Moisstink

New Member

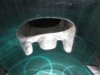

While in comparison a hole would be easier, but what is fifteen minutes with a dremel? You want maximum port timing with reed valves, or so I have read because I am not an expert what-so-ever. A rectangle would optimize your port timing so you can get the maximum amount of fuel and air mix in there. Something like this

I have read through this a couple times and sorry if I am not understanding correctly but I want to dremel a rectangle basically 5/8" x 1" that is 1/4" from the bottom of the piston centered on the intake.

Nothing needs to be exact on this and doing this mod will not negatively affect the running of the engine? I did want to do the simple cleaning out of the flash around the ports so this can be done then as well.

After I am done with that I should do the spark plug test for correct jetting of the carb? Thanks for all the good info I am just hesitant on doing too much on internal mods without understanding the full spectrum of what I am doing.

Last edited: