Bikeguy Joe

Godfather of Motorized Bicycles

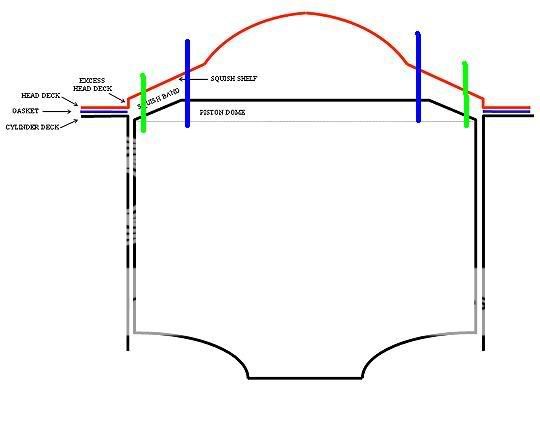

This is the place for posting your photos and results of the transfer port modification.

Do it with a hacksaw, dremel tool or a claw hammer (just kidding GEEZE!)

CAUTION TO INEXPERIENCED BIKE BUILDERS- This modification is for those that have a rudimentary knowledge of the two stroke engine, and is not suggested as a first timer's modification.

Do it with a hacksaw, dremel tool or a claw hammer (just kidding GEEZE!)

CAUTION TO INEXPERIENCED BIKE BUILDERS- This modification is for those that have a rudimentary knowledge of the two stroke engine, and is not suggested as a first timer's modification.