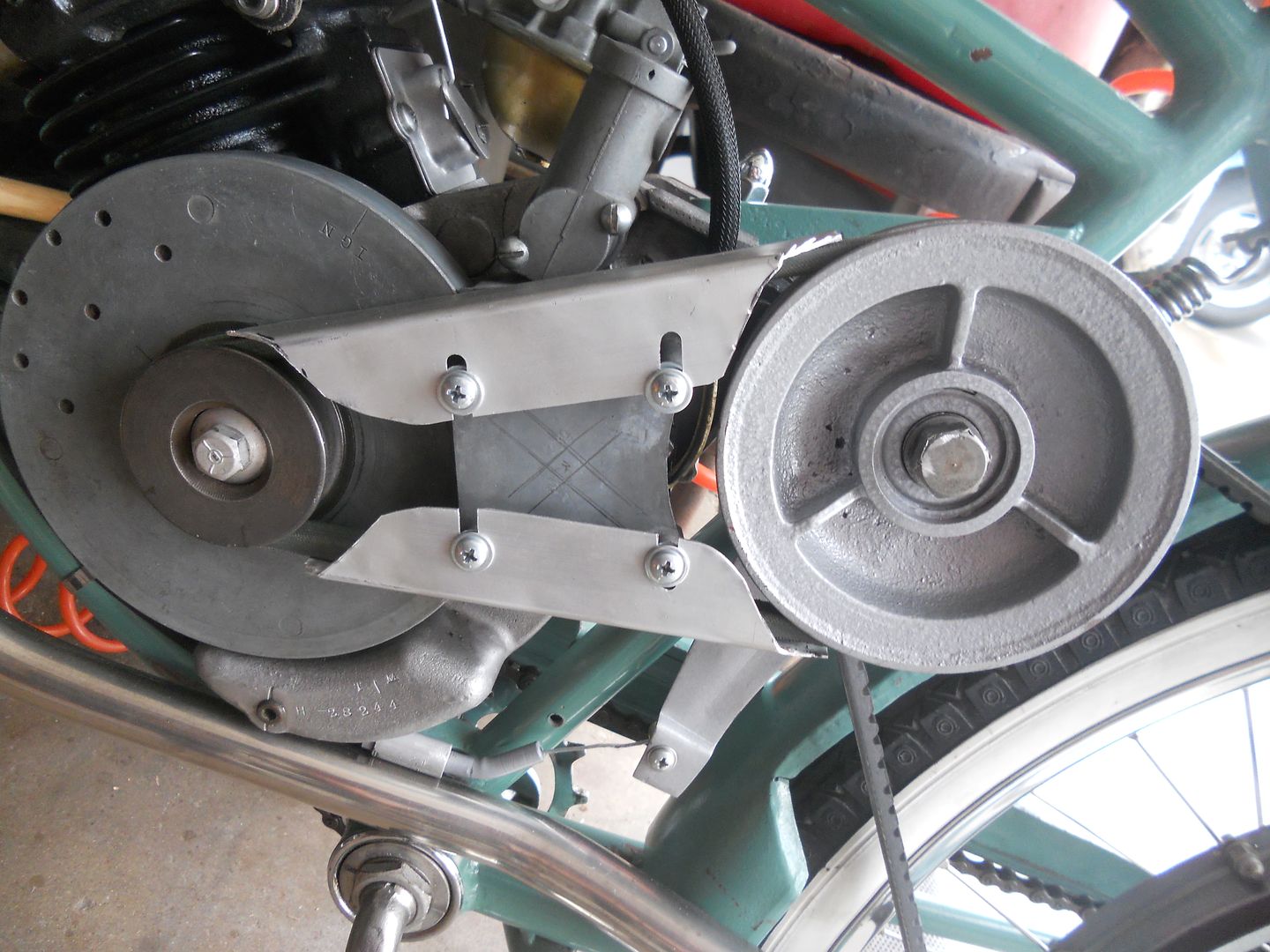

Back when we had several local Whizzer rides a year, I joined maybe a hundred people for a nice long journey through Orange County. Some of the bikes had automatics. I didn't. Frequent adjustment of the primary belt cover became a way of life. Getting it not to rub the pulleys and release the belt so you could idle at a stop light wasn't easy. I found that a large amount of my fellow riders experienced the same frustration. I tried strips of metal pop riveted to the inside of the cover and it helped a little, but didn't really solve the problem. I finally went with automatics. They had their own problems but not like a slipper clutch. Much nicer to ride.

So, the other day I decided to try to figure a way to make them more user friendly.

The problem is the cover is so large, it only addresses one side of the belt, the top or bottom, depending if you have it adjusted up or down. Add an easy glide and there's even less movement to release.

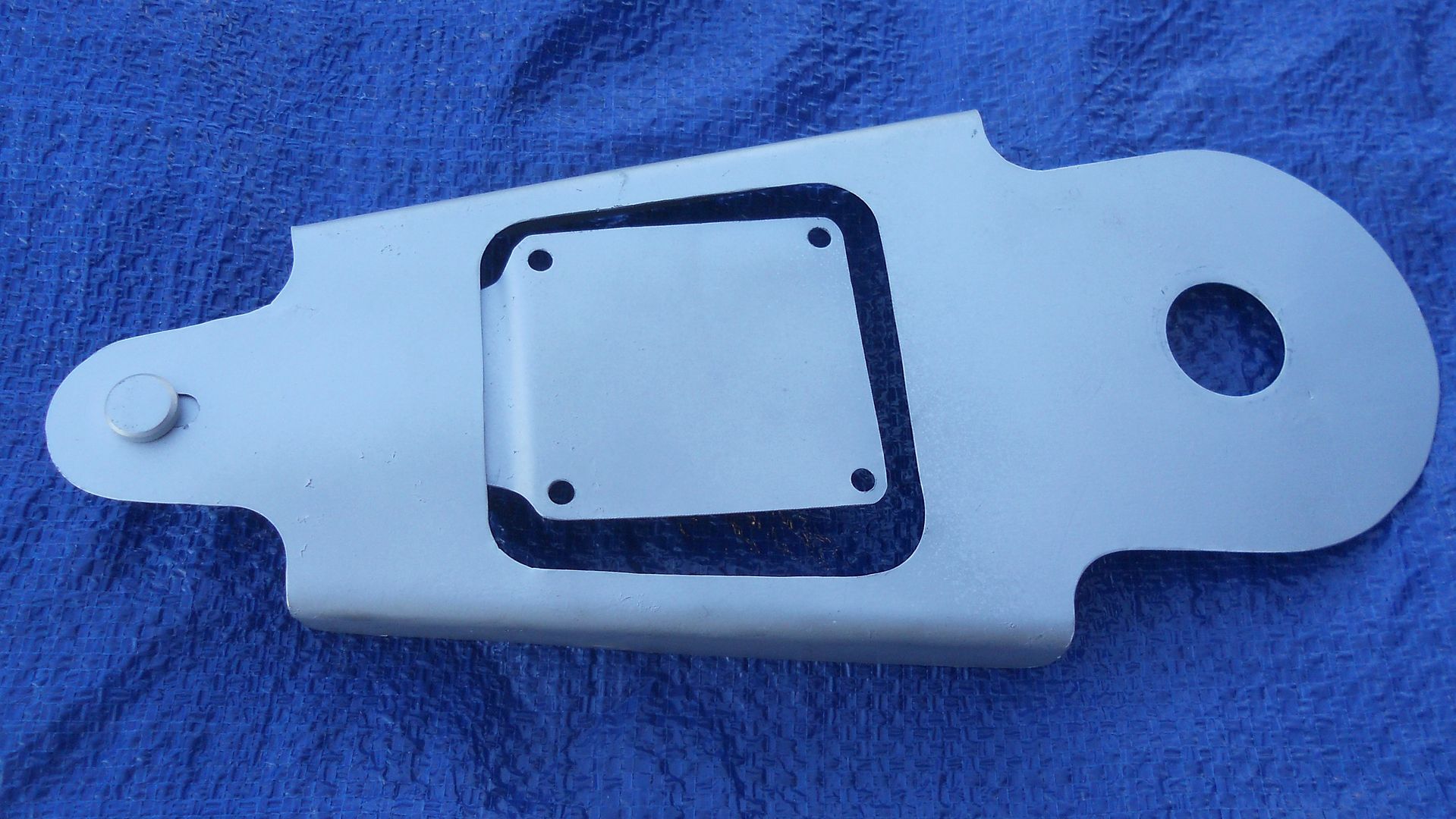

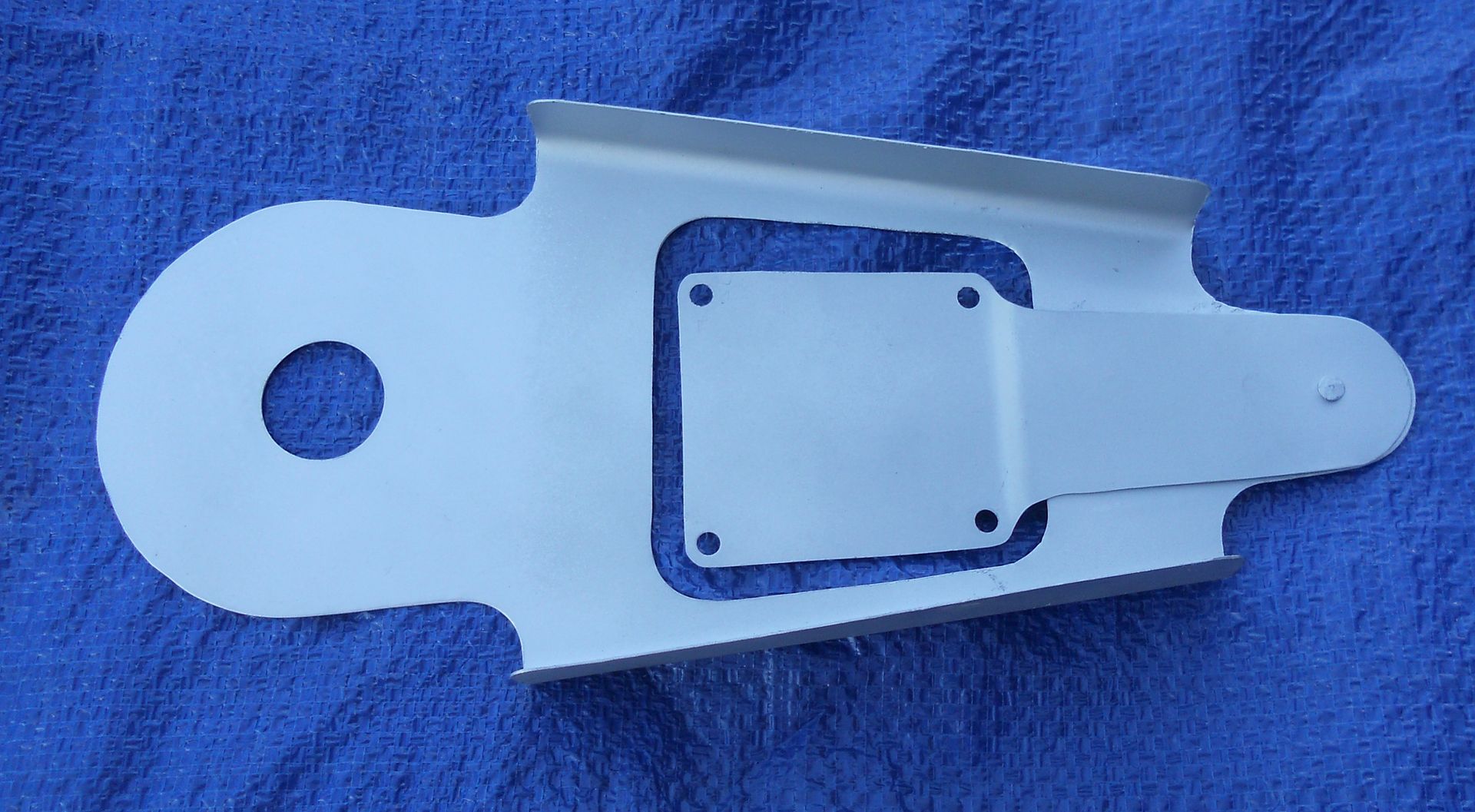

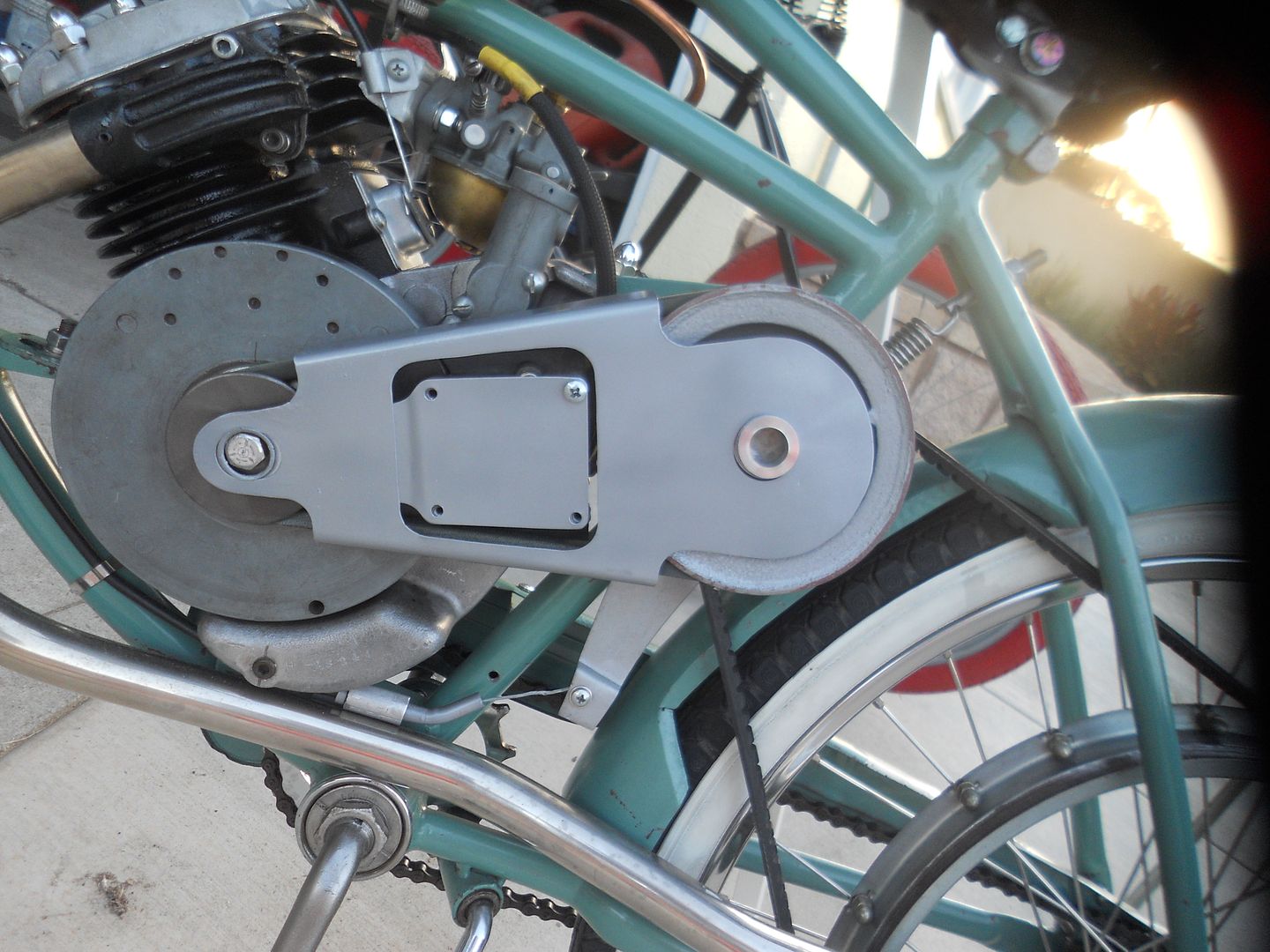

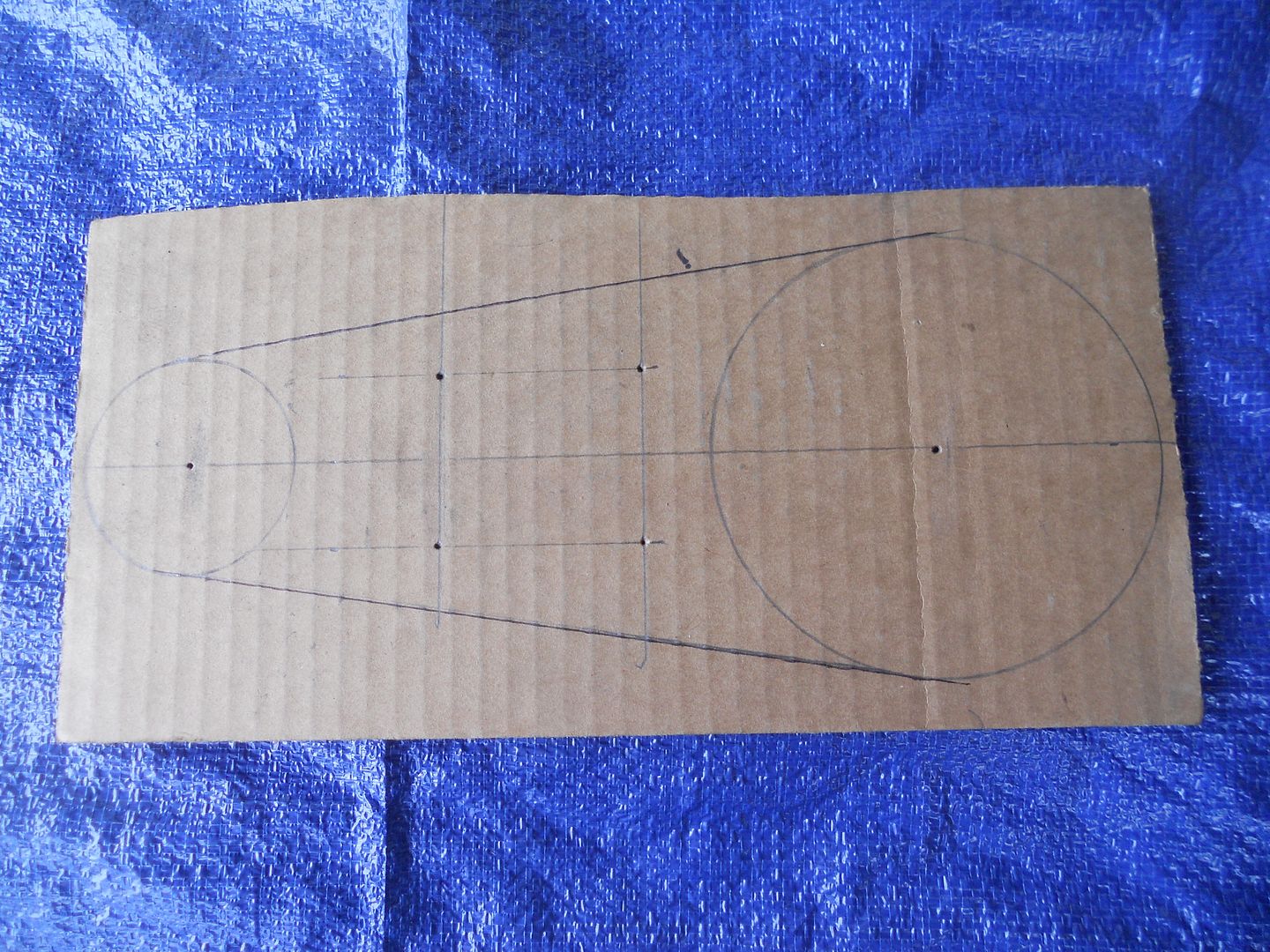

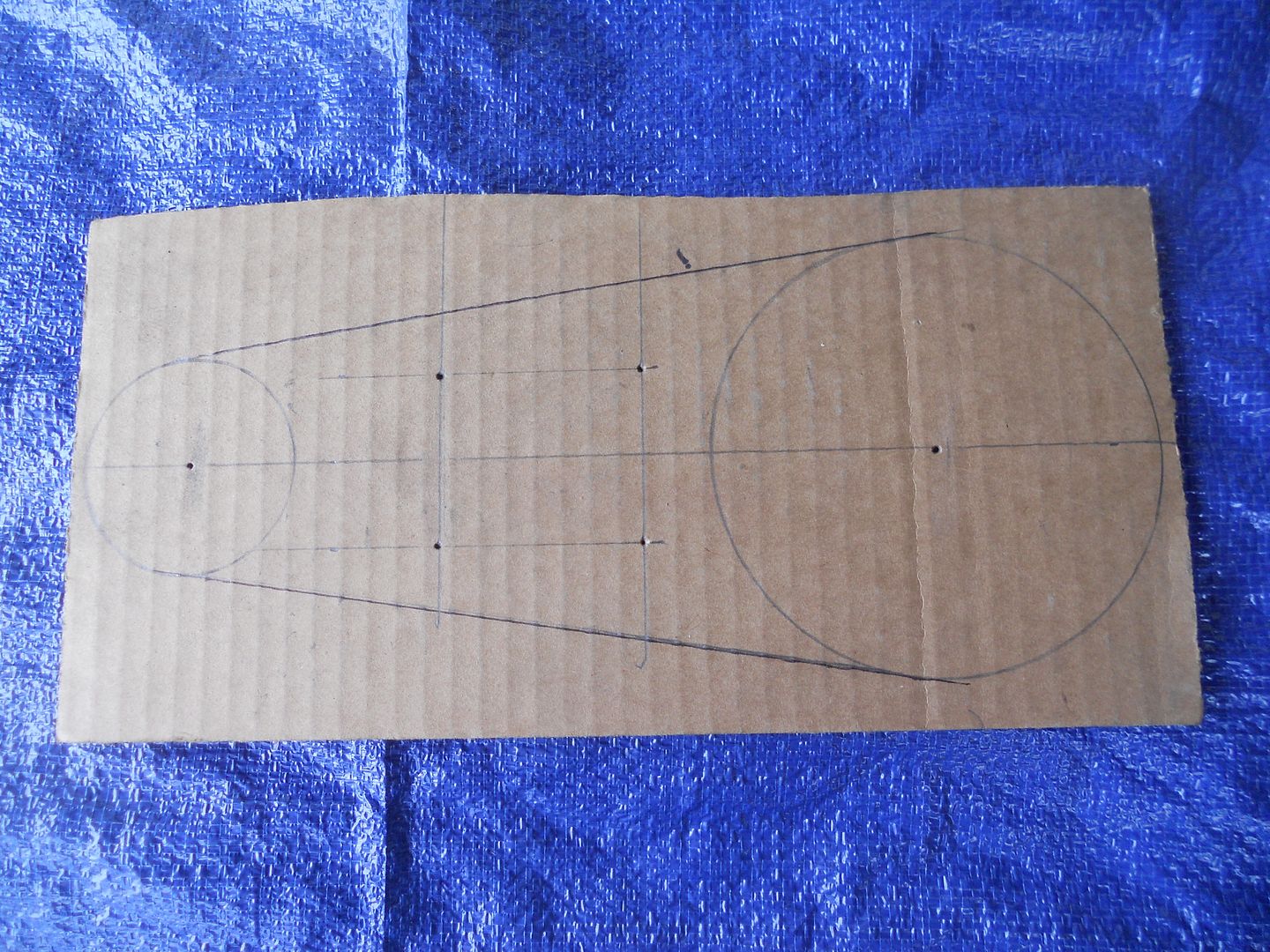

That's when I got an idea for a belt guide narrow enough and the right shape to contain both sides of the belt. I started with an actual size drawing of my pulley locations and the guard mounting bosses.

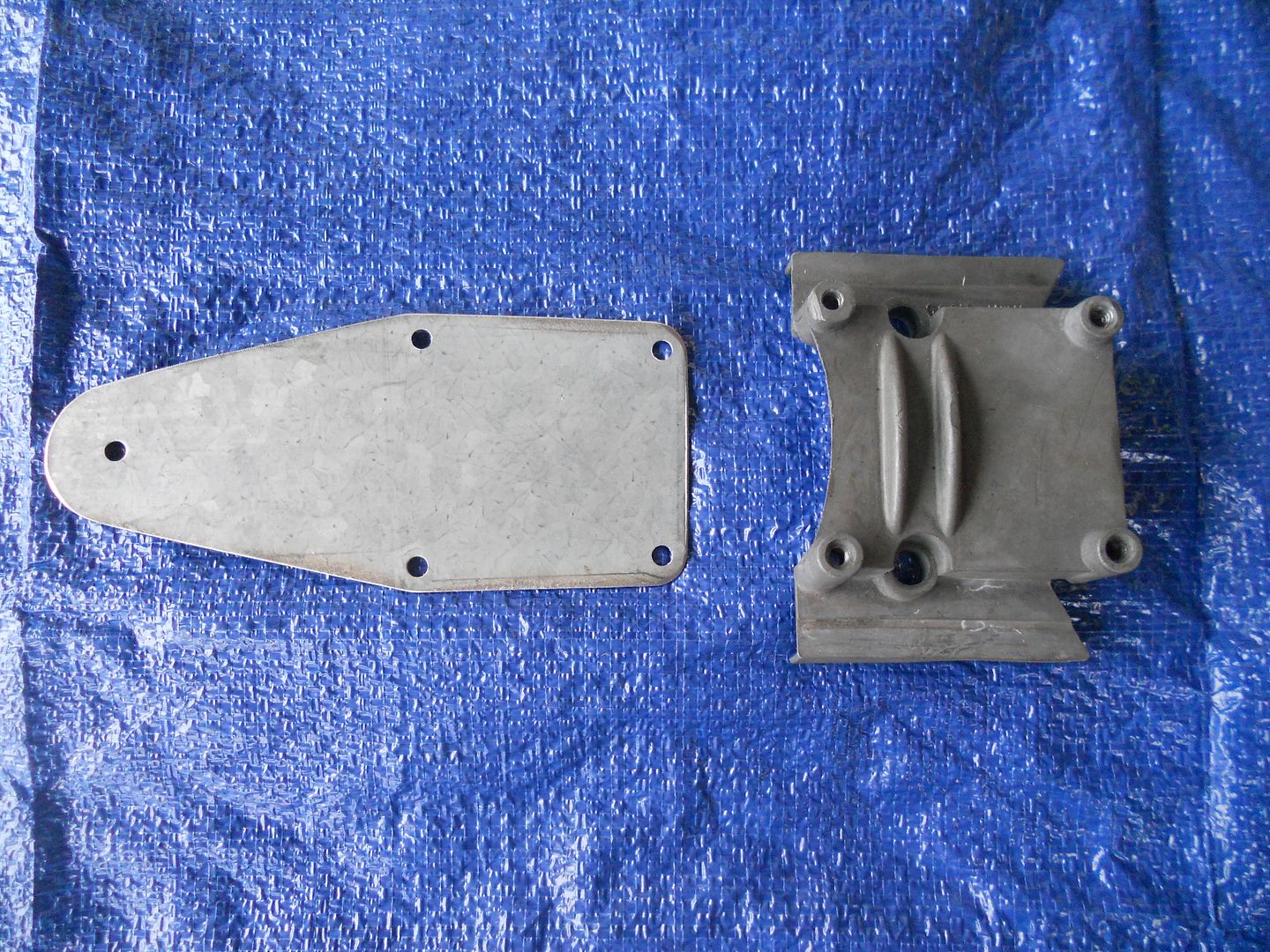

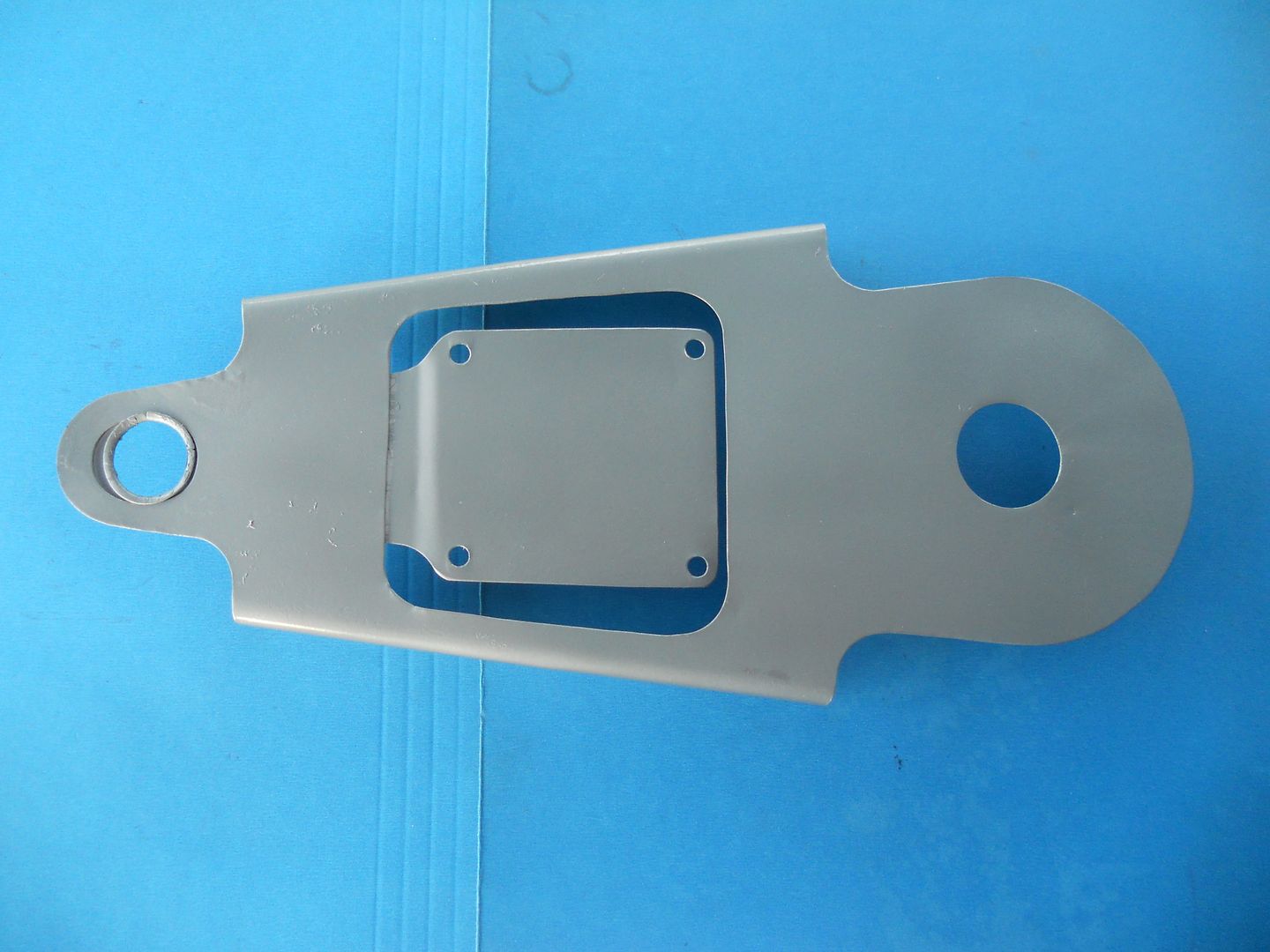

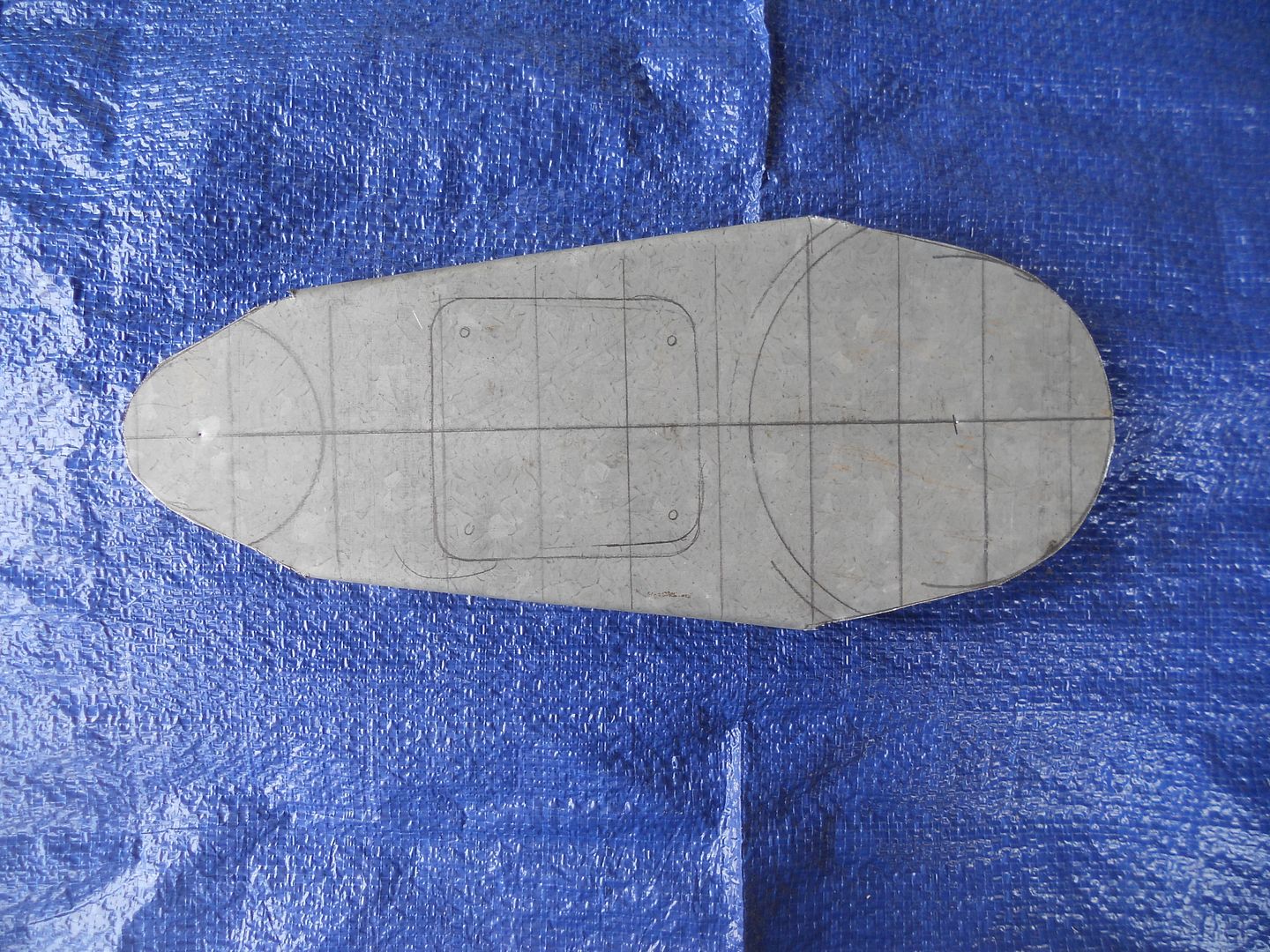

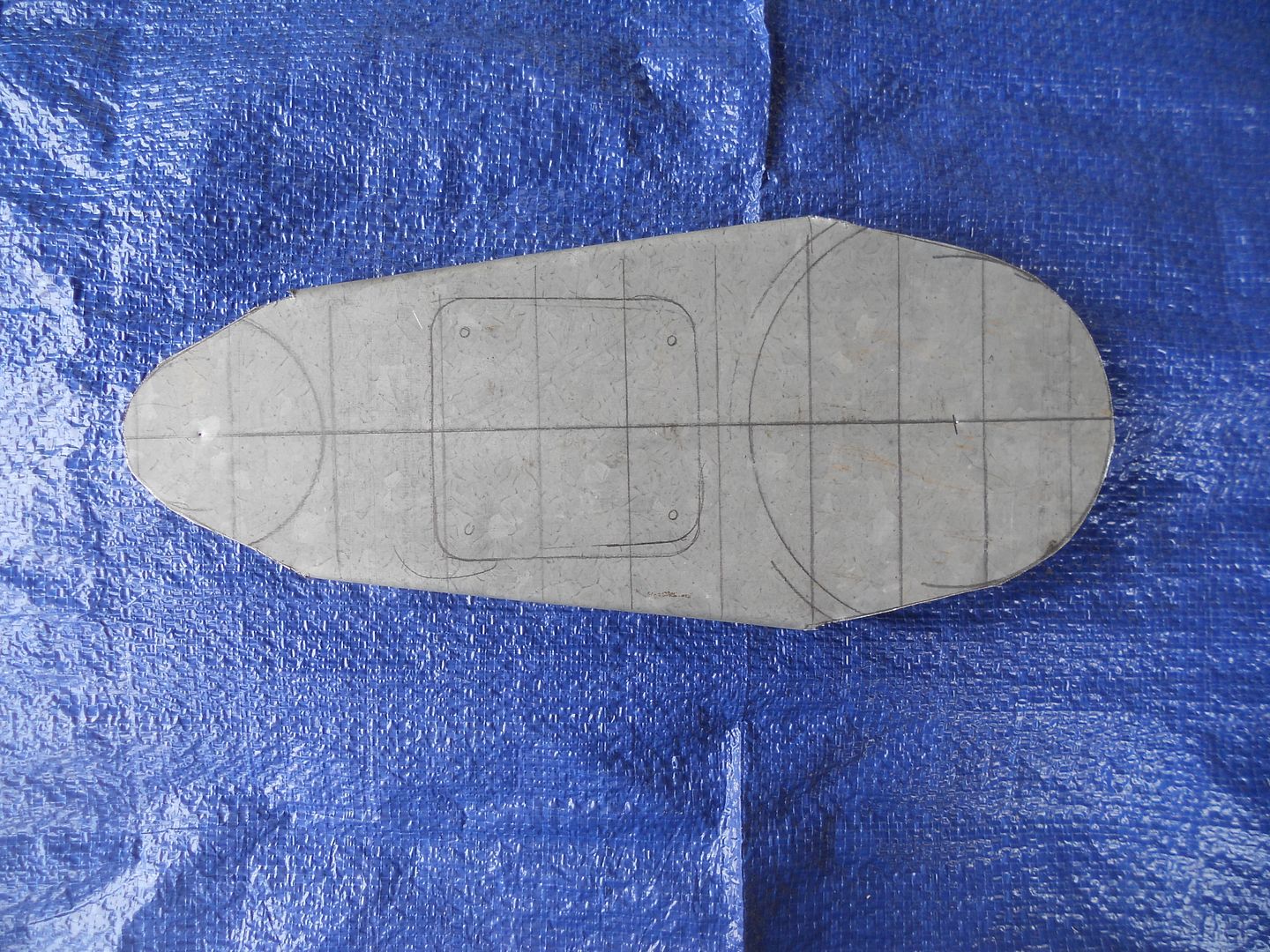

Wanting something that doesn't show, I realized there's very little room to work with. I chose thin gauge sheet metal I had laying around (about .030"), and bent two edges over at the angle of my belt.

Then I fit it onto the pulleys and cut it to size, marking where the mounting holes are.

So, the other day I decided to try to figure a way to make them more user friendly.

The problem is the cover is so large, it only addresses one side of the belt, the top or bottom, depending if you have it adjusted up or down. Add an easy glide and there's even less movement to release.

That's when I got an idea for a belt guide narrow enough and the right shape to contain both sides of the belt. I started with an actual size drawing of my pulley locations and the guard mounting bosses.

Wanting something that doesn't show, I realized there's very little room to work with. I chose thin gauge sheet metal I had laying around (about .030"), and bent two edges over at the angle of my belt.

Then I fit it onto the pulleys and cut it to size, marking where the mounting holes are.

Last edited: