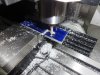

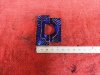

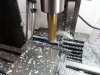

Next I'm going to weld the clamps to the slot bracket. I could have screwed everything together, but that would be even more time consuming. Besides we all know that anything that screws together on a MB comes unscrewed. I machined 1/4 in. slots in the ends of the bracket so it would be easy to square up the clamps on the bracket when welding. Whenever you butt weld two piece's together you should always chamfer the edges first. It makes for a much stronger weld. I had to lay down some weld near the clamp holes. This can be tricky at best and a disaster at worst. Hear is a little trade secret I'll share; put the solid end of a drill bit or the flat end of a transfer punch in the hole before welding. I used a steel transfer punch, if you are welding steel use a piece of brass in the hole. This will help transfer the heat off the wall of the hole and keep the weld puddle from flowing into the hole. This method is not fool proof, it takes practice.