Ever since my Friend Anthony, ''briggsbiker'', made a kicker for his motorized bike, I've been wanting to make a better one. A lot of small engines of all makes have a 4 bolt pattern on the PTO side to attach pumps and other equipment. And some also have a 1/2'' 20 thread hole to the right that Trimmer edgers use for their setup. So I found engineering drawings locating the exact dimensions of the crankshaft hole in relation to the 5 holes I just described. I cut a base plate from 1/4'' steel in a shape to bolt to the engine using the 4 threaded holes. I made a freewheel with a 3/4'' keyed hub welded into it for an earlier project that never got used, so I used it for my Kickstarter. Then I made a blueprint for a segment gear to mesh with it and pivot at the center of the lower right side cover mounting hole. My grandson laser cut a piece from my blueprint and I had all the basic parts to fab the rest.

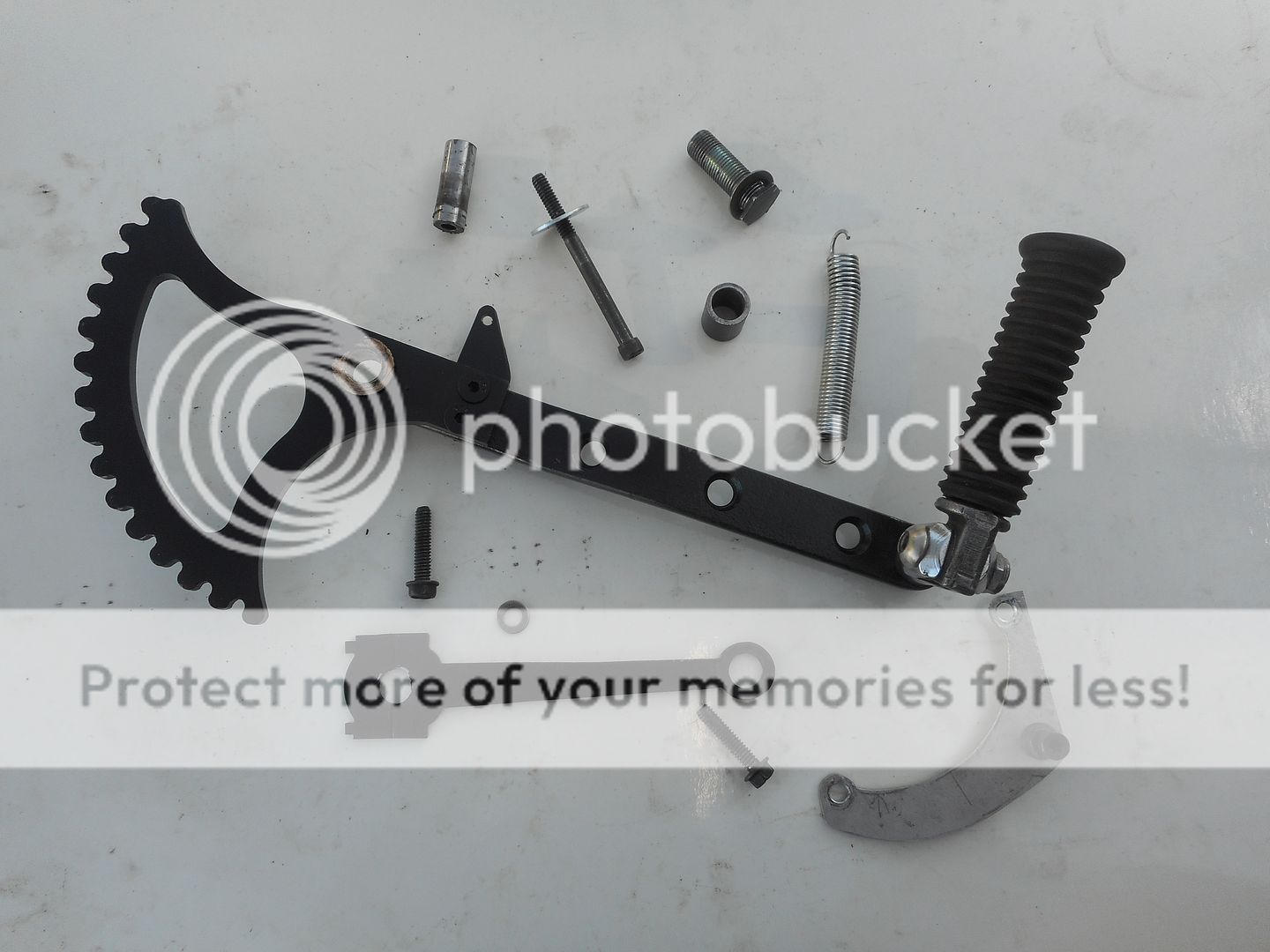

I bolted an arm to the segment gear, attached a folding footpeg for the kicker, along with a few spacers, bushings and brackets to complete the assembly. Added a return spring and began testing.

Everything is on Dave's chopper style bike that is on a build thread in the cruiser category. Still needs some refinements but looks like it's going to work fine. And I have plenty of room for the pulleys and belt for the primary drive as well as an exhaust pipe.

RL=http://s1047.photobucket.com/user/msrfan/media/DSCN7695_zpseeoeie8e.jpg.html]

[/URL]

[/URL]

I bolted an arm to the segment gear, attached a folding footpeg for the kicker, along with a few spacers, bushings and brackets to complete the assembly. Added a return spring and began testing.

Everything is on Dave's chopper style bike that is on a build thread in the cruiser category. Still needs some refinements but looks like it's going to work fine. And I have plenty of room for the pulleys and belt for the primary drive as well as an exhaust pipe.

RL=http://s1047.photobucket.com/user/msrfan/media/DSCN7695_zpseeoeie8e.jpg.html]