You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Art Fish Mobile Motor Bike prior Motor Bike DIY'er build to add side car maybe?

- Thread starter MEASURE TWICE

- Start date

MEASURE TWICE

Well-Known Member

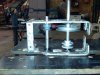

There are pictures of covers (not the art cover) coming together for the belt and large pulley near left side for protection of rider and other stuff from ground flying into fast moving parts.

Test Mig weld on thin sheet metal steel. I forgot that I could get some copper sheet metal underneath both steel thin pieces to help prevent punch through. Then I could have more heat and even get better flow on the pieces I attached to one another to make a one piece cover for both clutch and first pulley (large 10"). Actually talking about flow and no holes punch through, this was really not happening even with the voltage down at least setting.

To probably do Bondo over the ground down weld and smaller gaps where two parts no welded with extra pieces of sheet metal to fillet.

I might take some parts I use a low volt setting (actually improper extended distance the nozzle) and slow feed rate and globed till I got a mass enough over the metal parts to do some redoing over. I did come back initially after that thought and come in close proper distance and try to get to flow and no punch through. This is not like Tig where I could just use heat and no filler, but it worked to some extent.

If I were to take a copper sheet that is not suppose to stick to the steel underneath, I could try at a slow feed rate and try to reflow the weld.

Any thoughts on how to do this thin sheet metal appreciated! I will be doing some welding to frame tubing to attach nut or threaded coupler to make attachment points for skeleton frame to put fabric over to make fish art cover later.

The welding on the later would be of thicker than the sheet metal, so I will not have the issues as I have with this thin sheet metal.

MT

Test Mig weld on thin sheet metal steel. I forgot that I could get some copper sheet metal underneath both steel thin pieces to help prevent punch through. Then I could have more heat and even get better flow on the pieces I attached to one another to make a one piece cover for both clutch and first pulley (large 10"). Actually talking about flow and no holes punch through, this was really not happening even with the voltage down at least setting.

To probably do Bondo over the ground down weld and smaller gaps where two parts no welded with extra pieces of sheet metal to fillet.

I might take some parts I use a low volt setting (actually improper extended distance the nozzle) and slow feed rate and globed till I got a mass enough over the metal parts to do some redoing over. I did come back initially after that thought and come in close proper distance and try to get to flow and no punch through. This is not like Tig where I could just use heat and no filler, but it worked to some extent.

If I were to take a copper sheet that is not suppose to stick to the steel underneath, I could try at a slow feed rate and try to reflow the weld.

Any thoughts on how to do this thin sheet metal appreciated! I will be doing some welding to frame tubing to attach nut or threaded coupler to make attachment points for skeleton frame to put fabric over to make fish art cover later.

The welding on the later would be of thicker than the sheet metal, so I will not have the issues as I have with this thin sheet metal.

MT

Attachments

Last edited:

MEASURE TWICE

Well-Known Member

I felt that the inner cover for the large jack shaft pulley 10 incher needed to be able to be removed and installed independently of the jack shaft pillow bearing holders that fasten to the jack shaft pillow bearing holder brackets.

At the same time I was always concerned about the height of the double jack shaft and the tall brackets needing extra support so side to side strength is better. Forward to aft there is strength there simply because the bracket has length in the angle so it is inherent strong that way but not side to side.

It was not a problem with the shorter previous single jackshaft bracket as it did not allow leverage of it to be able to be pushed sideways. I know there really should not be sideways pressure there anyway, but I would like it more rigid so that the pillow bearing are snug and stay that way with just enough play to that without the belts in place they spin freely.

Fixed both in one shot welding the 7/32 bracket at the top with a seat post clamp to meet the two at the top. A longer bolt in the lower seat post clamp (actually not for the seat, just what I am using) will extend through the two brackets and fasten the top rear brackets. The rear to front brackets are already held together with the pillow bearing holders at the top so all is made more stable.

The need to have it easier to assemble all the jack shafts and pulleys was a lot easier when I did not have the inner cover in place. I thought I would be using the bolt that holds the pillow bearing holder on the left side for a dual purpose.

They would also hold on the inner cover by the fact that the bolts would go through all. It became apparent that having to take of the rear wheel and still have a bit of trouble reassembling, I decided to make the left pillow bearing holders upper and lower become one with the brackets by welding them in place. They are that way now.

The bolts are still in place as I used them as a jig to hold them when I welded, but they will be able to be removed and used to hold the inner cover after I grind and flap disk and clean some of this gel stuff half way through I tried with the MIG welding.

I also added a little extra height to the brackets to facilitate getting the clamp to the tubing to work out. It does not interfere with the exhaust manifold either.

There is a picture as a test weld on 7/32 metal with a lap weld and a hold on one flat to the underside flat. It puddle quite nice. I put it to test with hammer and a foot long crescent wrench to try to break weld or bend metal. Neither happened, but I could have destroyed my inch thick particle board bench.

MT

At the same time I was always concerned about the height of the double jack shaft and the tall brackets needing extra support so side to side strength is better. Forward to aft there is strength there simply because the bracket has length in the angle so it is inherent strong that way but not side to side.

It was not a problem with the shorter previous single jackshaft bracket as it did not allow leverage of it to be able to be pushed sideways. I know there really should not be sideways pressure there anyway, but I would like it more rigid so that the pillow bearing are snug and stay that way with just enough play to that without the belts in place they spin freely.

Fixed both in one shot welding the 7/32 bracket at the top with a seat post clamp to meet the two at the top. A longer bolt in the lower seat post clamp (actually not for the seat, just what I am using) will extend through the two brackets and fasten the top rear brackets. The rear to front brackets are already held together with the pillow bearing holders at the top so all is made more stable.

The need to have it easier to assemble all the jack shafts and pulleys was a lot easier when I did not have the inner cover in place. I thought I would be using the bolt that holds the pillow bearing holder on the left side for a dual purpose.

They would also hold on the inner cover by the fact that the bolts would go through all. It became apparent that having to take of the rear wheel and still have a bit of trouble reassembling, I decided to make the left pillow bearing holders upper and lower become one with the brackets by welding them in place. They are that way now.

The bolts are still in place as I used them as a jig to hold them when I welded, but they will be able to be removed and used to hold the inner cover after I grind and flap disk and clean some of this gel stuff half way through I tried with the MIG welding.

I also added a little extra height to the brackets to facilitate getting the clamp to the tubing to work out. It does not interfere with the exhaust manifold either.

There is a picture as a test weld on 7/32 metal with a lap weld and a hold on one flat to the underside flat. It puddle quite nice. I put it to test with hammer and a foot long crescent wrench to try to break weld or bend metal. Neither happened, but I could have destroyed my inch thick particle board bench.

MT

Attachments

Last edited:

MEASURE TWICE

Well-Known Member

Top dual jack shaft 4 brackets are now steady in place at the top by a clamp up high. Rock solid is the way it should be!

I have no way of doing a nice weld on the thin sheet metal, even with the backup plate of copper to prevent blow through. I get it welded and seems to be stronger than the metal, but looks like $^%!

One day I'll have a flame torch that is good enough to weld and braze.

I'll use epoxy resin or polyester resin with fiber glass cloth and cover over the metal rounded cover parts, but not before welding small angle brackets that can fasten the round front cover to the back plate. I can then paint it also after that.

The back plate is the one carved to the back edge of the engine. Later I cut it off round to match the cover where needed, but will come to that bridge when I cross it.

I found that popping on the v-belts across a short distance between pulleys on adjacent top and bottom jack shaft with the non-cast iron pulleys is not going to be OK. I ordered 2 cast iron pulleys to replace those ones.

Strange I thought that the 2 large aluminum 10 inch pulleys have not warped to popping on the belts (i.e. no idler pulleys), but it seems smaller pulleys have more stress at one point as they go on and had deformed just a slight bit. May have been OK, but rather not have trouble with them later.

The small cast iron pulley I will now have two of the same sized ones and will swap around to get a different ratio reduction of between half to a third the 44:1 ratio reduction, which will be the transformation from fish art parade vehicle to off road dirt bike.

MT

I have no way of doing a nice weld on the thin sheet metal, even with the backup plate of copper to prevent blow through. I get it welded and seems to be stronger than the metal, but looks like $^%!

One day I'll have a flame torch that is good enough to weld and braze.

I'll use epoxy resin or polyester resin with fiber glass cloth and cover over the metal rounded cover parts, but not before welding small angle brackets that can fasten the round front cover to the back plate. I can then paint it also after that.

The back plate is the one carved to the back edge of the engine. Later I cut it off round to match the cover where needed, but will come to that bridge when I cross it.

I found that popping on the v-belts across a short distance between pulleys on adjacent top and bottom jack shaft with the non-cast iron pulleys is not going to be OK. I ordered 2 cast iron pulleys to replace those ones.

Strange I thought that the 2 large aluminum 10 inch pulleys have not warped to popping on the belts (i.e. no idler pulleys), but it seems smaller pulleys have more stress at one point as they go on and had deformed just a slight bit. May have been OK, but rather not have trouble with them later.

The small cast iron pulley I will now have two of the same sized ones and will swap around to get a different ratio reduction of between half to a third the 44:1 ratio reduction, which will be the transformation from fish art parade vehicle to off road dirt bike.

MT

Attachments

Mr.B.

Well-Known Member

which will be the transformation from fish art parade vehicle to off road dirt bike.

MT

So are you giving up on the fish body?

I've really been looking forward to seeing that phase of your build.

-Kirk

MEASURE TWICE

Well-Known Member

It is dual purpose; the 44:1 ratio has to be a part of the fish build first. Soon to be testing that, but the cover must be done first so no mishap with the belt and large pulley so near my thigh and moving so fast.

I got the dual bracket jack shaft fastened at the top of the tube for stability, but found I needed to set adjustment of the clamp. I got that done and the jack shafts are in line now and have the bearings seated nice and spin freely without much play in them.

I used a t-square and also the wall straight edge post that at least I can see that the two jack shafts are parallel.

Now I can finish the covers that I have been working on also.

The skeleton frame that will either be from clamps to the frame or some flange nuts or coupler type nuts welded at specific spots on the frame is next.

Then some light weight metal or fiber glass rods that then should be connected at their extent with whatever I come up with. Just should be a little better than tinker toy wood press fits. The fabric flame proofed and sewn to attach like panels to the outer edge of the skeleton frame.

I've been looking for an alternate power source where gas is not allowed. This electric motor and at a first look I thought of this could be OK, but the belts they use are toothed. I’m to check back and see if there is a way they can sell me one that accepts a 5/8 bore v-belt type pulley.

http://www.monsterscooterparts.com/24-volt-200w-motor-belt-sprocket.html

If the shaft is smaller like a ¼ and is keyed for a v-belt it could work well too. They just don’t have it for that I’m suspecting and need to see what can be done with one of those toothed belt pulley type motors if I get one and need to convert it.

The gear type I suppose I could use, but my gearing down will become more difficult. The motor may have good torque and be OK with much less than 44:1, but at 6:1 I’m not sure it is OK.

Thanks Mr. B for your interest.

MT

I got the dual bracket jack shaft fastened at the top of the tube for stability, but found I needed to set adjustment of the clamp. I got that done and the jack shafts are in line now and have the bearings seated nice and spin freely without much play in them.

I used a t-square and also the wall straight edge post that at least I can see that the two jack shafts are parallel.

Now I can finish the covers that I have been working on also.

The skeleton frame that will either be from clamps to the frame or some flange nuts or coupler type nuts welded at specific spots on the frame is next.

Then some light weight metal or fiber glass rods that then should be connected at their extent with whatever I come up with. Just should be a little better than tinker toy wood press fits. The fabric flame proofed and sewn to attach like panels to the outer edge of the skeleton frame.

I've been looking for an alternate power source where gas is not allowed. This electric motor and at a first look I thought of this could be OK, but the belts they use are toothed. I’m to check back and see if there is a way they can sell me one that accepts a 5/8 bore v-belt type pulley.

http://www.monsterscooterparts.com/24-volt-200w-motor-belt-sprocket.html

If the shaft is smaller like a ¼ and is keyed for a v-belt it could work well too. They just don’t have it for that I’m suspecting and need to see what can be done with one of those toothed belt pulley type motors if I get one and need to convert it.

The gear type I suppose I could use, but my gearing down will become more difficult. The motor may have good torque and be OK with much less than 44:1, but at 6:1 I’m not sure it is OK.

Thanks Mr. B for your interest.

MT

Attachments

Last edited:

MEASURE TWICE

Well-Known Member

MEASURE TWICE

Well-Known Member

Transmission clutch with belt and pulley cover for the 10 inch first pulley for the 44:1 ratio lowering almost done. I can stand on it in one axis and it holds all my weight. Welds are looking crummy, but grinded and will probably put fiber glass with epoxy resin and paint over later.

A screen at the bottom and top by inside plate cover maybe for vent to let out heat that comes from adjacent to engine where it may adversely affect the belt.

Then I’ll finish to high temp copper forma-gasket for the corrugated exhaust pipe and fit the muffler. Now that the seat is lower I think the muffler cannot be under the banana seat. The art cover for parade when not off roading in the dirt will need a longer exhaust pipe to have the muffler outside the fabric cover, even though the fabric will be flame proof treated. I have a second pipe I will also need to make gaskets for.

The mounts on the frame for the skeleton to hold the fabric I will be using pre-threaded part from a pipe clamp. I’ll remove the zinc from the steel surface with acid or wire brush or sand wheel and weld to places on the frame so the skeleton can be assemble and removed making it modular.

MT

A screen at the bottom and top by inside plate cover maybe for vent to let out heat that comes from adjacent to engine where it may adversely affect the belt.

Then I’ll finish to high temp copper forma-gasket for the corrugated exhaust pipe and fit the muffler. Now that the seat is lower I think the muffler cannot be under the banana seat. The art cover for parade when not off roading in the dirt will need a longer exhaust pipe to have the muffler outside the fabric cover, even though the fabric will be flame proof treated. I have a second pipe I will also need to make gaskets for.

The mounts on the frame for the skeleton to hold the fabric I will be using pre-threaded part from a pipe clamp. I’ll remove the zinc from the steel surface with acid or wire brush or sand wheel and weld to places on the frame so the skeleton can be assemble and removed making it modular.

MT

Attachments

MEASURE TWICE

Well-Known Member

The opposite side cover started on, this to protect the delicate carb throttle linkages. Also maybe I will still try to make a snorkel to get the air filter intake up high on the frame next to the gas tank as was planned.

I had to use a different carb and that carb only likes using a paper air filter less restrictive than foam. It has not a round shape to the air filter housing intake, so remaking a way to route the snorkel from where the paper filter intake is about 5 each rectangular slots on two sides at right angles is a bit more complex.

MT

I had to use a different carb and that carb only likes using a paper air filter less restrictive than foam. It has not a round shape to the air filter housing intake, so remaking a way to route the snorkel from where the paper filter intake is about 5 each rectangular slots on two sides at right angles is a bit more complex.

MT

Attachments

MEASURE TWICE

Well-Known Member

Art Fish Mobile Motor Bike pic of inside cover on mb an landing

It came out of the sky just a little while from ......

In honor of another pilot-less landing on Mars for Sunday scheduled, I thought I'd keep you up to date.

The pics show the trimmed inside flat piece of cover for my dual jack shaft that the integral curved covers (for clutch and 1st 10 inch reduction pulley go for 4mph cruising option) that I'll fiber glass over to look better will be landing on.

The inside cover turned around and on edge in the woods has me thinking of some old Star Trek Series, the guy with the big head

Later when I get the curved outside cover fiber glassed more pics, then.

MT

It came out of the sky just a little while from ......

In honor of another pilot-less landing on Mars for Sunday scheduled, I thought I'd keep you up to date.

The pics show the trimmed inside flat piece of cover for my dual jack shaft that the integral curved covers (for clutch and 1st 10 inch reduction pulley go for 4mph cruising option) that I'll fiber glass over to look better will be landing on.

The inside cover turned around and on edge in the woods has me thinking of some old Star Trek Series, the guy with the big head

Later when I get the curved outside cover fiber glassed more pics, then.

MT

Attachments

Last edited:

MEASURE TWICE

Well-Known Member

Skeleton frame mounting bosses welded so can add/remove easyRe: Art Fish MB

The large 3/8 thread and coupler could be good enough for possible side car later if I think maybe I'll do that also. Is there such a thing as two side cars left and right sides? I suppose the 4 wheeler would be a kind of trike with another 4th wheel to propel between the two out rigger side car wheels?

Anyway not shown yet to glue to the couplers are these wood dowels covered with some kind of plastic laminate. I scavenged from the dumpster which is part of a collapsible drying rack, these dowels that have end parts that snap on and off. Then I would just leave the coupler or half the coupler as they are longer than needed in place with a short piece of threaded rod and lock washer and I could put the dowels on and remove easily.

Then I’m not yet sure how the ends of the dowels will connect. Maybe like Tinker Toy, or something else and they will be at right angle to the outward facing dowels making a fish skeleton attached to my motor bike.

The access to get on with center stand down would be open a fish fabric print cloth I have by sewn on sleeves and button snaps that would assemble the skin and a door to get to the banana. With me standing with center stand down I would have enough room to close the button snaps and complete the fish skin and the put the center stand down.

Then starting the engine and then all I need is krill to find in a 50 thousand year old dry lake bed up at 8 thousand feet? I don’t know if I’ll need to re-jet with this altitude, but I’ll want the engine cool as can be, so extra rich not too bad. The top of the fabric and bottom, back and belly of fish, will be open to the air for cooling. Maybe add gill slits in the fabric too?

The exhaust will be extended out and up right behind the banana seat with a screen guard. Swinging one leg behind the seat's sissy bar even though it does not extend with a back rest or anything cannot be done as the exhaust will be the stopping that access just the same. I have tried getting on the bike from left or right, so that by lift one leg across the banana seat and it can be done well enough not to worry about the exhaust placement for when in art fish mobile mode.

For OHV (to get DMV sticker to ride in woods) I’m yet to see if the muffler when only just under back of the seat does not heat the tire or me (above on seat) enough to have to re-think that approach. It is quite low noise with the copper flex exhaust and I’ll be seeing about better gasket just made of copper only and or copper sandwich with high temp forma-gasket 700F. Alone the forma-gasket cannot handle the thickness and be rigid enough not to twist out of place (not actually rip) when the connection is a coupling using twist and press.

This is unlike a head gasket or flange connection to muffler that is compression only. The original gasket would melt it can only handle hot water which to me means below steam temp at 212F. The original gasket was much more rigid and would compress with a lot off pressure only, but cannot use it since the temp rating.

There was a nylon sleeve (if you look back a few pages the post pictures) was removed as I'm not putting the pipe in a house where electrolysis could corrode due to connections of the pipe to other fittings. The stuff would also melt and it was not necessary for sealing the exhaust fumes, only the actual gasket needed to be replaced with a high temp rate one that I have to perfect.

The use of regular head gasket material two or three fold does make the thickness and does not squish out of place, but assembling and disassembling does tend to rip the outer one edge where it is on the side that twists (the coupler screw).

The water pipe material (copper corrugated) changed color a bit with a short test, but am sort in the belief that no harm will really come to the copper exhaust.

Onward to fin-ish-ing the bike

MT

The large 3/8 thread and coupler could be good enough for possible side car later if I think maybe I'll do that also. Is there such a thing as two side cars left and right sides? I suppose the 4 wheeler would be a kind of trike with another 4th wheel to propel between the two out rigger side car wheels?

Anyway not shown yet to glue to the couplers are these wood dowels covered with some kind of plastic laminate. I scavenged from the dumpster which is part of a collapsible drying rack, these dowels that have end parts that snap on and off. Then I would just leave the coupler or half the coupler as they are longer than needed in place with a short piece of threaded rod and lock washer and I could put the dowels on and remove easily.

Then I’m not yet sure how the ends of the dowels will connect. Maybe like Tinker Toy, or something else and they will be at right angle to the outward facing dowels making a fish skeleton attached to my motor bike.

The access to get on with center stand down would be open a fish fabric print cloth I have by sewn on sleeves and button snaps that would assemble the skin and a door to get to the banana. With me standing with center stand down I would have enough room to close the button snaps and complete the fish skin and the put the center stand down.

Then starting the engine and then all I need is krill to find in a 50 thousand year old dry lake bed up at 8 thousand feet? I don’t know if I’ll need to re-jet with this altitude, but I’ll want the engine cool as can be, so extra rich not too bad. The top of the fabric and bottom, back and belly of fish, will be open to the air for cooling. Maybe add gill slits in the fabric too?

The exhaust will be extended out and up right behind the banana seat with a screen guard. Swinging one leg behind the seat's sissy bar even though it does not extend with a back rest or anything cannot be done as the exhaust will be the stopping that access just the same. I have tried getting on the bike from left or right, so that by lift one leg across the banana seat and it can be done well enough not to worry about the exhaust placement for when in art fish mobile mode.

For OHV (to get DMV sticker to ride in woods) I’m yet to see if the muffler when only just under back of the seat does not heat the tire or me (above on seat) enough to have to re-think that approach. It is quite low noise with the copper flex exhaust and I’ll be seeing about better gasket just made of copper only and or copper sandwich with high temp forma-gasket 700F. Alone the forma-gasket cannot handle the thickness and be rigid enough not to twist out of place (not actually rip) when the connection is a coupling using twist and press.

This is unlike a head gasket or flange connection to muffler that is compression only. The original gasket would melt it can only handle hot water which to me means below steam temp at 212F. The original gasket was much more rigid and would compress with a lot off pressure only, but cannot use it since the temp rating.

There was a nylon sleeve (if you look back a few pages the post pictures) was removed as I'm not putting the pipe in a house where electrolysis could corrode due to connections of the pipe to other fittings. The stuff would also melt and it was not necessary for sealing the exhaust fumes, only the actual gasket needed to be replaced with a high temp rate one that I have to perfect.

The use of regular head gasket material two or three fold does make the thickness and does not squish out of place, but assembling and disassembling does tend to rip the outer one edge where it is on the side that twists (the coupler screw).

The water pipe material (copper corrugated) changed color a bit with a short test, but am sort in the belief that no harm will really come to the copper exhaust.

Onward to fin-ish-ing the bike

MT

Attachments

Last edited:

MEASURE TWICE

Well-Known Member

Help! Art Fish Mobile Motor Bike prior Motor Bike DIY'er build to add side car maybe?

I'm practically ready for test with dual jack shafts. I found I needed a spacer and used a thin large diameter nut that fit over the 5/8 inch jack shaft to space between the split locking collars that keep the pillow bearings and jack shaft itself in place. I tried to find a washer, but the inner and outer diameter size was not easy to find. Even though the nut has threads it slips over the jack shaft. The fact that it is slightly too large to fit snug makes no difference since it does not scrape. The nut has to be able to not move about when running and the sideways force of the tightened split collar on it to push up against the pillow bearing surface that spins keeps it in place so this is not a problem either.

The previous collars were with the set screw that hits and mars the jack shaft so I went with the split collar where the set screw on it is at a tangent and does not touch the jack shaft.

The problem was that the split collar outer diameter was just a bit larger and scrapes the outer non moveable edge of the pillow bearing. This took care of that issue.

I was only wheeling the bike around and the engine was not running so it did not even make much a scraping sound and no harm came to the parts, but I have it fixed now.

I also mentioned earlier that I got a new pawl clutch for the recoil starter since over run condition causing recoil rope to shoot out and even shear the key for the flywheel happened. There still is a recoil problem with the rope not going back in and it gets stuck. The pawl clutch is new and lubed and it works fine. The recoil off of the engine goes back in fine. But together it sticks except when the engine starts. I figure the engine vibration is helping it free up and rope goes back in.

What I observed is when recoil is pulling rope back in on a test where engine off switched so will not start, I notice that the pulley in the recoil goes at a slight slant. There is some play in the pulley of the recoil I notice when it is off the engine. All that is below the pulley is the recoil spring. The sheet metal is made so that the spring is underneath but no bearing surfaces so that I guess it has grease and is a bit non-precision. Further I noted is when it goes at a slant and binds while trying to pull the rope back in (which does not seem to happen when I an pulling to start) a line drawn between the up and down points of this slant tilt is always not on the same axis as the two tabs holding the recoil pulley. I thought maybe I should add two more and have four tabs to help it be more even as it goes to pull the rope back in. All but 1 tab was left and I made my own to replace one of the broken tabs so I can make some more.

Anyone have any thoughts on the rope pulling back in problem and the slop in the recoil pulley not being more in a fixed position?

I’m about to let it be as I said when the engine fires up the vibration has caused the sticking recoil to pull back all the way with just minor hesitation. If the engine was hard to start then this would be an issue as I would have to tap on the pulley to get the tilt out to free it up as recoil was not happening and the engine was not yet started and warmed up. The part for an 80202 0430 Briggs 3hp side shaft engine if possibly available new or used might be an answer, but I would like to know what is with the one I have. It is not rocket science, at least I think not?

One last thing I did was put a few more turns of the recoil spring on it, but it did not help. It could be maybe the spring is worn and the not perfect design, by design without bearing surfaces in the recoil might justify needing to replace a spring now and then when spring is not as springy as it were when it was new?

MT

I'm practically ready for test with dual jack shafts. I found I needed a spacer and used a thin large diameter nut that fit over the 5/8 inch jack shaft to space between the split locking collars that keep the pillow bearings and jack shaft itself in place. I tried to find a washer, but the inner and outer diameter size was not easy to find. Even though the nut has threads it slips over the jack shaft. The fact that it is slightly too large to fit snug makes no difference since it does not scrape. The nut has to be able to not move about when running and the sideways force of the tightened split collar on it to push up against the pillow bearing surface that spins keeps it in place so this is not a problem either.

The previous collars were with the set screw that hits and mars the jack shaft so I went with the split collar where the set screw on it is at a tangent and does not touch the jack shaft.

The problem was that the split collar outer diameter was just a bit larger and scrapes the outer non moveable edge of the pillow bearing. This took care of that issue.

I was only wheeling the bike around and the engine was not running so it did not even make much a scraping sound and no harm came to the parts, but I have it fixed now.

I also mentioned earlier that I got a new pawl clutch for the recoil starter since over run condition causing recoil rope to shoot out and even shear the key for the flywheel happened. There still is a recoil problem with the rope not going back in and it gets stuck. The pawl clutch is new and lubed and it works fine. The recoil off of the engine goes back in fine. But together it sticks except when the engine starts. I figure the engine vibration is helping it free up and rope goes back in.

What I observed is when recoil is pulling rope back in on a test where engine off switched so will not start, I notice that the pulley in the recoil goes at a slight slant. There is some play in the pulley of the recoil I notice when it is off the engine. All that is below the pulley is the recoil spring. The sheet metal is made so that the spring is underneath but no bearing surfaces so that I guess it has grease and is a bit non-precision. Further I noted is when it goes at a slant and binds while trying to pull the rope back in (which does not seem to happen when I an pulling to start) a line drawn between the up and down points of this slant tilt is always not on the same axis as the two tabs holding the recoil pulley. I thought maybe I should add two more and have four tabs to help it be more even as it goes to pull the rope back in. All but 1 tab was left and I made my own to replace one of the broken tabs so I can make some more.

Anyone have any thoughts on the rope pulling back in problem and the slop in the recoil pulley not being more in a fixed position?

I’m about to let it be as I said when the engine fires up the vibration has caused the sticking recoil to pull back all the way with just minor hesitation. If the engine was hard to start then this would be an issue as I would have to tap on the pulley to get the tilt out to free it up as recoil was not happening and the engine was not yet started and warmed up. The part for an 80202 0430 Briggs 3hp side shaft engine if possibly available new or used might be an answer, but I would like to know what is with the one I have. It is not rocket science, at least I think not?

One last thing I did was put a few more turns of the recoil spring on it, but it did not help. It could be maybe the spring is worn and the not perfect design, by design without bearing surfaces in the recoil might justify needing to replace a spring now and then when spring is not as springy as it were when it was new?

MT

Last edited:

MEASURE TWICE

Well-Known Member

I just realized that when I had the three bolts off the shroud and tested the recoil on the Briggs engine and it stuck on recoil, if I put pressure at various points on the shroud it would unstuck completely or some anyway.

As I said when the engine starts up the vibration probably has something to do with the recoil being cajoled into going back in.

Now I am remembering that since I had to make to replacement places of the lower two fasteners to the cover when the metal rusted away, the location where I tried duplicating them may not be precisely the same as where they should be.

When I observed the recoil with the spark plug wire off so it would not start and looked at the recoil and I saw when it stuck the pulley was on a slant. The slant I thought might be since there could be a need for more than two tabs holding in the pulley so it would stay level. I was ready to buy another used cover, but since my cover has been modified for much more than just the two missing lower fastener points, it would not be in my best interest to get another part, that is a used recoil with cover.

I saw on Ebay a used part for 13 dollars ans 10 dollar shipping, but I noticed it had just two tabs in use for holding the pulley in the cover. There were two additional unused tabs adjacent to the ones in use. I then realized there is no need to have more in use it should stay level with how it was designed.

Now I realized that one of my two lower replacement fastener points for the cover is not rigid enough as well as the accuracy of the position where it should fasten to. I think this slight amount causes the tilt and it sticks. In addition since the pawl clutch is new and lubed well as is the recoil and they both operate perfect separately the tilt when sticking is the key to where the problem lies.

Mounted over the pawl clutch to the recoil starter to keep fingers and other foreign matter is a round screen. If I heard scraping of the flywheel on the cover I knew it was miss-aligned so I adjusted my replacement fastener locations. Also looking at the screen to see that it was centered in the cover under the recoil I also did. This would seem to be enough, but it was not.

Mentioned above is alignment in a 360 degree on one axis. As I know a tilt of just the slightest degree causes what was hard to see. It was tilt which puts it on another axis. The pawl clutch is new and it has not been in use but just two or three times to see that over running (spitting out the rope and shearing flywheel key once) does not happen anymore.

When I go to fix the alignment and make it more rigid and the pawl clutch which is still fine as is the recoil, then when assembled together there should be no tilt which makes more friction on the recoil and the pawl clutch and causes recoil to stick.

I’m going look at how I can get at least one of the brackets I made to replace where the two lower ¼ - 20 bolts used to have mounting spots on the casting be better in rigidity and preciseness in alignment to fix this problem.

===========================================

The recoil going back in fixed itself. I suspect really not, but just that the lubrication had time to penetrate and so it works fine and is not an issue now! Wheew!!!

MT

As I said when the engine starts up the vibration probably has something to do with the recoil being cajoled into going back in.

Now I am remembering that since I had to make to replacement places of the lower two fasteners to the cover when the metal rusted away, the location where I tried duplicating them may not be precisely the same as where they should be.

When I observed the recoil with the spark plug wire off so it would not start and looked at the recoil and I saw when it stuck the pulley was on a slant. The slant I thought might be since there could be a need for more than two tabs holding in the pulley so it would stay level. I was ready to buy another used cover, but since my cover has been modified for much more than just the two missing lower fastener points, it would not be in my best interest to get another part, that is a used recoil with cover.

I saw on Ebay a used part for 13 dollars ans 10 dollar shipping, but I noticed it had just two tabs in use for holding the pulley in the cover. There were two additional unused tabs adjacent to the ones in use. I then realized there is no need to have more in use it should stay level with how it was designed.

Now I realized that one of my two lower replacement fastener points for the cover is not rigid enough as well as the accuracy of the position where it should fasten to. I think this slight amount causes the tilt and it sticks. In addition since the pawl clutch is new and lubed well as is the recoil and they both operate perfect separately the tilt when sticking is the key to where the problem lies.

Mounted over the pawl clutch to the recoil starter to keep fingers and other foreign matter is a round screen. If I heard scraping of the flywheel on the cover I knew it was miss-aligned so I adjusted my replacement fastener locations. Also looking at the screen to see that it was centered in the cover under the recoil I also did. This would seem to be enough, but it was not.

Mentioned above is alignment in a 360 degree on one axis. As I know a tilt of just the slightest degree causes what was hard to see. It was tilt which puts it on another axis. The pawl clutch is new and it has not been in use but just two or three times to see that over running (spitting out the rope and shearing flywheel key once) does not happen anymore.

When I go to fix the alignment and make it more rigid and the pawl clutch which is still fine as is the recoil, then when assembled together there should be no tilt which makes more friction on the recoil and the pawl clutch and causes recoil to stick.

I’m going look at how I can get at least one of the brackets I made to replace where the two lower ¼ - 20 bolts used to have mounting spots on the casting be better in rigidity and preciseness in alignment to fix this problem.

===========================================

The recoil going back in fixed itself. I suspect really not, but just that the lubrication had time to penetrate and so it works fine and is not an issue now! Wheew!!!

MT

Last edited:

MEASURE TWICE

Well-Known Member

Ignition toggle stop switch and push button stop switch wired up nice. I had a problem with the push button switch where the strap was two long (diameter) and the tightness could not fasten at all. Old style handlebar diameter was just too small. I cut up 4 strips of a beer can and electric taped around the bar to make the right diameter.

I do know that there would be no ground for the push button switch with the aluminum can with plastic coating inside and the electrical tape, but since I intended on running a pair of wires being one from coil and other from laminations on the coil it will be OK. I used an external start tooth lock washer already with ring terminal soldered and mounted to the same screw that attaches the push button stop switch.

When I wire the ground direct to the coil laminations I also will use and external start tooth lock washer.

Besides working on the cover for the recoil problem to fix, I will also either weld a plate or fasten with bolts to make a nice place for the fuel line metal valve I got to mount under the gas tank.

The brakes and throttle cables are routed and look good now.

The twist grip throttle had not enough friction on the plastic sort of cone shape part that the replaceable grip goes over. See this useful tip I heard from a professional BMX custom bike builder from a PBS TV show where kids are asked to write in question on how stuff is done.

Curiosity Quest show is where I saw the guy use hair spray as a glue and he also mentioned that the grips can be put on an pulled off best by use of compressed air. I could have done that, but since the grip was not very tight and the return spring on my throttle had it slipping back toward idle while I hand been trying to accelerate I could do without that.

I just used the hair spray and let dry indoor room temp for two days. Perfect! I also found some spray glue I had for mounting pictures, but I already used what I had. The stuff for pictures is probably way more expensive as it is supposed to not yellow though the back of the print to mar up a picture.

MT

I do know that there would be no ground for the push button switch with the aluminum can with plastic coating inside and the electrical tape, but since I intended on running a pair of wires being one from coil and other from laminations on the coil it will be OK. I used an external start tooth lock washer already with ring terminal soldered and mounted to the same screw that attaches the push button stop switch.

When I wire the ground direct to the coil laminations I also will use and external start tooth lock washer.

Besides working on the cover for the recoil problem to fix, I will also either weld a plate or fasten with bolts to make a nice place for the fuel line metal valve I got to mount under the gas tank.

The brakes and throttle cables are routed and look good now.

The twist grip throttle had not enough friction on the plastic sort of cone shape part that the replaceable grip goes over. See this useful tip I heard from a professional BMX custom bike builder from a PBS TV show where kids are asked to write in question on how stuff is done.

Curiosity Quest show is where I saw the guy use hair spray as a glue and he also mentioned that the grips can be put on an pulled off best by use of compressed air. I could have done that, but since the grip was not very tight and the return spring on my throttle had it slipping back toward idle while I hand been trying to accelerate I could do without that.

I just used the hair spray and let dry indoor room temp for two days. Perfect! I also found some spray glue I had for mounting pictures, but I already used what I had. The stuff for pictures is probably way more expensive as it is supposed to not yellow though the back of the print to mar up a picture.

MT

MEASURE TWICE

Well-Known Member

Finish the dual jack shaft and cover and tank valve ect. No problem some how the recoil had freed up and didn't need any attention.

I need to find a quick way to reduce the pixels on pictures after they have been taken. I cannot post them as there too large. Need freeware or something I already have in some utility like word, paint ect?

MT

Fish cover starting. Need two more weld on threads to the back of the frame next to drop outs so I can make skeleton frame for fish fabric cover.

I need to find a quick way to reduce the pixels on pictures after they have been taken. I cannot post them as there too large. Need freeware or something I already have in some utility like word, paint ect?

MT

Fish cover starting. Need two more weld on threads to the back of the frame next to drop outs so I can make skeleton frame for fish fabric cover.

MEASURE TWICE

Well-Known Member

High Temp Gasket Smasket! I kept seeing the high temp fiber gasket crumble used in my flex copper corrugated water pipe from adapters from exhaust port on engine and also at muffler.

Copper High Temp Form-a-gasket was just too soft. It would not take the pressure from the couplings without moving out of place. I'll need about ten of these copper gaskets I made for each connection to seal with enough thickness. I used a hole saw and smoothed the edges. Next not in picture I made a circle trace around the cut out hole with enough width for the gasket by cutting with a foot long metal hand shears I have. Then I smoothed the edges on that too.

I really wanted to get two more weld on threads on the frame as bosses to mount the skeleton structure for the California Sheepshead fish covering that would be for parades, but had to fix the gaskets in the exhaust issue first.

Note the donut shapes next to the shears are not the gaskets. The gaskets are not shown. Later pics of them. The donut shapes are just since the hole saw has a pilot drill in the center. These I suppose I could recycle

The orange stuff is the gasket I made from high temp copper Form-a-gasket in a mold I made, but it was so soft when fully cured it was of no use. Too much space needs to be filled and needs to be more rigid. I could not buy the fiber stuff with a metalized covering at a decent price and also the thickness would be next to impossible to find so 10ea of these copper gasket go in the end of copper water pipe with adapter to exhaust threads on the Briggs engine and spark arrestor muffler. It sound quiet and also did not rob power as far as I can tell. The gaskets when done I expect to last near forever!

The temperature of the bottom side of the banana seat only is warm after 10 minutes of the engine running. The muffler is way hot though and only 2 inches away from the underside of the seat. I will be continuing to monitor this and will make the muffler stick out behind the seat if necessary. So far this is not the case. I also have one of those screens they use in the guttering on house roofs, the drain pipes using a screen to keep leaves out. It will make it such a good cover exact almost to the size of the muffler. I need to wire it in place and the touching the screen still has an inch distance away from the hot muffler so mo burns. The exhaust pipe also will have some screen I intend to have covered as it is just as hot as the muffler.

I thought of adding some kind of heat sink fins and that they in-themselves would provide cooling and fingers touching them would not be as hot and you could not touch the exhaust pipe directly. Cooling suppose to enhance horse power somehow? Most likely will do some screen cover over exhaust pipe and keep it simple.

Other pics show the metal fuel valve mounted underneath the gas tank. The routing of the fuel line goes up but only about 2/3 the height of the max fuel level of the gas tank. Then it goes a few inches below the bottom outlet of the gas tank into the carb fuel inlet. I have to prime the fuel line when ever I fully empty the gas tank, but not a big deal. I got this one for about 7 dollars but had to pay about that in shipping. Still I like this better than using a 5 dollar plastic valve for safety sake.

MT

Copper High Temp Form-a-gasket was just too soft. It would not take the pressure from the couplings without moving out of place. I'll need about ten of these copper gaskets I made for each connection to seal with enough thickness. I used a hole saw and smoothed the edges. Next not in picture I made a circle trace around the cut out hole with enough width for the gasket by cutting with a foot long metal hand shears I have. Then I smoothed the edges on that too.

I really wanted to get two more weld on threads on the frame as bosses to mount the skeleton structure for the California Sheepshead fish covering that would be for parades, but had to fix the gaskets in the exhaust issue first.

Note the donut shapes next to the shears are not the gaskets. The gaskets are not shown. Later pics of them. The donut shapes are just since the hole saw has a pilot drill in the center. These I suppose I could recycle

The orange stuff is the gasket I made from high temp copper Form-a-gasket in a mold I made, but it was so soft when fully cured it was of no use. Too much space needs to be filled and needs to be more rigid. I could not buy the fiber stuff with a metalized covering at a decent price and also the thickness would be next to impossible to find so 10ea of these copper gasket go in the end of copper water pipe with adapter to exhaust threads on the Briggs engine and spark arrestor muffler. It sound quiet and also did not rob power as far as I can tell. The gaskets when done I expect to last near forever!

The temperature of the bottom side of the banana seat only is warm after 10 minutes of the engine running. The muffler is way hot though and only 2 inches away from the underside of the seat. I will be continuing to monitor this and will make the muffler stick out behind the seat if necessary. So far this is not the case. I also have one of those screens they use in the guttering on house roofs, the drain pipes using a screen to keep leaves out. It will make it such a good cover exact almost to the size of the muffler. I need to wire it in place and the touching the screen still has an inch distance away from the hot muffler so mo burns. The exhaust pipe also will have some screen I intend to have covered as it is just as hot as the muffler.

I thought of adding some kind of heat sink fins and that they in-themselves would provide cooling and fingers touching them would not be as hot and you could not touch the exhaust pipe directly. Cooling suppose to enhance horse power somehow? Most likely will do some screen cover over exhaust pipe and keep it simple.

Other pics show the metal fuel valve mounted underneath the gas tank. The routing of the fuel line goes up but only about 2/3 the height of the max fuel level of the gas tank. Then it goes a few inches below the bottom outlet of the gas tank into the carb fuel inlet. I have to prime the fuel line when ever I fully empty the gas tank, but not a big deal. I got this one for about 7 dollars but had to pay about that in shipping. Still I like this better than using a 5 dollar plastic valve for safety sake.

MT

Attachments

Last edited:

MEASURE TWICE

Well-Known Member

MEASURE TWICE

Well-Known Member

Some pics of the exhaust pipe and the copper gaskets I made to replace the parts that the water pipe originally comes with (rubber.. melts.. burns). Also the high temp gasket material still would not do, so think copper sheet did fine.

MT

MT