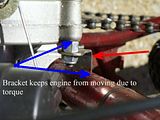

Attached is a photo of the mount I made due to the large amount of space between the motor and frame and (I thought) the need to protect the motor from vibration. It was impossible to get the hole drilled at the exact angle, so the rubber shock-mount compensates.

But- the motor constantly shifts to the port side, more so when I tighten the chain. Should I replace the rubber with some sort of wedge-shaped filler or .....?

Rick in Indiana

But- the motor constantly shifts to the port side, more so when I tighten the chain. Should I replace the rubber with some sort of wedge-shaped filler or .....?

Rick in Indiana