over.

Air, there is plenty of it.

Fuel, old fuel is no good. There is not enough bang in it for the engine to run right.

Modern gasoline goes bad in 1 month, even sooner if it is an ethanol blend.

How old is the gas you used to mix with oil to make the fuel?

Assuming that the carburetor is ok...

Compression, you seem to have plenty of it!

Spark, The spark plug can tell us alot before we even check it for function.

After trying to start the engine for a while, remove the spark plug.

Is is wet? That would indicate that either the spark is not occurring at all or the carburetor is mixing too much fuel with the air.

It also could be a bad spark plug. A spark plug can spark a really nice, fat, blue-white spark when just resting on the cylinder head, but...

The conditions inside the combustion chamber are alot different than sitting on a cylinder head fin and a spark plug can fail under the strains of compression.

Speaking of that fat, blue-white spark, if it is instead a thin spark and yellowish in color, that is a weak spark. That will not have enough umph to operate the spark plug when under the strains of compression.

Check for loose electrical connections.

Is it dry? That would indicate that the carburetor is not mixing enough fuel with the air.

It could be a failure to get fuel to the carburetor from the fuel tank, a clogged fuel jet, or one that the factory forgot to install, or there is a very large intake leak. Using the choke should be able to overcome a small intake leak and at least get the engine started, but not running right. The choke sometimes can be of no help at all with a large enough intake leak.

I am going to start with the simple and cheap stuff first.

We can go much deeper if necesary.

There are only 4 things needed for a spark fired 2 stroke engine to run.

1. Air mixed with fuel at the correct ratio (carburetor).

2. Compression to squish the air and fuel for a good bang.

3. Ignition both strong and occurring at the correct point of crankshaft rotation to start the bang.

4. Get it turning over.

Air, there is plenty of it.

Fuel, old fuel is no good. There is not enough bang in it for the engine to run right.

Modern gasoline goes bad in 1 month, even sooner if it is an ethanol blend.

How old is the gas you used to mix with oil to make the fuel?

Assuming that the carburetor is ok...

Compression, you seem to have plenty of it!

Spark, The spark plug can tell us alot before we even check it for function.

After trying to start the engine for a while, remove the spark plug.

Is is wet? That would indicate that either the spark is not occurring at all or the carburetor is mixing too much fuel with the air.

It also could be a bad spark plug. A spark plug can spark a really nice, fat, blue-white spark when just resting on the cylinder head, but...

The conditions inside the combustion chamber are alot different than sitting on a cylinder head fin and a spark plug can fail under the strains of compression.

Speaking of that fat, blue-white spark, if it is instead a thin spark and yellowish in color, that is a weak spark. That will not have enough umph to operate the spark plug when under the strains of compression.

Check for loose electrical connections.

Is it dry? That would indicate that the carburetor is not mixing enough fuel with the air.

It could be a failure to get fuel to the carburetor from the fuel tank, a clogged fuel jet, or one that the factory forgot to install, or there is a very large intake leak. Using the choke should be able to overcome a small intake leak and at least get the engine started, but not running right. The choke sometimes can be of no help at all with a large enough intake leak.

Last edited:

Hey I just had a few basic questions.

When I try to check the magnet, the manual says the piston must be at top dead center. How do I move/keep the piston to that position? how would I know its in the right position if I can't see it?

And what do I do if the engine is flooded? Should I take apart the carb? Or does it drain out eventually?

The gas that I used was new from the pump as of a week or so ago. I mixed about 5-6 oz of two stroke oil into the gallon of fuel for a little less than a 20:1 ratio. And now that you mention it, when I took out the spark plug last time I was surprised to see that it was dry. Maybe I have a fuel or carb problem. I'll have to look into it.

How do I check if my spark plug is sparking?

Thanks for all the help guys, I really appreciate it. I'd be hopeless without it.

When I try to check the magnet, the manual says the piston must be at top dead center. How do I move/keep the piston to that position? how would I know its in the right position if I can't see it?

And what do I do if the engine is flooded? Should I take apart the carb? Or does it drain out eventually?

The gas that I used was new from the pump as of a week or so ago. I mixed about 5-6 oz of two stroke oil into the gallon of fuel for a little less than a 20:1 ratio. And now that you mention it, when I took out the spark plug last time I was surprised to see that it was dry. Maybe I have a fuel or carb problem. I'll have to look into it.

How do I check if my spark plug is sparking?

Thanks for all the help guys, I really appreciate it. I'd be hopeless without it.

Last edited:

tooljunkie

Member

funny you would say hopeless.

a friends father did not like me and another buddy.about 12 years ago.

he called me hopless,anybody can fix cars and my buddy was pathetic,he would never amount to anything.

i am now a certified auto technician,my buddy is a foreman for the local municipality.

guess the old guy was wrong,seeing as i have had to fix a car for him.

pull spark plug,re-attatch it to the wire and push bike around,the spark should be visible.

a little hard to see in direct sunlight.

to check the magnet,that same spark plug wrench should fit the nut,by turning it with spark plug out and a screwdriver touching the piston through spark plug hole,roll the magnet til its at its highest point.the slot on the shaft of the magnet should be at the 1:00 position.and the flats on the outside of magnet should be level.the install manual link posted above has a photo.

after thats checked,i guess its on to fuel delivery.

go check for spark first.

a friends father did not like me and another buddy.about 12 years ago.

he called me hopless,anybody can fix cars and my buddy was pathetic,he would never amount to anything.

i am now a certified auto technician,my buddy is a foreman for the local municipality.

guess the old guy was wrong,seeing as i have had to fix a car for him.

pull spark plug,re-attatch it to the wire and push bike around,the spark should be visible.

a little hard to see in direct sunlight.

to check the magnet,that same spark plug wrench should fit the nut,by turning it with spark plug out and a screwdriver touching the piston through spark plug hole,roll the magnet til its at its highest point.the slot on the shaft of the magnet should be at the 1:00 position.and the flats on the outside of magnet should be level.the install manual link posted above has a photo.

after thats checked,i guess its on to fuel delivery.

go check for spark first.

Last edited:

Finding TDC, Top Dead Center: This applys to our little Chinese 2 strokes, installed in the frame but the same method can be used for other engines. It's not dead on accurate as needed when timing a high performance race engine but it's close enough for our purposes.

I prefer using a wooden dowel as opposed to a metal tool such as a screwdriver. A wood pencil will suffice but you'll want it to be at least 6" long. This method can be used on the slant plug design heads but you might have to help support the pencil toward the verticle position. Straight plug head is a hands off operation.

Remove the spark plug, insert the pencil into the plug hole until it touches the top of the piston. Rotate the crankshaft slowly while watching the pencil. It might go down at first depending on where the piston is in its stroke but eventually as you continue to turn the crankshaft it will start to be pushed up and out of the plug hole. Finally, at TDC, top dead center of the piston stroke the pencil will begin to move downward again. Reverse the crankahaft rotation until the pencil comes back to its highest position. That is considered Top Dead Center. High performance engine builders rely on precision tools like a dial indicator and a degree wheel but we don't need to be that accurate.

When TDC is determined now is the time to check the magneto rotor (magnet) for proper location. The reason you want to check this is because in some cases the woodruff key that holds the rotor indexed to the crankahaft can be sheered allowing the rotor to be at the wrong position which will negatively impact ignition timing.

As was explained above, to check the ignition system, remove the plug and reconnect the high voltage lead (spark plug wire) then hold the plug firmly against the cylinder head cooling fins and spin the rear wheel, clutch engaged. Watch for a spark jumping the plug's electrodes. Keeping the plug firm against the head is essential for this test. The plug must be grounded to the engine to complete the electrical circuit.

Tom

I prefer using a wooden dowel as opposed to a metal tool such as a screwdriver. A wood pencil will suffice but you'll want it to be at least 6" long. This method can be used on the slant plug design heads but you might have to help support the pencil toward the verticle position. Straight plug head is a hands off operation.

Remove the spark plug, insert the pencil into the plug hole until it touches the top of the piston. Rotate the crankshaft slowly while watching the pencil. It might go down at first depending on where the piston is in its stroke but eventually as you continue to turn the crankshaft it will start to be pushed up and out of the plug hole. Finally, at TDC, top dead center of the piston stroke the pencil will begin to move downward again. Reverse the crankahaft rotation until the pencil comes back to its highest position. That is considered Top Dead Center. High performance engine builders rely on precision tools like a dial indicator and a degree wheel but we don't need to be that accurate.

When TDC is determined now is the time to check the magneto rotor (magnet) for proper location. The reason you want to check this is because in some cases the woodruff key that holds the rotor indexed to the crankahaft can be sheered allowing the rotor to be at the wrong position which will negatively impact ignition timing.

As was explained above, to check the ignition system, remove the plug and reconnect the high voltage lead (spark plug wire) then hold the plug firmly against the cylinder head cooling fins and spin the rear wheel, clutch engaged. Watch for a spark jumping the plug's electrodes. Keeping the plug firm against the head is essential for this test. The plug must be grounded to the engine to complete the electrical circuit.

Tom

Last edited:

So I checked the spark plug and I am getting a spark. Its kinda weak looking, then again I don't really know how its supposed to look, but its consistent.

Does this mean that my magnets fine and I shouldn't bother taking it apart? I also noticed that my spark plug was completely dry, am I not getting fuel into the engine? Maybe I should take a look at the carburator

Does this mean that my magnets fine and I shouldn't bother taking it apart? I also noticed that my spark plug was completely dry, am I not getting fuel into the engine? Maybe I should take a look at the carburator

Greg58

Well-Known Member

Loosen the screw on the bowl and check for fuel, the spring loaded plunger above it is vent to allow fuel to flow into the carb before the first start of the day. Its called the "tickler " for some reason, why I don't know. If you have starting fluid give it a small shot to see if it will hit.

Last edited:

Loosen the screw on the bowl and check for fuel, the spring loaded plunger above it is vent to allow fuel to flow into the carb before the first start of the day. Its called the "tickler " for some reason, why I don't know. If you have starting fluid give it a small shot to see if it will hit.

So I took apart my carburator and fuel is definitely getting from the tank into the carburator but not from the carb to the engine. I checked out the fuel jet and its not clogged, the intake and the choke seem to be working. I noticed that the carburator needle setup seemed a bit binded. I believe it was set up correctly but the throttle cable (silver) seems short causing the spring to be really tight between the metal cap and the barrel. Im not sure if the barrel is closing the valve properly because of it. Could this be my problem? How could I make the interior cable longer? Just cut off some of the black exterior casing?

Greg58

Well-Known Member

Here's a good one on the carb.

http://motorbicycling.com/showthread.php?t=195

http://motorbicycling.com/showthread.php?t=195

So I completely took apart and reassembled the carb and I think its working fine. All the ports and jets are clear and I fixed the spring/needle problem.

This might be a stupid question but what brings the fuel from the carb to the engine? Does the engine turning over create a vacuum, drawing the air/fuel mix into the engine? Because I think that might be the problem, no fuel or not enough is getting to the engine.

This might be a stupid question but what brings the fuel from the carb to the engine? Does the engine turning over create a vacuum, drawing the air/fuel mix into the engine? Because I think that might be the problem, no fuel or not enough is getting to the engine.